High axial bearing stepping linear motor

A linear motor, axial technology, applied in the direction of electrical components, electromechanical devices, propulsion systems, etc., can solve the problems of motor power density reduction, long axial space, etc., achieve small axial play and clearance, and improve linear positioning accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

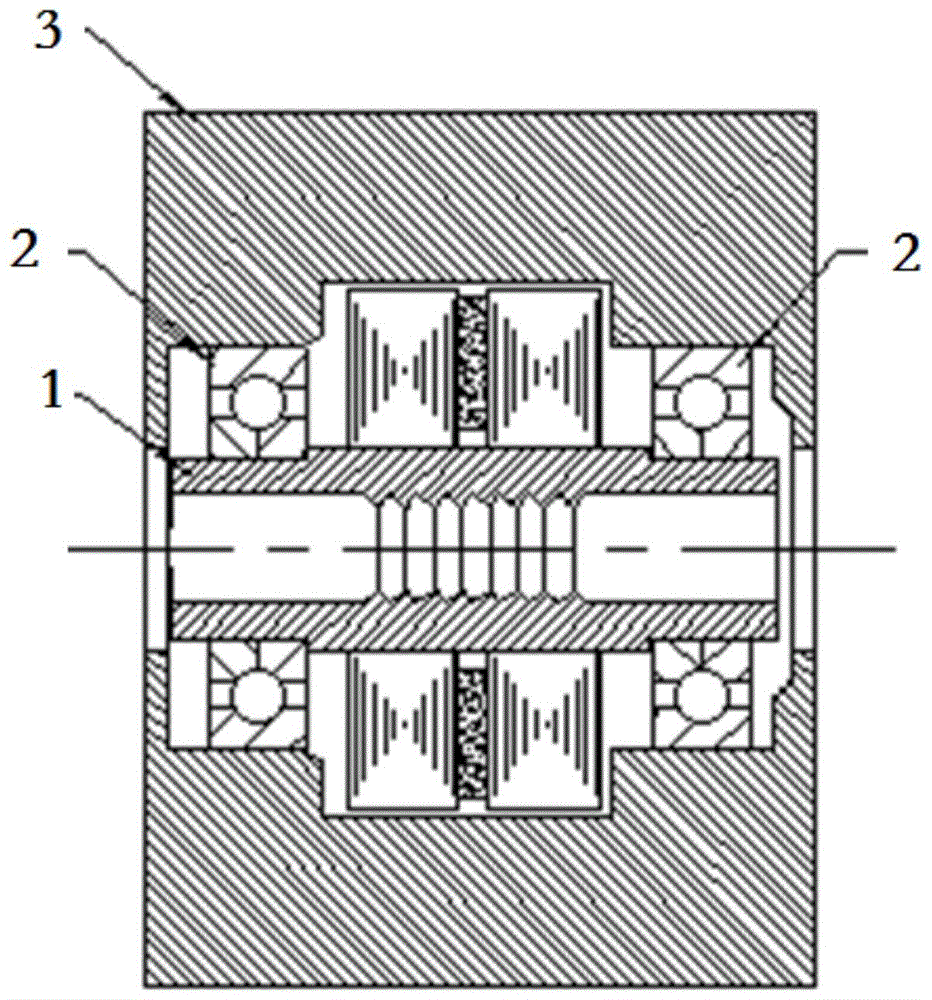

[0030] Such as figure 1 As shown, the high axial load stepping linear motor includes: rotor 1 with nut; four-point angular contact bearing 2 (also known as four-point contact ball bearing), installed at both ends of the rotor; stator 3, set opposite to the rotor .

