Automobile air conditioner system

An automotive air-conditioning system and air-conditioning housing technology, applied in vehicle components, air handling equipment, lighting and heating equipment, etc., can solve problems such as turbulent flow, icing on the surface of the evaporator core, abnormal air conditioning, etc., and achieve stable wind pressure. , Improve heating and cooling capacity, prevent surface icing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

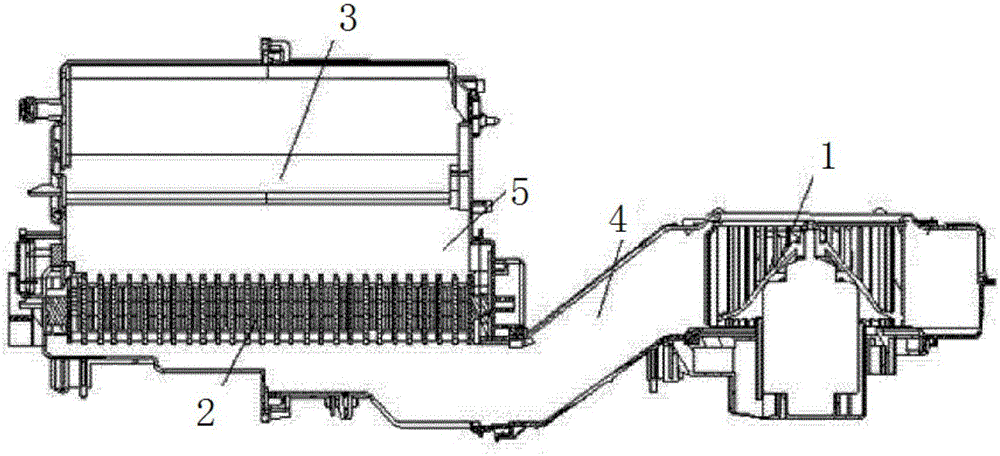

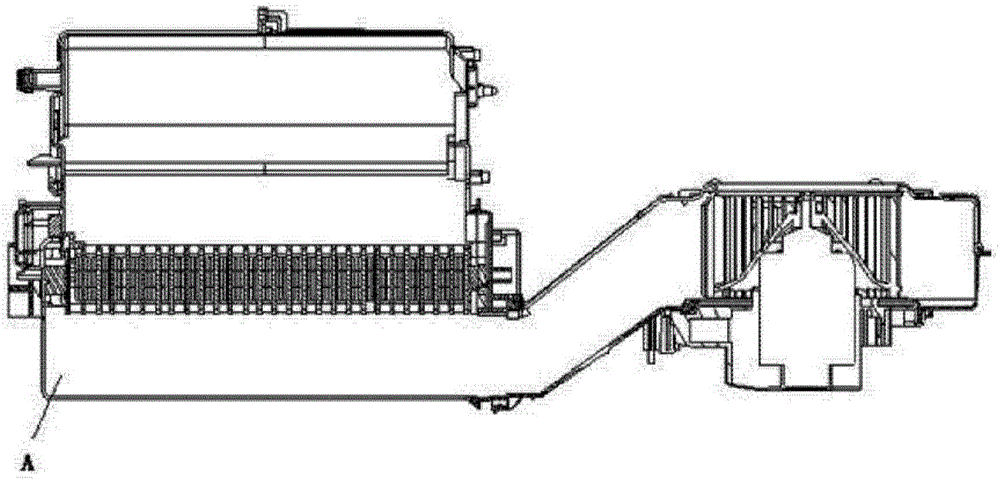

[0013] Such as figure 1 A car air-conditioning system shown includes an air-conditioning housing, and a blower 1, an evaporator core 2, and a heater core 3 arranged in the air-conditioning housing. The air flow channel 4 is connected, and the shell below the evaporator core 2 is in a stepped structure. The guide air duct 4 forms a stepped air duct. An air outlet channel 5 is provided between the evaporator core body 3 and the heater core body 3 . The heater core 3 communicates with the air outlet of the air conditioner housing.

[0014] The air volume entering the evaporator core is evenly distributed and the wind pressure is stable, which is beneficial to prevent the surface of the evaporator core from freezing, and the uniform air volume distribution improves the heating and cooling capacity of the system to meet customer requirements.

[0015] The wind passes through the blower to the diversion air duct, and enters the step-shaped air inlet section below the evaporator ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com