Photochromic epoxy resin composition, cured product thereof, and preparation method and application thereof

An epoxy resin curing and epoxy resin technology, applied in chemical instruments and methods, color-changing fluorescent materials, optics, etc., can solve the problems of insufficient mechanical strength, limited application places, complicated and tedious procedures, etc., and achieve simple equipment and easy control. , the effect of rich functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0055] Another aspect of the embodiments of the present invention also provides a method for preparing a photochromic epoxy resin cured product, which includes: curing the photochromic epoxy resin composition at 80-200°C for 2-6 hours, A photochromic epoxy resin cured product was obtained.

[0056] Further, the components used to synthesize the cured photochromic epoxy resin include:

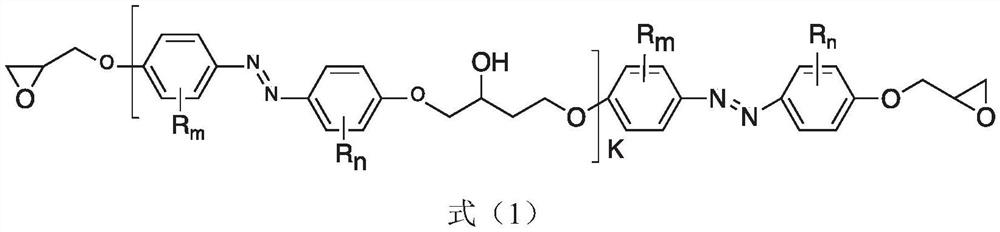

[0057] Component A: It is an azobenzene epoxy resin with the following structure (1):

[0058]

[0059] R m and R n Can be at least one of H, F, Cl, Br, I, methyl, ethyl, propyl, isopropyl, butyl, isobutyl, nitro, methoxy, k is an integer ≥ 0 , m takes an integer from 1 to 4, and n takes an integer from 5 to 8;

[0060] Component B: Aliphatic epoxy resin or aromatic epoxy resin;

[0061] Component C: curing agent.

[0062] Further, the preparation method of the cured photochromic epoxy resin specifically includes: reacting the mixture comprising component A, component B and curing agent...

