V-shaped groove machining, clamping and positioning device for pulley type part

A positioning device and V-groove technology, applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of increased manufacturing costs, difficult clamping safety hazards, waste, etc., to solve the waste of raw materials and eliminate safety Hidden dangers, the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0012] In order to more clearly describe the technical solutions of the embodiments of the present invention, the following will briefly introduce the drawings needed in the embodiments. Obviously, the drawings in the following description are some embodiments of the present invention. Ordinary technicians can obtain other drawings based on these drawings without creative work.

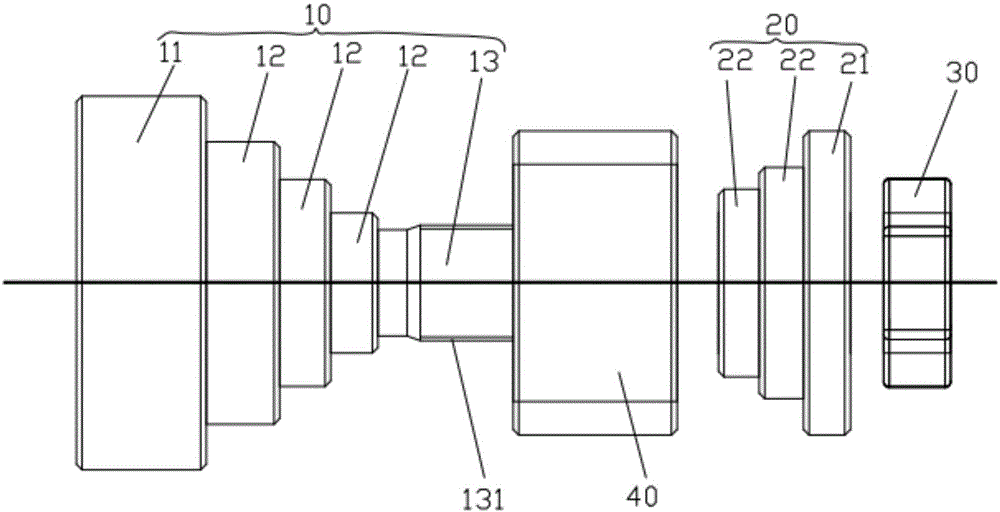

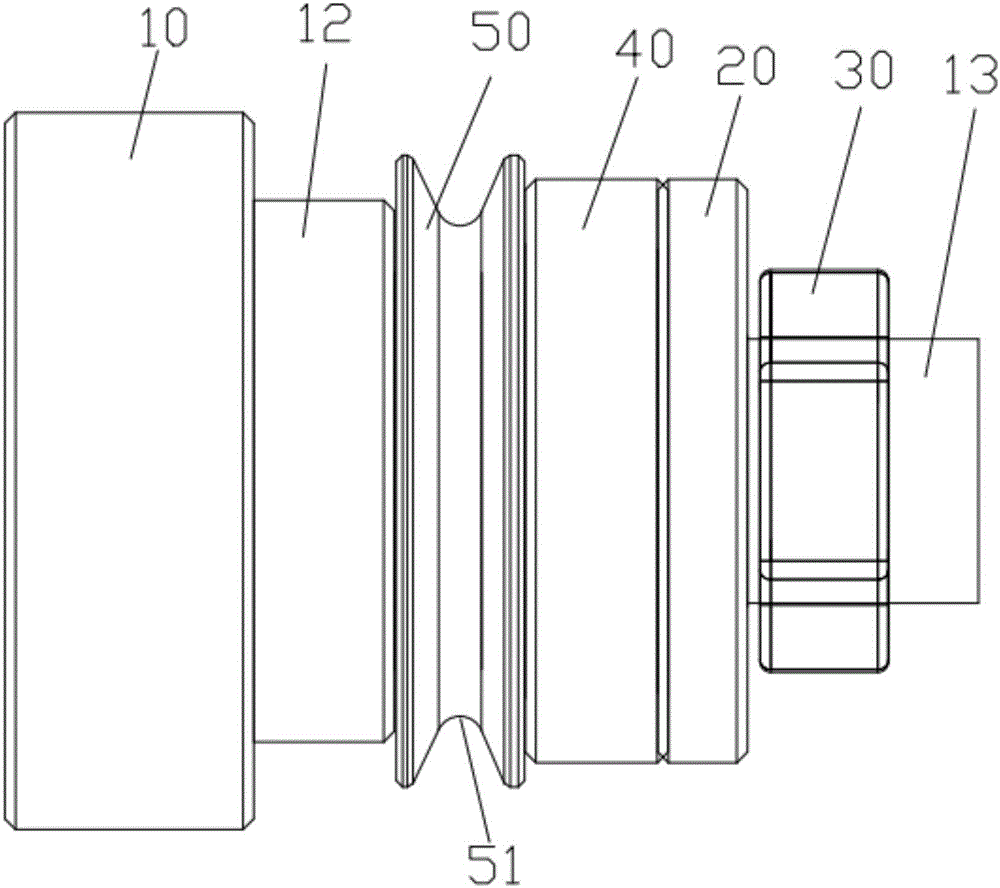

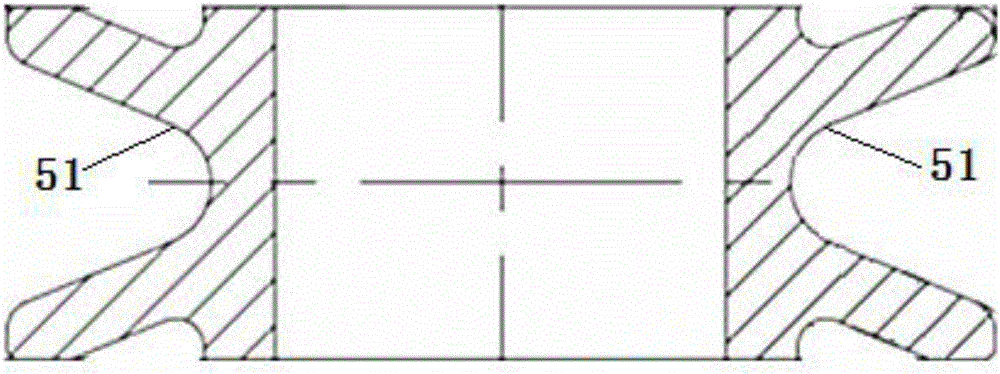

[0013] See figure 1 , figure 2 The embodiment of the present invention provides a clamping and positioning device for V-groove machining of pulley parts, which includes a fixed mandrel assembly 10, a movable pressing plate assembly 20, and a locking member 30.

[0014] The fixed mandrel assembly 10 includes a fixed seat 11, a plurality of cylindrical carcasses 12, and a mandrel 13 which are fixedly connected coaxially and concentrically in sequence. The diameters of the plurality of cylindrical carcasses 12 are from a direction close to the fixed seat 11 to a direction close to the mandrel 13 The directio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com