Multi-function automatic tool for electric insurance maintenance

An automatic tool and multi-functional technology, applied in the direction of overhead line/cable equipment, etc., can solve the problems of reducing work efficiency, increasing safety hazards, cumbersome replacement operations, etc., to improve work efficiency, improve safety and work efficiency, and multi-function Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

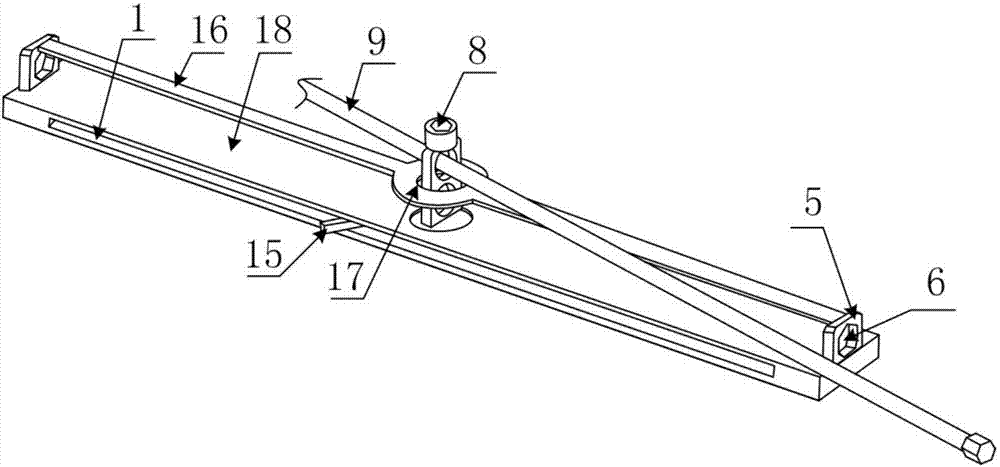

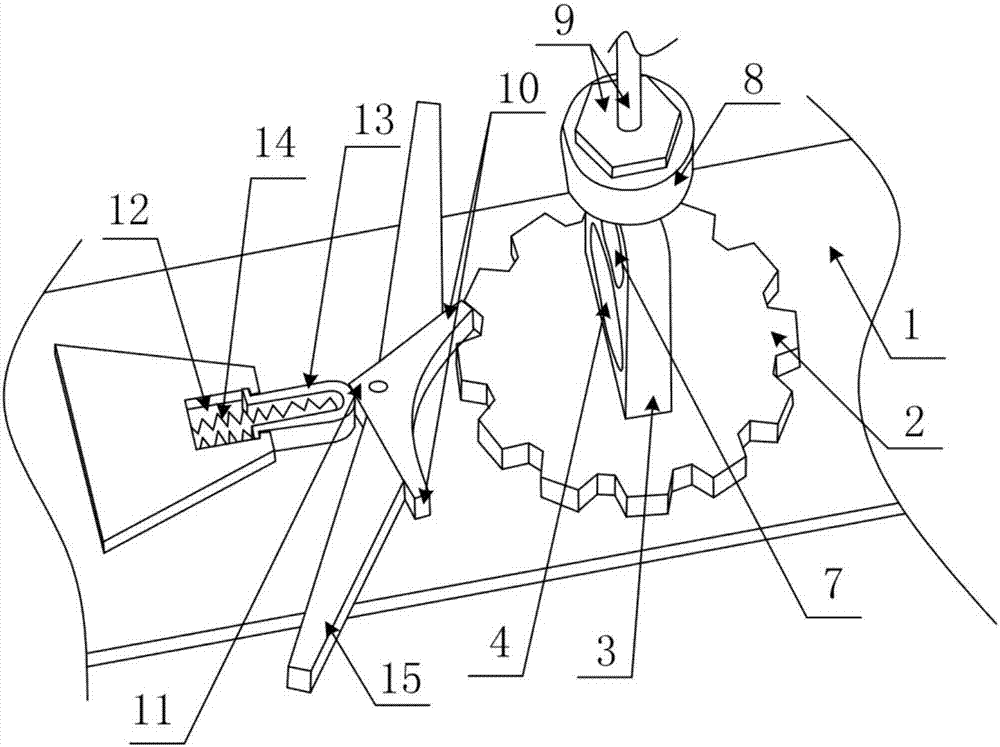

[0029] Multifunctional power insurance maintenance automatic tools, such as figure 1 with figure 2 As shown, it includes the base plate 1, the gear 2 fixed above the base plate 1 through the first rotating shaft, the rotating handle 3 arranged on the gear 2, the rope hole 4 arranged on the rotating handle 3, and the gears fixed on both sides of the gear 2 respectively. The thread passing plate 5 on the bottom plate 1 is arranged on the hexagonal bolt hole 6 on the thread passing plate 5 , and the limiting device for limiting the rotation direction of the gear 2 is arranged on the bottom plate 1 .