Embodiment 1

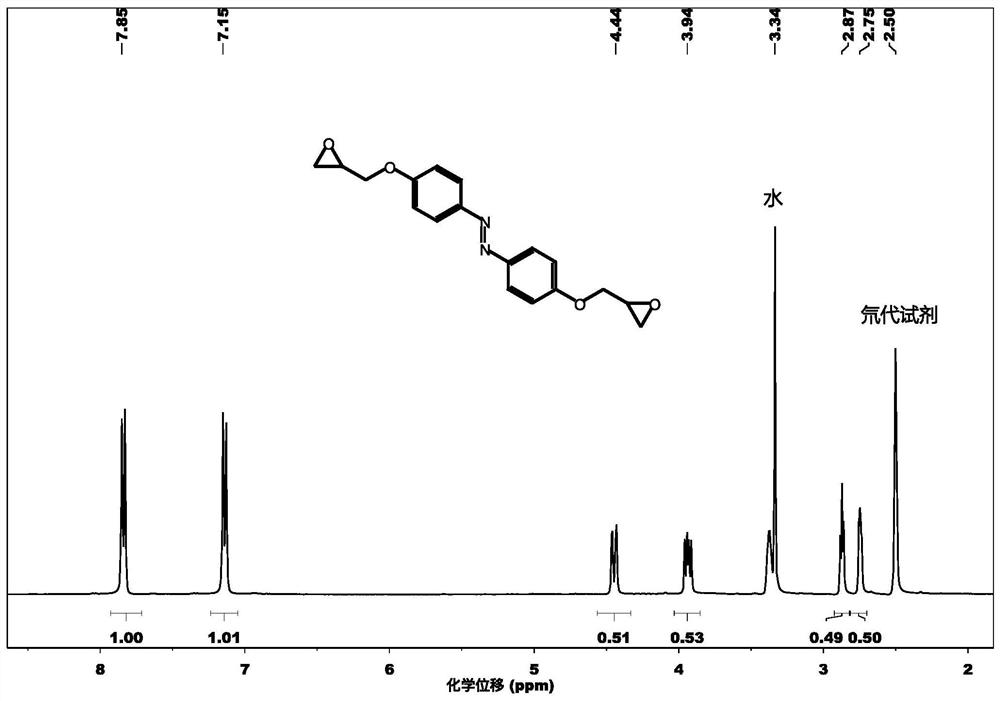

[0086] Azobenzene epoxy resin (formula 8), bisphenol A epoxy resin (formula 4) are blended by weight 0.5:99.5, then add curing agent (diaminodiphenylmethane, based on azobenzene epoxy resin and 60% of the total mass of bisphenol A epoxy resin) mixed evenly, adding acetone to make the solid content 50wt%, coating the polyester film with a dry film thickness of 20 μm, and keeping the solvent at 80°C and 200°C for 2 hours The epoxy resin coating was obtained, the friction resistance test was 700 times (load 600g), the pencil hardness was 4H, and the photochromic response speed was 10 seconds. Wherein, the 1H-NMR spectrum of the azobenzene epoxy resin monomer of the present embodiment please refer to figure 1 shown.

Embodiment 2

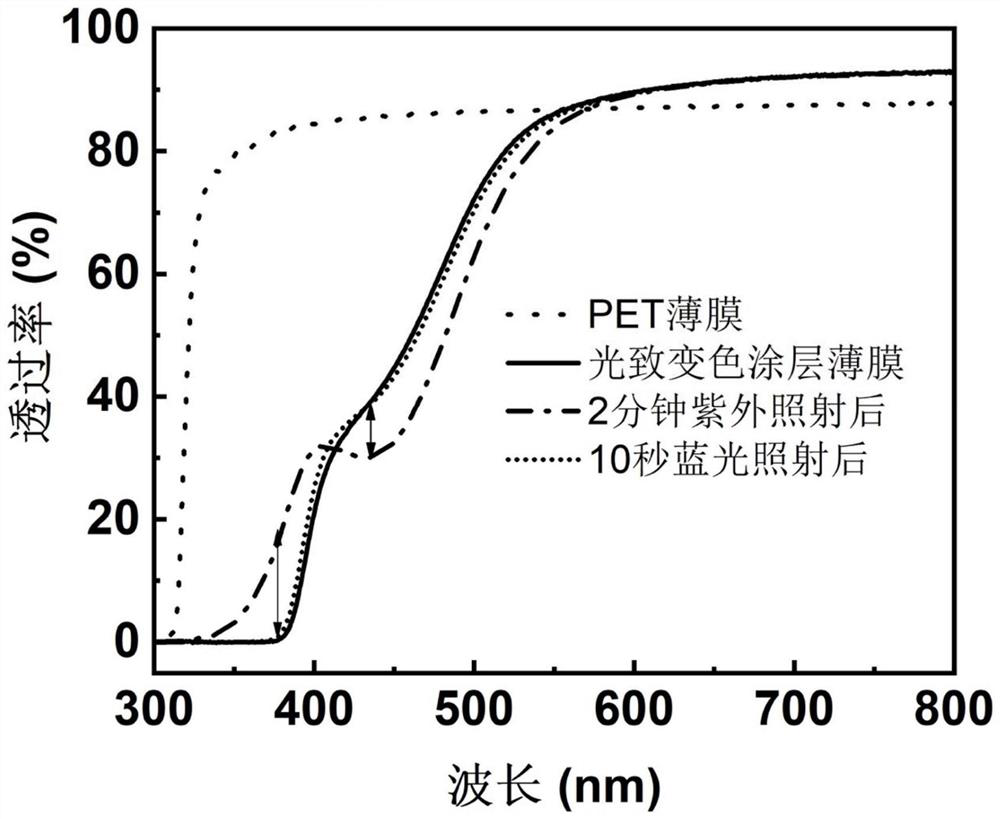

[0088] Azobenzene epoxy resin (formula 8), bisphenol S epoxy resin (formula 6) are mixed by weight 10:90, then add curing agent (diaminodiphenylmethane, based on azobenzene epoxy resin and 60% of the total mass of bisphenol S epoxy resin) and mix evenly, add acetone so that the solid content is 50wt%, and coat the polyester film with a dry film thickness of 20 μm. The epoxy resin coating was obtained, the friction resistance test was 800 times (load 500g), the pencil hardness was 4H, and the photochromic response speed was 10 seconds. For the photochromic absorption curve of the photochromic epoxy resin prepared in this embodiment, please refer to figure 2 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com