Integrally tilting type fixing grate plate resistant to heat and abrasion

A tilting, grate plate technology, applied in lighting and heating equipment, processing discharged materials, furnace components, etc., can solve the problems of poor material fluidity, poor high temperature resistance, and increased use costs, so as to improve strength and flow sex, weight reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

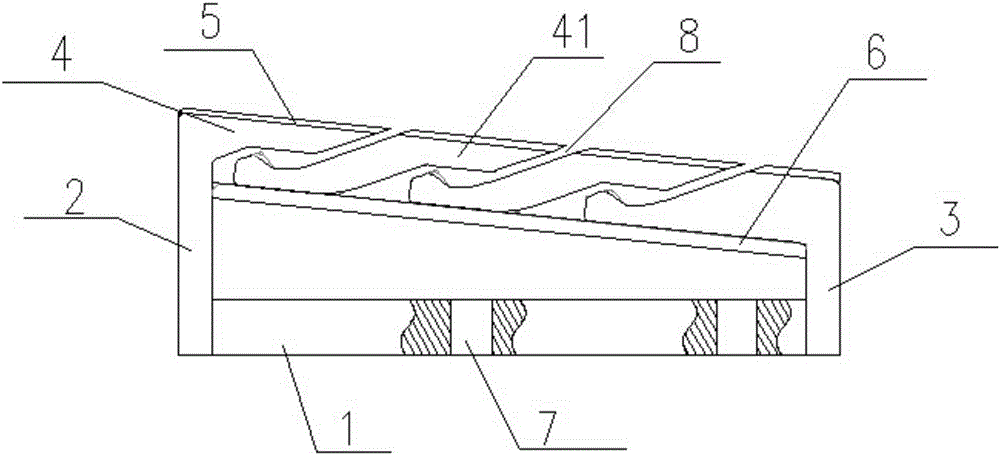

[0018] figure 1 The specific embodiment of the present invention is shown: a heat-resistant and wear-resistant integral inclined fixed grate, including a fixed grate body and an ear seat 1, and the fixed grate body includes a left support plate 2, a right support plate 3 and an inclined grate Plate 4, one end of the inclined grate plate 4 is arranged on the left support plate 2, and the other end is arranged on the right support plate 3, and the left support plate 2 and the right support plate 3 are respectively arranged on both sides of the ear seat 1, And be connected with ear seat 1, described ear seat 1 is provided with installation hole 7, the lower end of described inclined grate plate 4 is provided with stiffener plate 6, and described inclined grate plate 4 is provided with several grate slits 8, so The reinforcing rib plate 6 is arranged at the middle position of the lower end of the grate slit 8.

[0019] In this embodiment, the angle between the inclined grate plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com