Bicycle crankset with variable resisting arm

A resistance arm and bicycle technology, applied in vehicle components, vehicle gearboxes, chain/belt drives, etc., can solve the problem that the crankset cannot automatically change the length value of the resistance arm independently, so as to achieve smooth and smooth force generation and fast rotation speed. , the effect of easy riding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

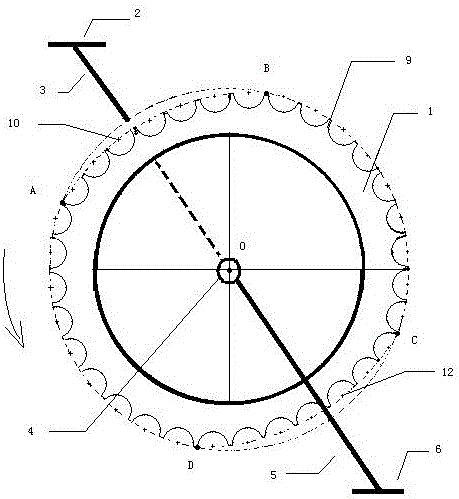

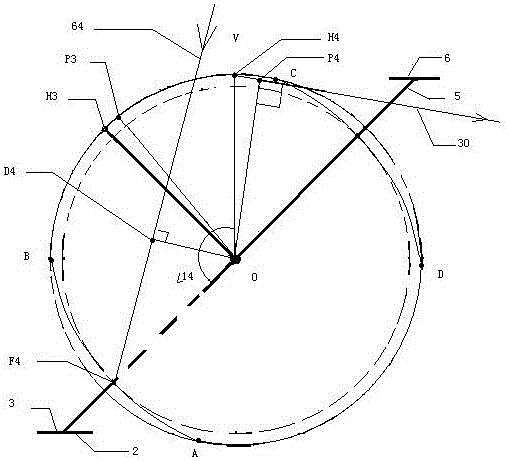

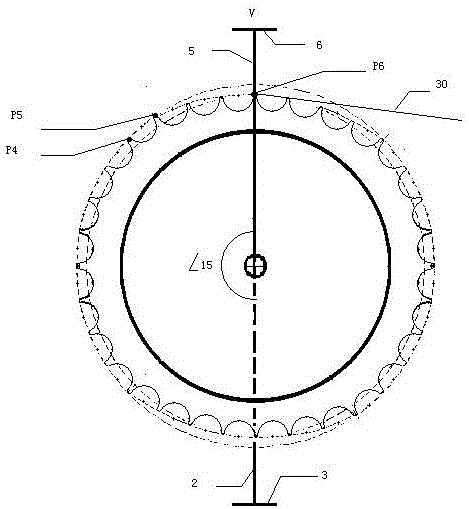

[0026] In the first stage, turn the variable resistance arm crankset 1 counterclockwise, from image 3 Start at zero o'clock as shown, that is, point V starts to rotate counterclockwise, and at this moment, the force point of the crankset and chain 30 resistance is H1. like Figure 4 As shown, the force distance O-H1 and the resistance arm O-P1, the length of the resistance arm O-P1 has passed the longest resistance arm O-P5 in the previous standard arc area, starting from the beginning of the smooth transition area, point A The transition to O-P1 becomes shorter, at which point power starts to turn that crankset. According to the formula: power arm*power=resistance arm*resistance, it can be known that the shorter resistance arm O-P1 is less labor-saving. Figure 5 shown. The resistance arm is gradually increased from O-P1 in the previous smooth transition zone to the maximum resistance arm O-P2 in the standard arc zone, such as Image 6 shown. Starting from point V, turn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap