Test method of connection reliability of battery system

A battery system and testing method technology, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of fast and effective detection of connection failures of power circuits that cannot be realized, so as to ensure safety and reliability, and improve safety. performance, and the effect of improving evaluation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The test method for the battery system connection reliability of embodiment 1 includes the following steps:

[0036] 1) Under static conditions, use test instruments to measure the AC resistance of each battery pack in the battery system, and compare them with the corresponding qualification standards;

[0037] If the AC internal resistance meets the qualified standard, proceed to step 2);

[0038] If the AC internal resistance exceeds the qualified standard, it indicates that the connection of the battery pack is abnormal;

[0039] 2) Under 50% SOC, use the current I to discharge or charge the battery system for 1 minute, and check the maximum voltage difference of the battery pack, which is recorded as ΔU;

[0040] If the pressure difference meets the qualified standard, indicating that the connection reliability of the battery pack is normal, proceed to step 3);

[0041] If the pressure difference exceeds the qualified standard, it indicates that the connection of ...

experiment example

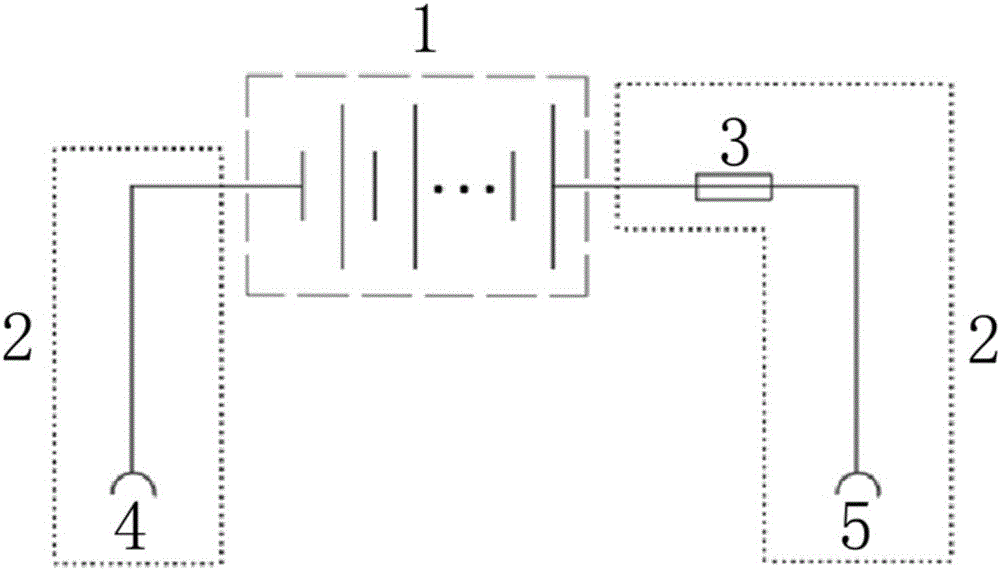

[0070] In this experimental example, the power system of the above-mentioned battery system connection reliability test method is used for testing, including the following contents:

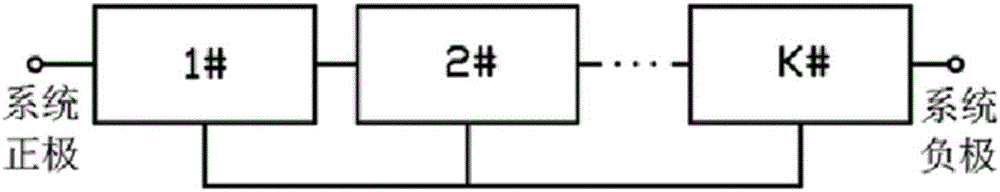

[0071] The measured power system consists of 2 parallel 36 series of 200Ah lithium iron phosphate batteries, including 3 battery boxes. The AC internal resistance of the battery pack, the voltage difference ΔU of the battery pack, and the DC internal resistance DCR of the electrical circuit are given below for the three test systems 电气回路 The actual measurement data, the judgment standard, the judgment result and the determination method of the qualification standard of the three indicators.

[0072] The test results of the three test systems are shown in Table 2.

[0073] Table 2 Test results of three sets of test systems

[0074]

[0075]

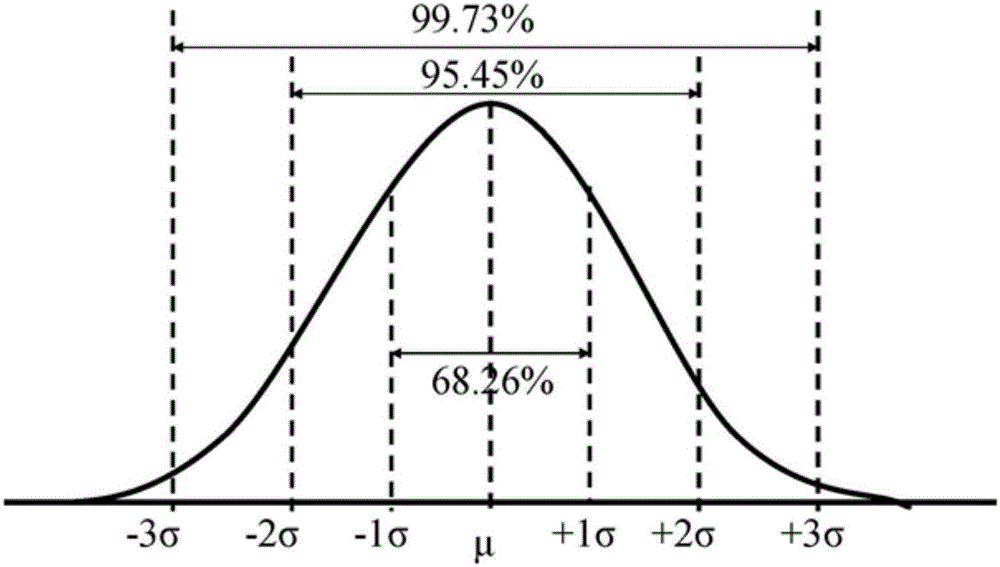

[0076] In the test method for the reliability of the connection of the battery system mentioned above, the determination method for the qualification...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com