Circular glass cutting device

A glass cutting and circular technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve the problem of waste of raw materials, and achieve the effect of preventing glass damage and increasing the margin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

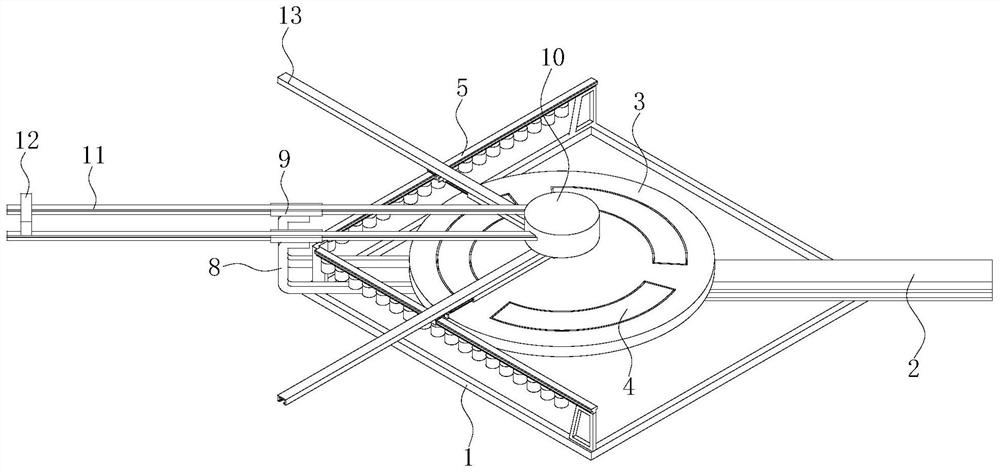

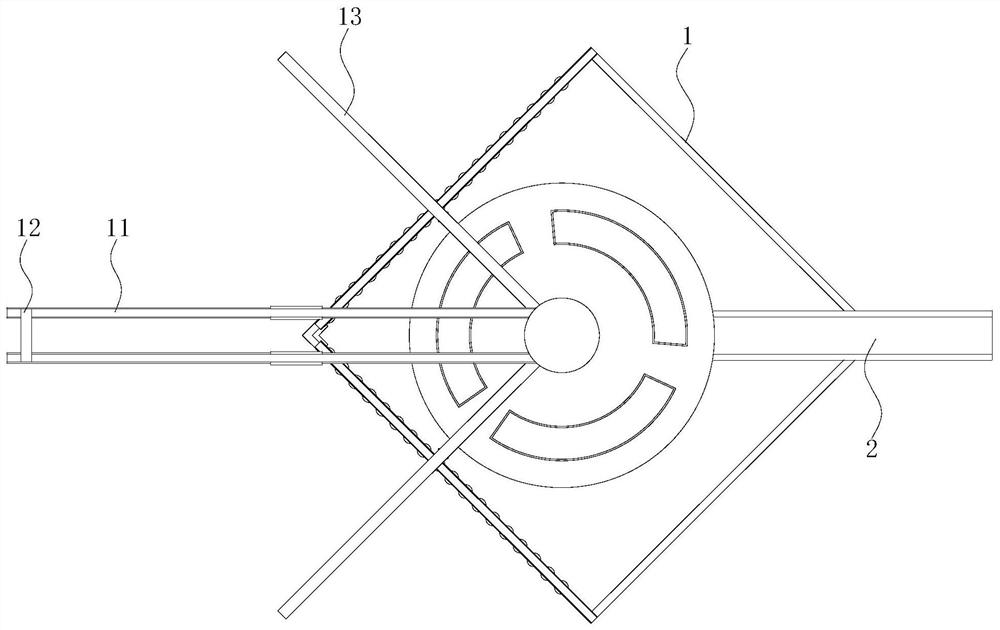

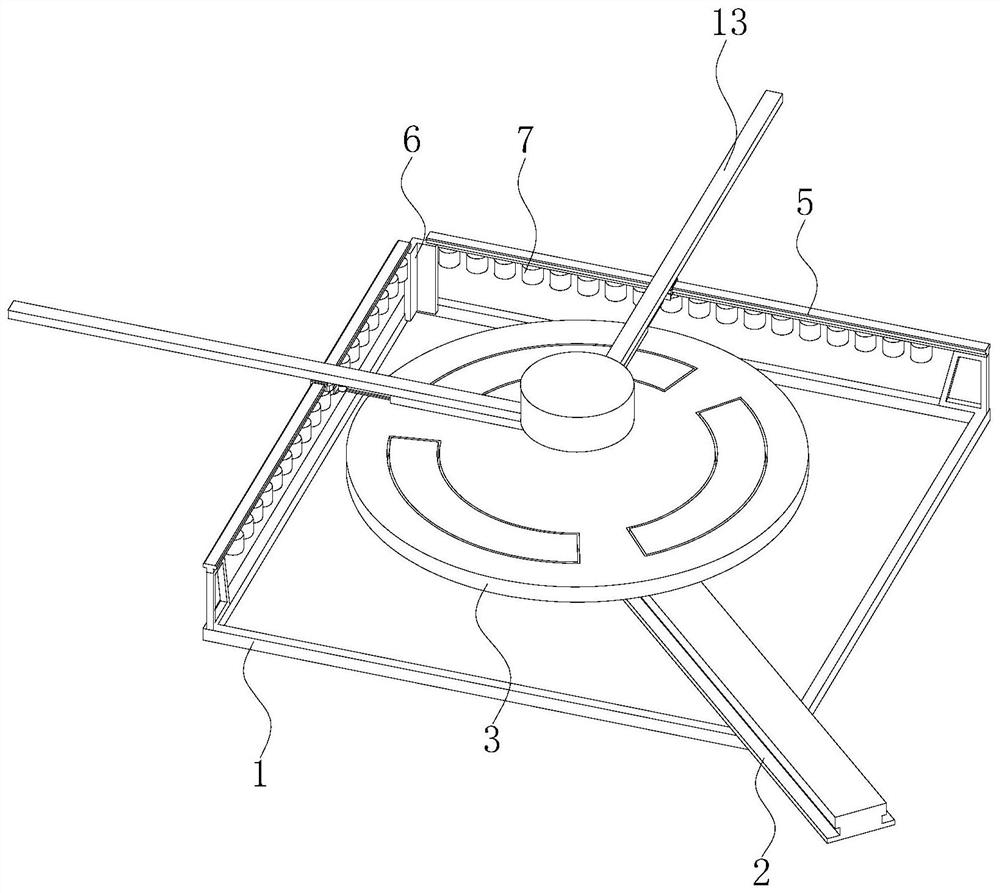

[0023] like Figure 1-6 As shown, a circular glass cutting device includes a base 1, a guide rail 2 is fixedly installed above the base 1, and the guide rail 2 is located diagonally from the upper left corner to the lower right corner of the base 1, and a supporting plate is slidably installed above the guide rail 2 3. A lifting mechanism 4 is installed inside the supporting plate 3, and the lifting mechanism 4 can lift the entire glass by electric control. There are two limit rods 5 above the base 1, and the two limit rods 5 are respectively located at the bottom of the base 1. The left end and upper end of the upper surface, the base 1 is a square structure, and the two limit rods 5 are vertically arranged. The distance between the two limit rods 5 and the upper left corner of the base 1 is the same, and the left ends of the two limit rods 5 pass through Right-angle plate 6 is fixedly connected, and the lower end of right-angle plate 6 is fixedly connected with the upper lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com