Electric heating type catalytic converter and heating control method thereof

A catalytic converter, electric heating technology, applied in the electronic control of exhaust treatment devices, machines/engines, exhaust gas treatment, etc., can solve the problems of high concentration of harmful gases, low catalyst purification efficiency, limited effect, etc. The effect of reducing vehicle emissions, shortening light-off time, and preventing electric leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific implementation manner of the present invention will be described in further detail below by describing the best embodiment with reference to the accompanying drawings.

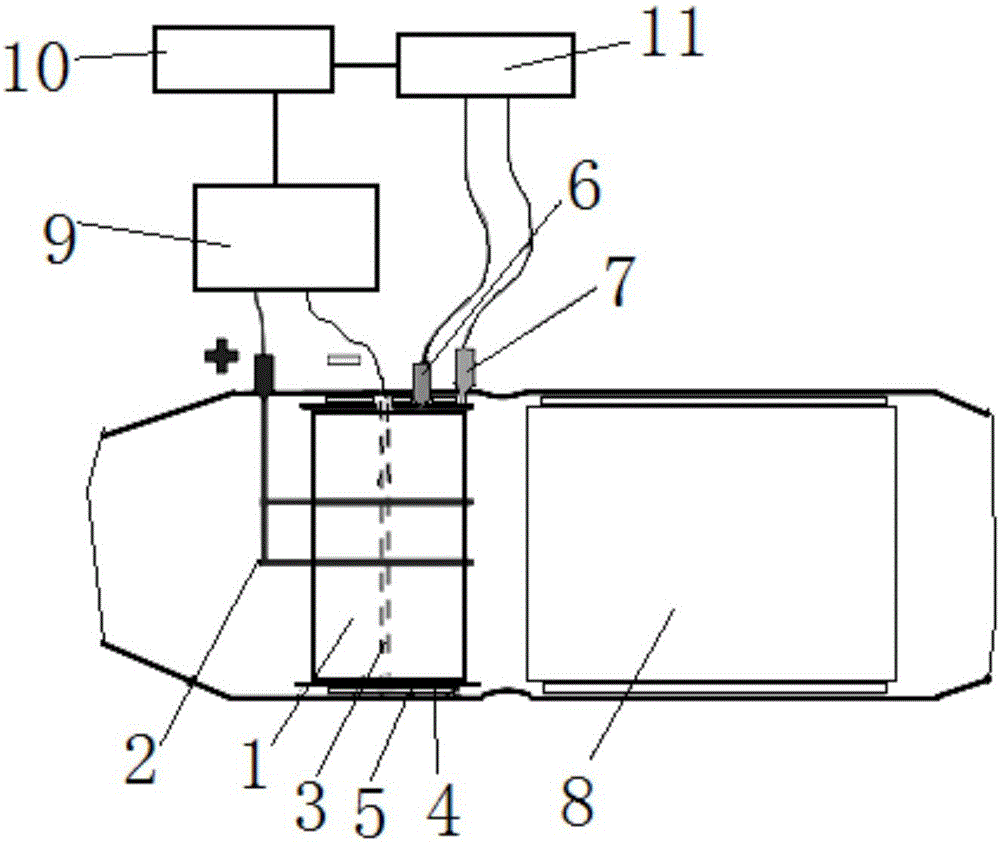

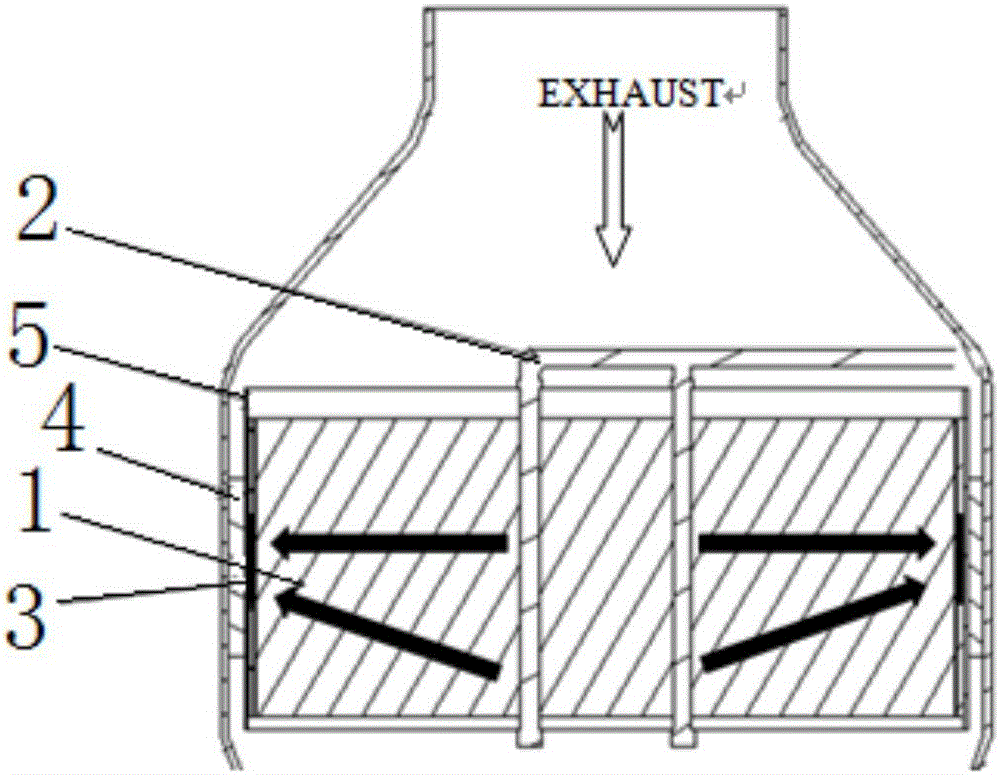

[0028] like figure 1 and figure 2 As shown, this kind of electric heating catalytic converter includes a housing, and a metal carrier 1 is arranged in the housing, and a positive electrode 2 and a negative electrode 3 connected to a power supply 10 are arranged on the metal carrier 1; the outer surface of the metal carrier 1 is provided with The temperature sensor 6, the metal carrier 1 is provided with an insulating structure wrapping the side of the metal carrier 1 and the temperature sensor 6; the outer wall of the housing is provided with a leakage sensor 7; the power supply 10, the temperature sensor 6 and the leakage sensor 7 are all connected to the ECU11. The center of the metal carrier 1 is used as the positive electrode, and the outer wall of the carrier is used as the negative ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com