Aircraft ignition cable assembling method

An assembly method and cable technology, applied to circuits, auxiliary devices, electrical components, etc., can solve problems such as reduced product reliability, failure to pass tests, time-consuming and laborious cleaning, etc., to achieve improved product reliability, good three-proof performance, and three-dimensional protection. Anti-performance high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for assembling an aircraft ignition cable mainly comprises the following steps:

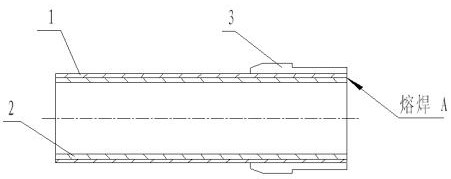

[0026] Step S100: if figure 1 As shown, the first connection sleeve 3 is placed outside the end of the metal hose, and the end is welded for the first time to obtain a hose assembly;

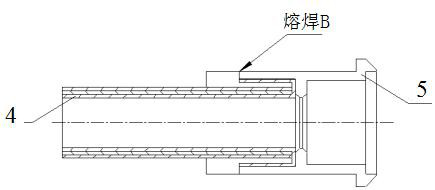

[0027] Step S200: if figure 2 As shown, the copper braided sleeve 4 passes through the hose assembly and is turned outward at the end of the hose assembly; a second connecting sleeve 5 is sheathed outside the end of the hose assembly, and the first connecting sleeve 3 and the second Copper braided sleeves 4 are arranged between the connecting sleeves 5, and the connection between the three is welded for the second time.

[0028] The invention decomposes the original assembling and welding process into two parts, decomposes the original one metal part into two parts, and improves the original brazing process into two welding formings. The invention has strong practicability and solves the proble...

Embodiment 2

[0030] This embodiment is optimized on the basis of Embodiment 1. In the step S100, the first fusion welding is performed on the plane of the end of the metal hose sleeved with the first connecting sleeve 3 .

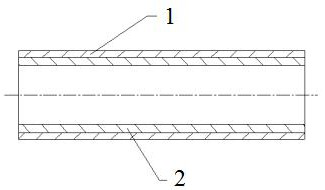

[0031] Further, as figure 1 , image 3 As shown, the metal hose includes a stainless steel bellows 2 and a stainless steel wire braided sleeve 1 that are sheathed in sequence from the inside to the outside; the outer end of the stainless steel wire braided sleeve 1 is covered with a first connecting sleeve 3 .

[0032] Further, the copper braided sheath 4 is snugly sleeved inside the hose assembly.

[0033] Other parts of this embodiment are the same as those of Embodiment 1, so details are not repeated here.

Embodiment 3

[0035] This embodiment is optimized on the basis of Embodiment 1 or 2. In the step S200, the first connection sleeve 3 is provided with a receiving limit platform, and the second connection sleeve 5 is correspondingly provided with an abutment surface, so One end of the braided braided sleeve 4 is turned outward and fitted along the length direction of the first connecting sleeve 3 , and the abutting surface is fixedly connected with the receiving limit platform.

[0036] Further, the second welding is performed on the receiving limit platform and the abutment surface.

[0037] The invention decomposes the original assembling and welding process into two parts, decomposes the original one metal part into two parts, and improves the original brazing process into two welding formings. The invention has strong practicability and solves the problem that the existing assembly structure cannot satisfy the three-proof performance of the product. At the same time, the structural stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com