[0030] In order to facilitate operation, the bottom end of the rotating handle 3 is fixedly connected with the gear 2, the rotating handle 3 is also provided with an operating hole 7 above the rope hole 4, and the top of the rotating handle 3 is also provided with a screw operating rod interface 8; The screw operating rod interface 8 is provided with a screw operating rod 9 . The...

Embodiment 2

[0035] The difference between this embodiment and Embodiment 1 is that this embodiment increases the structure of the connecting rod 16 and the tool upper cover 18, and the specific settings are as follows:

[0036] Such as figure 1 As shown, the top ends of the wire passing boards 5 on both sides of the gear 2 are connected by a connecting rod 16, and the connecting rod 16 above the gear 2 is also provided with a positioning hole 17. A tool upper cover 18 for covering the limit device and the gear 2 is also arranged between the connecting rod 16 and the bottom plate 1 .

Embodiment 3

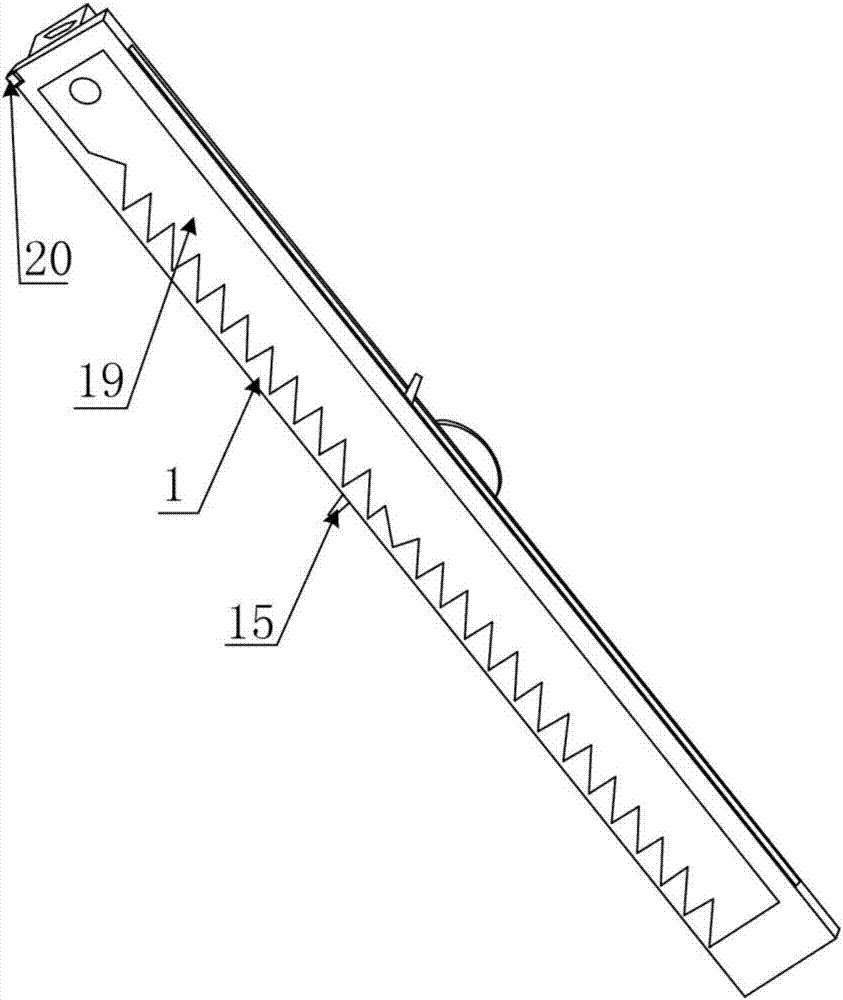

[0038] The difference between this embodiment and Embodiment 1 is that this embodiment increases the function of the cutter, and the specific settings are as follows:

[0039] The bottom of the base plate 1 is also hinged with a cutter 19 through the third rotating shaft, and the bottom of the base plate 1 is also provided with a stop nail 20 that limits the position of the cutter 19, such as image 3 with Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com