Cutter head for a meat cutter

A meat grinder and knife head technology, applied in the system field, can solve the problems of unhygienic knife head, etc., achieve the effect of simplifying transportation, simplifying logistics work, and avoiding abnormal work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

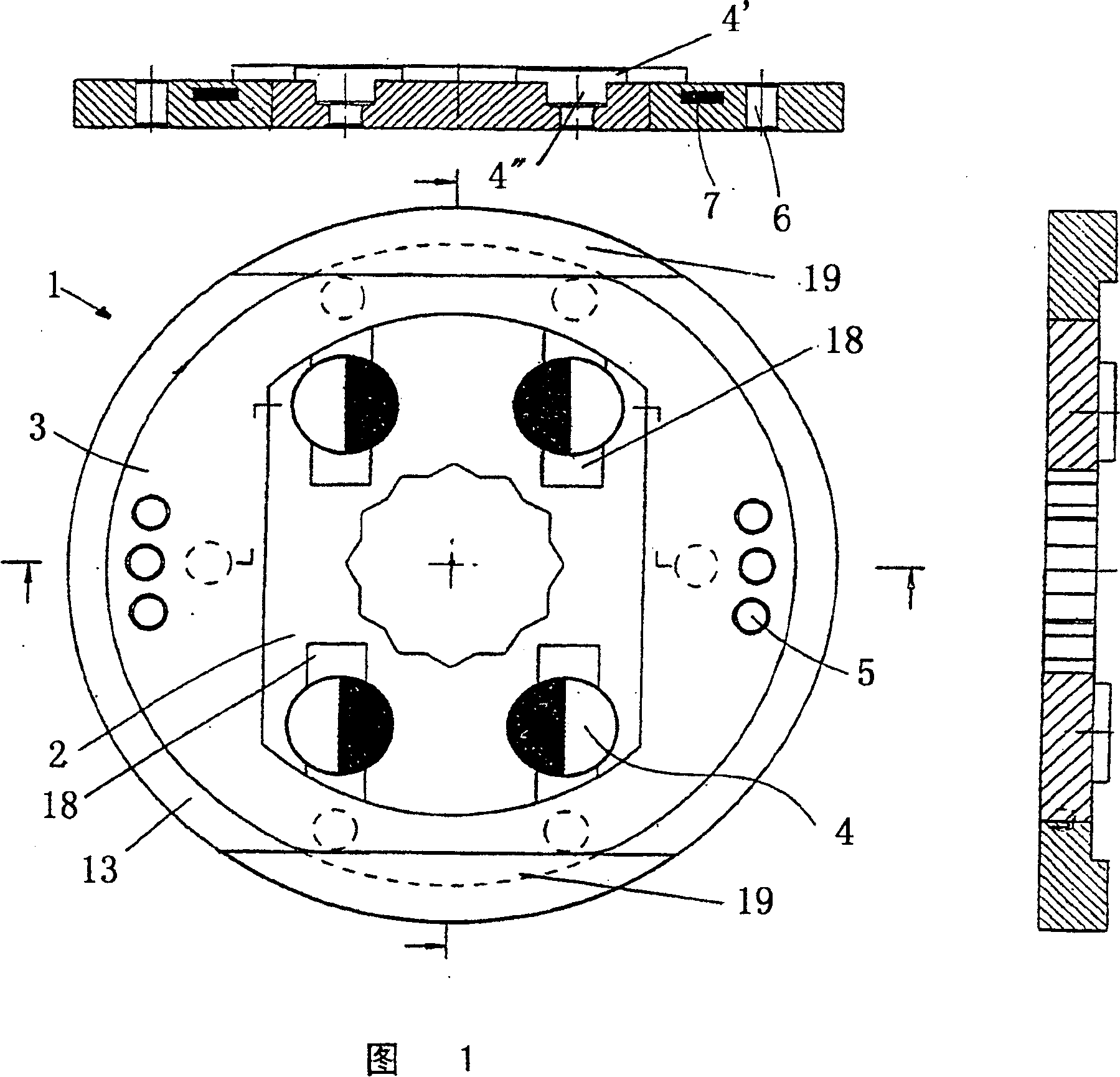

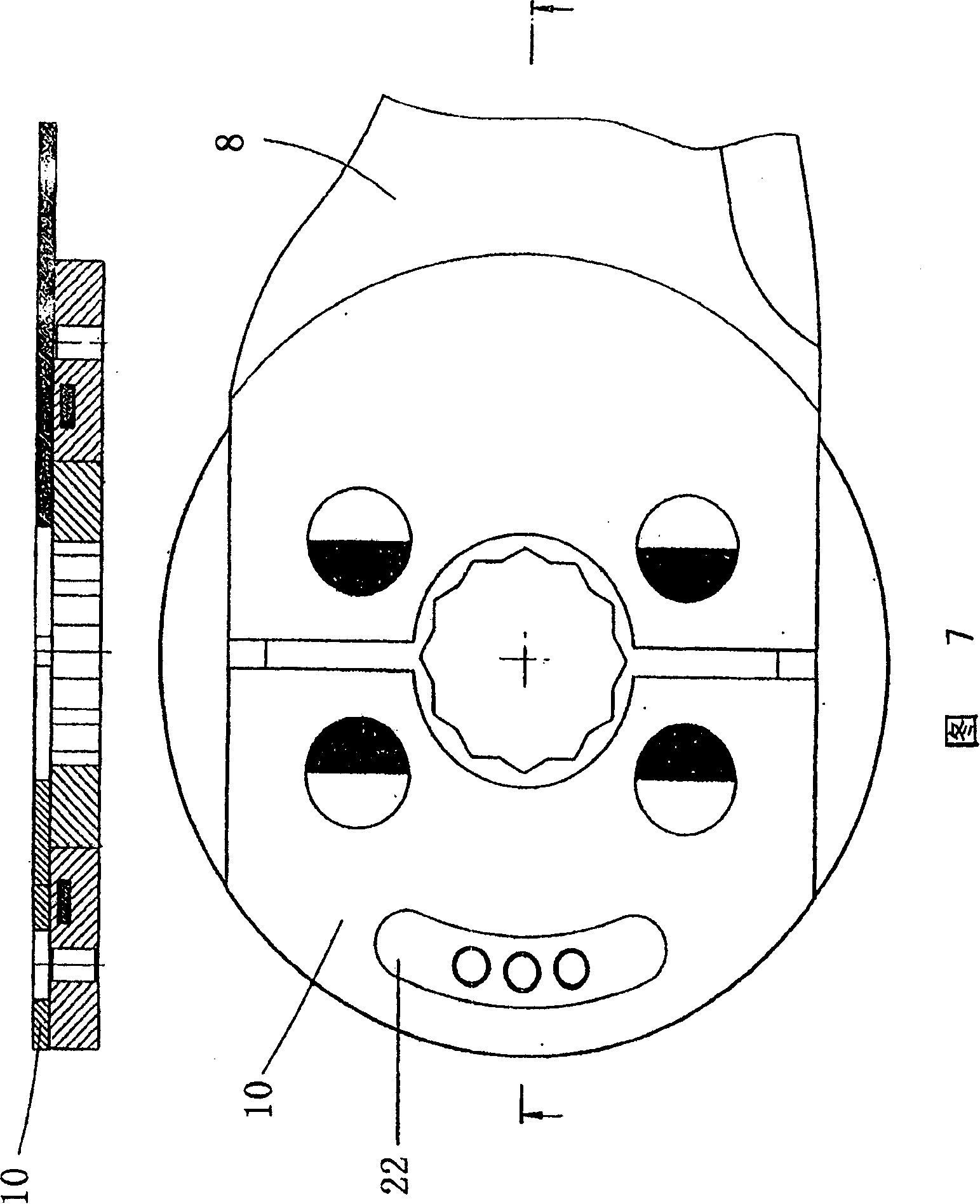

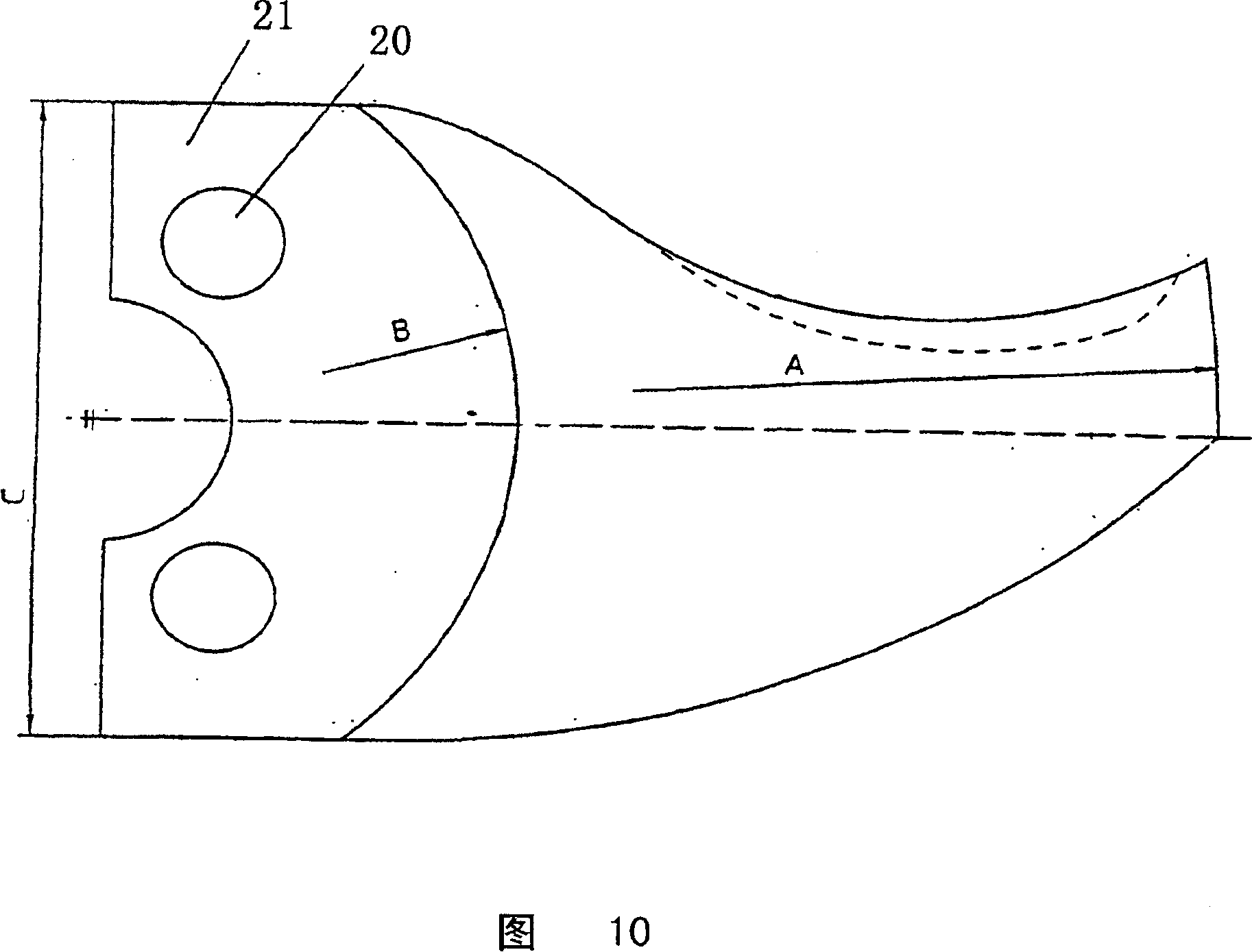

[0043] figure 1An embodiment of the cutter head disc 1 according to the invention is shown, comprising a metal core 2 and a plastic sheath 3 . According to the invention, the core 2 is encapsulated by a plastic sheath 3 by casting so that, without further provision, there is an interlocking and / or frictional engagement between the two parts and material cannot collect between the metal core and the plastic sheath. The exterior of the metal core is preferably provided with structures, such as ribs, which improve the bond between the core 2 and the plastic skin. It is preferred to mount a 12 edge socket for the bit drive shaft in the metal core. Also provided in the metal core are recesses 18 which in each case can accommodate an eccentric fixing bolt with which the knife (not shown) can be mounted on the cutter head disc . In the present case, the eccentric fixing bolt 4 is inserted into the groove 18 . Each eccentric fixing bolt has a disc-shaped head 4' mounted eccentric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com