A post-finishing process of waterproof, oil-proof and antifouling fabric

An anti-fouling fabric, waterproof and oil-proof technology, applied in the textile field, can solve the problems of improving the three-proof performance of the fabric, cumbersome finishing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

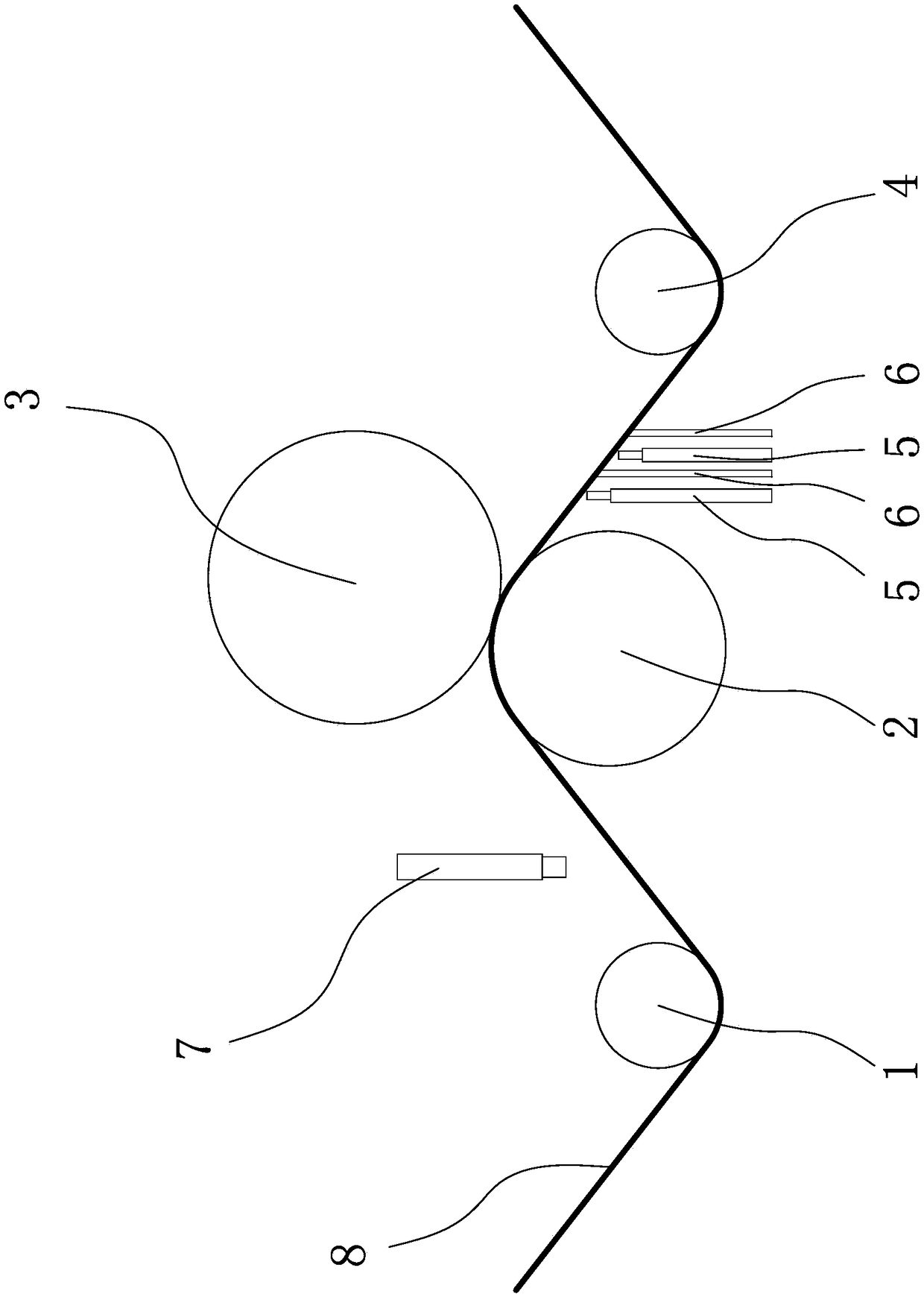

Image

Examples

Embodiment 1

[0028] The post-finishing process of the waterproof, oil-proof and antifouling fabric consists of the following steps:

[0029] 1) Dyeing: Add dyeing acid and pro-fiber leveling agent in sequence below 35°C in the dyeing cylinder, stir evenly, add dye and carry out secondary stirring, then heat up to 60°C at a rate of 1°C / min, then change to Raise the temperature to 150°C at a rate of 3°C / min and keep it warm for 80 minutes, and then lower it to 50°C at a rate of 2°C / min after the end of the hold;

[0030] 2), one-time washing: take out the fabric in the dyeing cylinder and put it into the first washing tank for washing. The water temperature in the first washing tank is 50°C;

[0031] 3) Secondary washing: take the fabric out of the first washing tank and put it into the second washing tank for washing. The water temperature of the second washing tank is 30°C, and soda ash and sodium dithionite are added in the second washing tank;

[0032] 4) Washing three times: take the f...

Embodiment 2

[0040] The post-finishing process of the waterproof, oil-proof and antifouling fabric consists of the following steps:

[0041] 1) Dyeing: Add dyeing acid and pro-fiber leveling agent in sequence below 35°C in the dyeing cylinder, stir evenly, add dye and carry out secondary stirring, then heat up to 70°C at a rate of 1°C / min, then change to Raise the temperature to 150°C at a rate of 2°C / min and keep it warm for 70 minutes, and then lower it to 60°C at a rate of 2°C / min after the end of the hold;

[0042] 2), one-time washing: take out the fabric in the dyeing cylinder and put it into the first washing tank for washing. The water temperature in the first washing tank is 60°C;

[0043] 3) Secondary washing: Take the fabric out of the first washing tank and put it into the second washing tank for washing. The water temperature of the second washing tank is 35°C, and soda ash and sodium dithionite are added in the second washing tank;

[0044] 4) Washing three times: take the f...

Embodiment 3

[0052] The post-finishing process of the waterproof, oil-proof and antifouling fabric consists of the following steps:

[0053] 1) Dyeing: Add dyeing acid and pro-fiber leveling agent in sequence below 35°C in the dyeing cylinder, stir evenly, add dye and carry out secondary stirring, then heat up to 65°C at a rate of 1°C / min, then change to Raise the temperature to 150°C at a rate of 2°C / min and keep it warm for 75 minutes. After the hold is over, lower it to 55°C at a rate of 2°C / min;

[0054] 2), one-time washing: take out the fabric in the dyeing cylinder and put it into the first washing tank for washing. The water temperature in the first washing tank is 55°C;

[0055]3) Secondary washing: take the fabric out of the first washing tank and put it into the second washing tank for washing. The water temperature of the second washing tank is 33°C, and soda ash and sodium dithionite are added in the second washing tank;

[0056] 4) Washing three times: take the fabric out of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com