Prestress anti-offset reinforcement structure applied to wooden frame and construction method of prestress anti-offset reinforcement structure

A prestressed, wood structure technology, applied in building construction, building maintenance, construction, etc., can solve problems such as inability to use, high cost, damage to buildings, etc., and achieve the effect of improving overall rigidity, simple and convenient operation, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the above-mentioned features and advantages of the present invention more comprehensible, the following specific embodiments are described in detail with reference to the accompanying drawings.

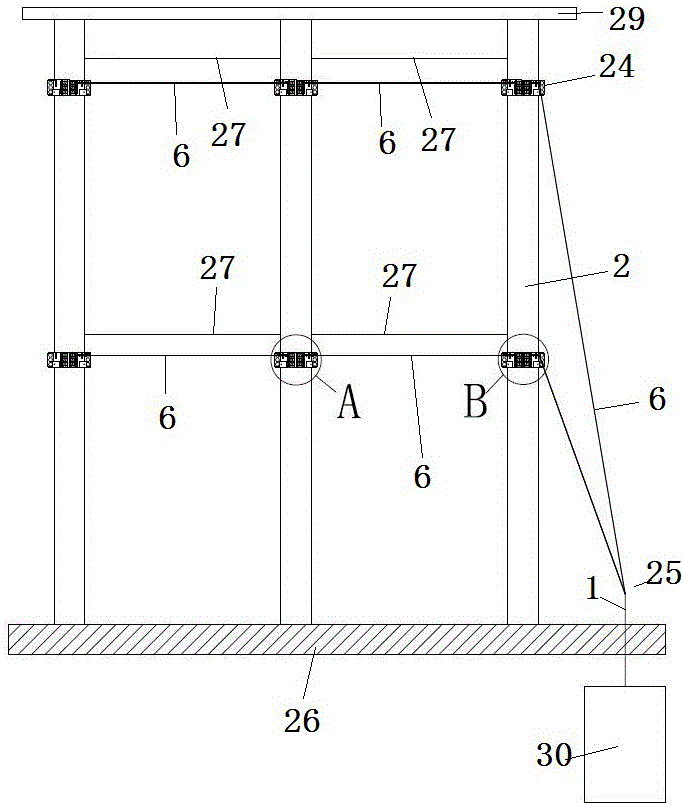

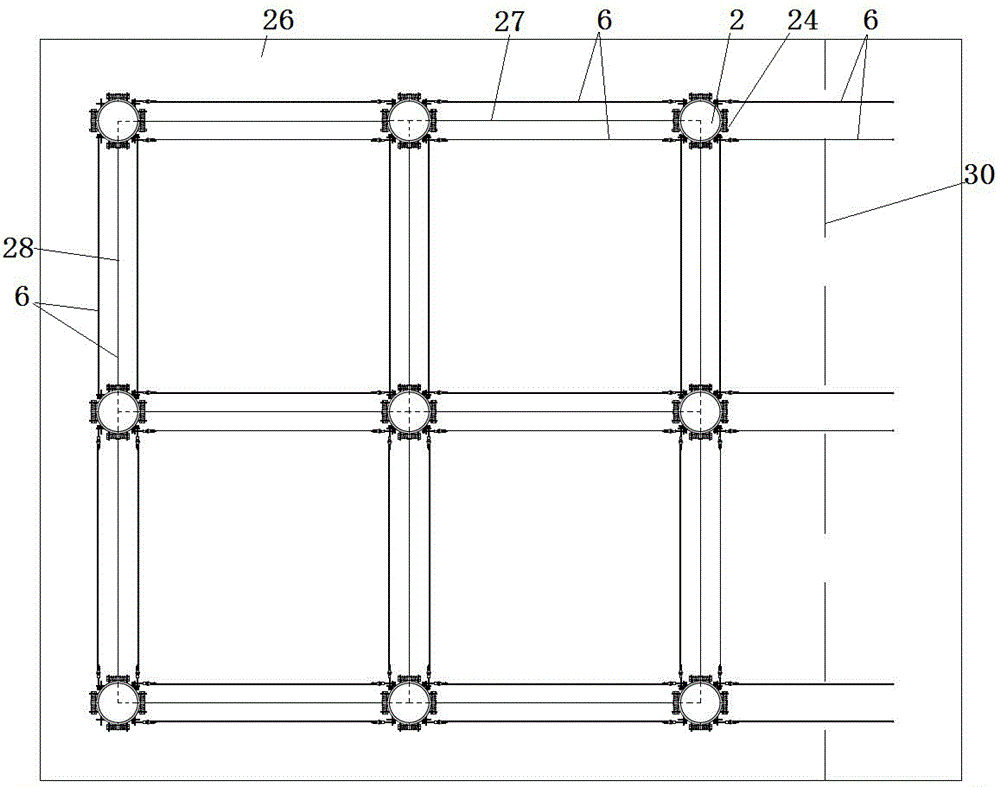

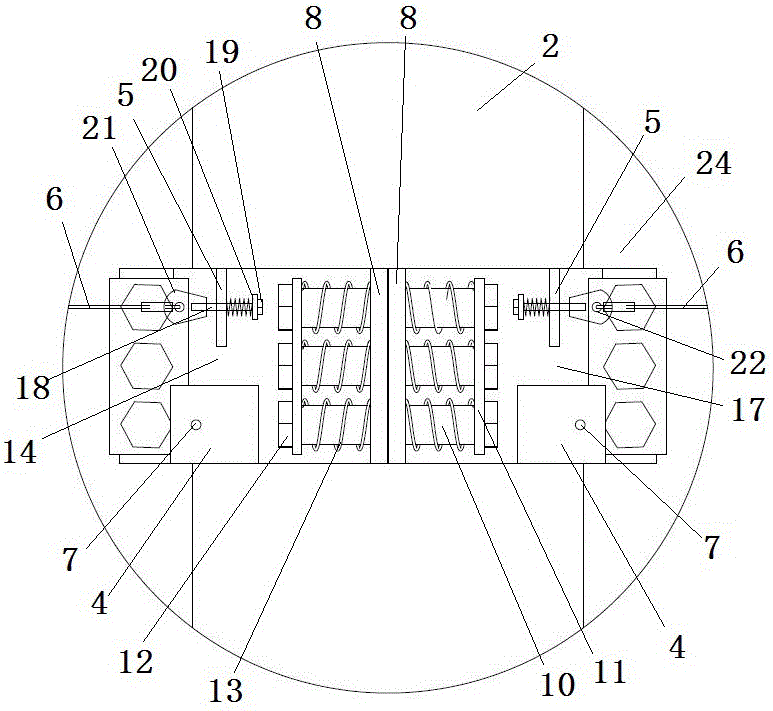

[0037] Such as Figure 1~11As shown, a prestressed fixed deflection structure applied to a wooden frame includes several pillars 2 supported on the building ground 26, a plurality of pillars form a support frame, and each pillar is provided with a hoop 24, two The hoops on adjacent columns are all tensioned with each other by prestressed steel wires 6 , and the support frame is connected to the external fixed end 25 by prestressed steel wires on at least one outer hoop.

[0038] In the embodiment of the present invention, several pillars are distributed on the ground in an array, and several beams 27 and longitudinal beams 28 are fixed between two adjacent pillars to form a support frame with several rows and several columns.

[0039] In the embodiment of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com