Straight beam buckling electrostatic type micro mechanical optical switch

A micro-mechanical and electrostatic technology, applied in the direction of optics, optical components, optical waveguide coupling, etc., can solve the problems of device stability and reliability, heat can not be effectively dissipated, shorten the service life of devices, etc., to reduce the Effect of driving voltage and deformation time, simple structure, and improved reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

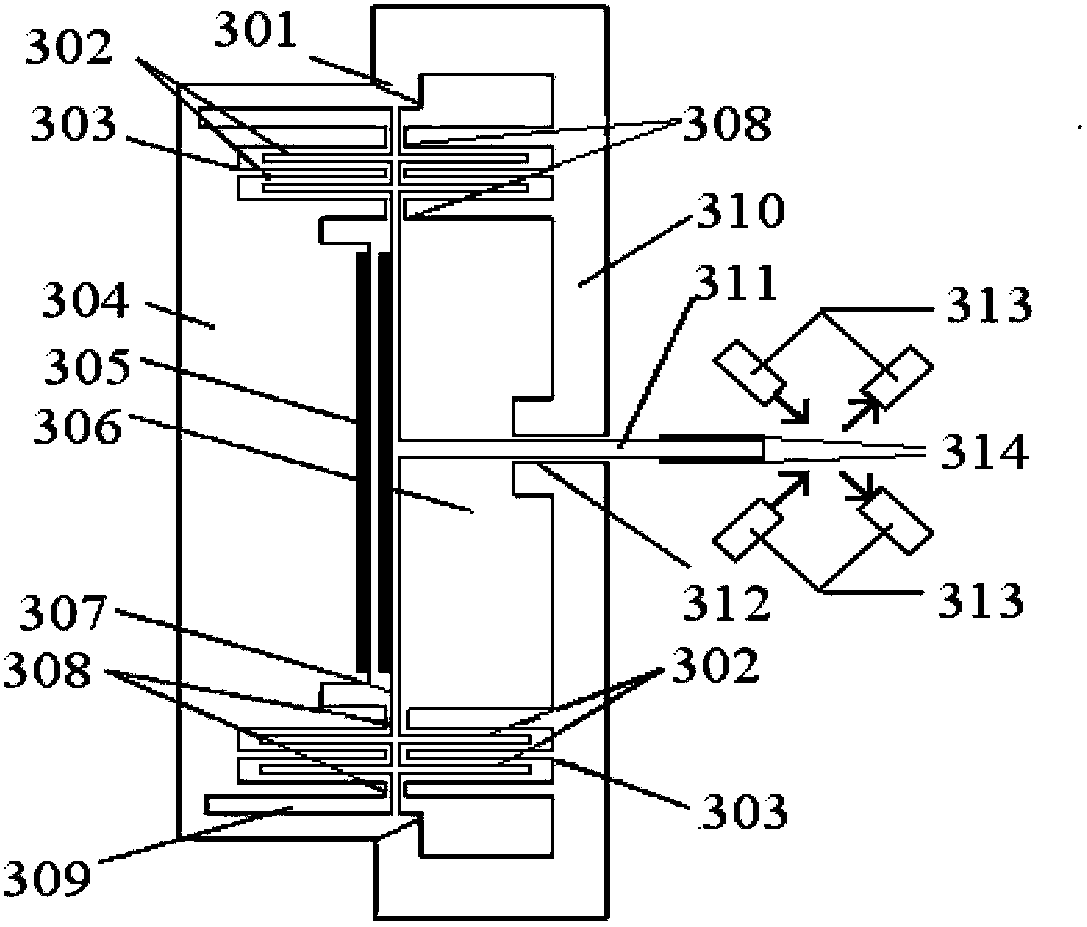

[0036] refer to image 3 , the straight beam buckling electrostatic micromechanical optical switch of the present invention is mainly composed of micro beam 307, fixed base 304, outer frame 310, guide mechanism 308, drive electrode pair 305, 306, adjustment electrode pair 302, 303, guide groove 312, micro The mirror bracket 311, the micro mirror 314 and the optical fiber 313 are composed. Wherein the optical fiber 313 is vertically intersected to form an optical path, the middle position of the microbeam 307 is a rhombus structure, two guide mechanisms 308 are provided, which are respectively located at the upper and lower ends of the fixed base 304, and the micromirror holder 311 is a square cylinder structure.

[0037] The microbeam 307 is integrated with the fixed base 304, and a span support structure 309 is used at the connection position of the two to increase the axial load on the microbeam 307 to reduce the driving voltage and shorten the switch response. time. The mic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com