A tubular injection molding die, production device and production process

A technology for producing devices and forming molds, which can be applied to tubular items, household appliances, other household appliances, etc., and can solve the problems of low collection efficiency and low safety factor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

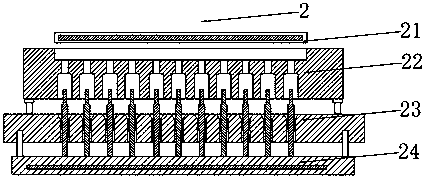

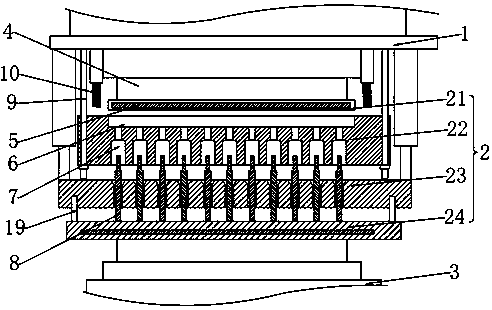

[0032] Such as figure 1 As shown, the tubular injection molding mold 2 of Embodiment 1 includes an upper template 21, a first middle template 22, a second middle template 23 and a lower template 24 from top to bottom, and a heating Mechanism 5; the top surface of the first middle template 22 is provided with a recessed part 6 that matches the bottom surface of the upper template 21, and the first middle template 22 and the second middle template 23 below the recessed part 6 are provided with a one-to-one corresponding rubber flow Road through holes 7, the lower template 24 is provided with insert pins 8 corresponding to the rubber flow channel through holes one by one. The setting pin 8 is a variable diameter setting pin.

[0033] Such as figure 2 As shown, the tubular injection part production device in embodiment 1 includes an upper mold base 1, a forming mold 2 and a lower mold base 3, and the upper mold plate 21 and the upper mold base 1, the lower mold plate 24 and the...

Embodiment 2

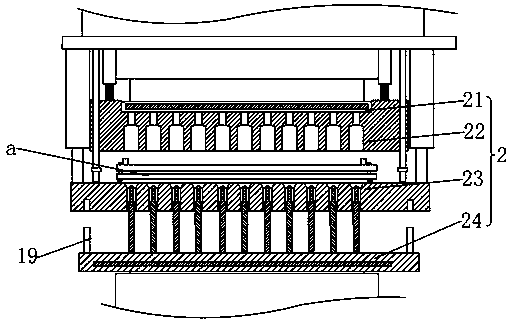

[0037] Such as Figure 3-5 As shown, the difference between embodiment 2 and embodiment 1 is that the production device of embodiment 2 also includes a clamping mechanism a, and the clamping mechanism includes a first orifice plate 11 and a second orifice plate 12, and the first orifice plate 11 and the second orifice plate The matching holes of the injection parts on the second orifice plate 12 are provided in one-to-one correspondence, and the surface of the second orifice plate 12 is provided with vertical bosses, which are connected with the strip holes 13 on the first orifice plate 11 in clearance fit, and the bosses A stop nut 14 is arranged at the free end of the first orifice plate 11 and a micro-motion mechanism is arranged between the first orifice plate 11 and the second orifice plate 12, and the micro-motion mechanism drives the first orifice plate to move along the long side direction of the strip hole.

[0038] In Embodiment 2, the micro-motion mechanism includes...

Embodiment 3

[0040] Such as Figure 6 As shown, the difference between embodiment 3 and embodiment 2 is that the micro-motion mechanism is a linear cylinder 18 that is axially consistent with the long side of the strip hole, the piston of the linear cylinder 18 is fixedly connected with the first orifice plate, and the cylinder of the linear cylinder 18 The body is fixedly connected with the second orifice plate.

[0041] In order to maintain the balance of the clamping mechanism, the micro-motion cylinder can be arranged symmetrically. Micro cylinders can be used in actual use.

[0042]The diameter of the rubber runner through hole on the top surface of the second middle template 23 is larger than the diameter of the rubber runner through hole 7 on the bottom surface of the second middle template 23 .

[0043] Before molding, first spray silicone oil on the top depression of the first middle template and the surface of the insert pin, then place the raw material in the top depression of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com