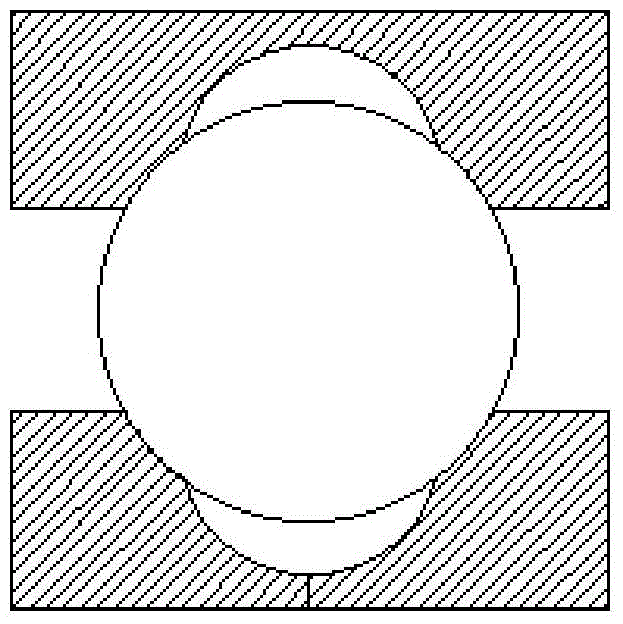

[0031] The four-point angular contact bearing 2 is provided with one, two or four. The four-point angular contact bearing 2 includes an outer ring, an inner ring and balls, the outer ring is arranged outside the inner ring, and the balls are installed between the outer ring and the inner ring.

[0032] Both the outer ring and the inner ring are provided with arc-shaped raceways for ball rolling. The four-point angular contact bearing is a single-groove quadrangular contact bearing, a double raceway angular contact bearing or an outer groove quadrangular contact bearing.

Embodiment 2

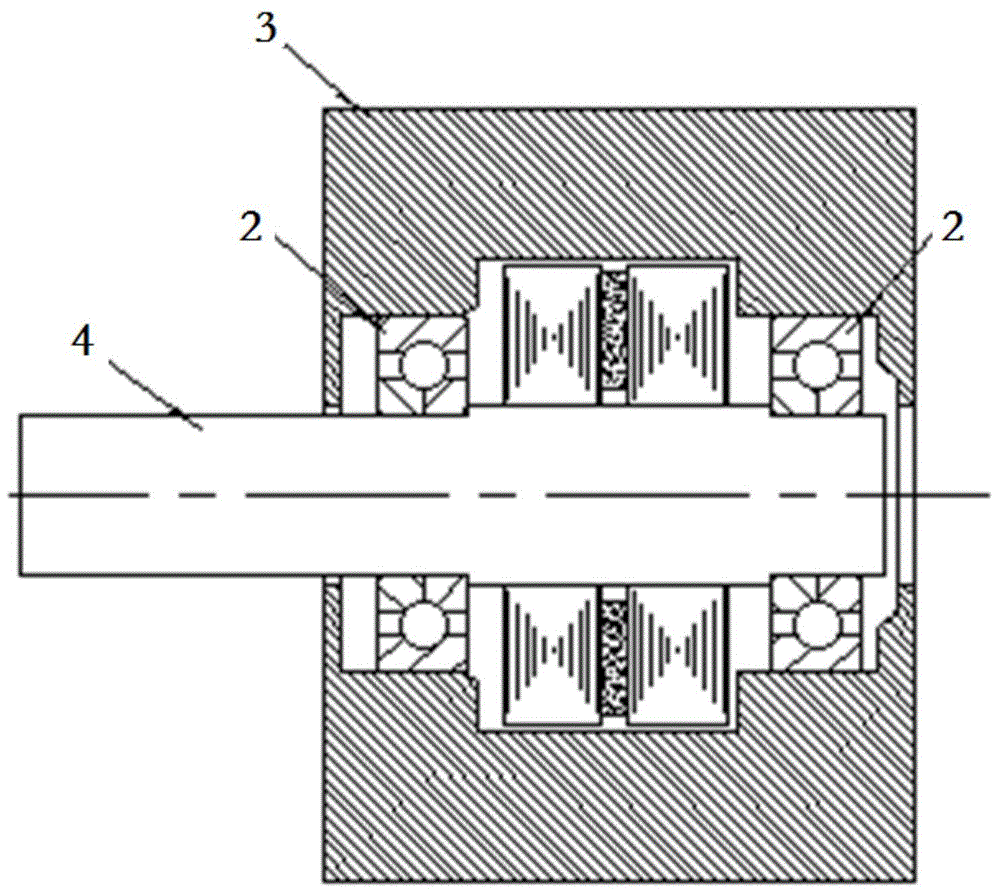

[0034] Such as figure 2 As shown, the rotor is the rotor 4 with a screw, and the rest are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com