Acidification mechanism for battery acidification

A technology for acid use and acid addition, applied in battery pack parts, circuits, electrical components, etc., can solve the problems of inaccurate coordination between acid addition mechanism and conveying mechanism, reduction of processing efficiency and effect, and unreasonable design of acid addition mechanism. , to achieve the effect of improving processing efficiency and stability, easy to add acid position, and improving mobile stability and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

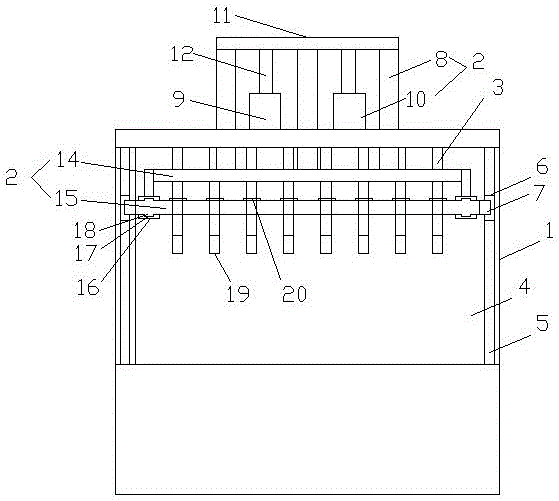

[0015] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0016] An acid-adding mechanism for acid-adding batteries, including a casing, a lifting mechanism and several acid injection pipes, wherein, an acid-adding chamber is arranged inside the casing, slide rails are arranged on both sides of the acid-adding chamber, and the sliding rails A telescopic cylinder is arranged on the rail, and a telescopic rod is arranged on the telescopic cylinder. The lifting mechanism includes several guide columns, a first lifting cylinder and a second lifting cylinder. Several guide columns are evenly spaced, and a connecting plate is provided on the top , the first lifting cylinder and the second lifting cylinder are provided with lifting rods, and the tops of the lifting rods are vertically connected with the connecting plate;

[0017] The bottom of the guide column passes through the casing to the acid adding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com