Autorotation field-effect water treating machine

A technology of automatic rotation and field effect, applied in the direction of magnetic/electric field water/sewage treatment, etc., can solve problems such as unsatisfactory results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

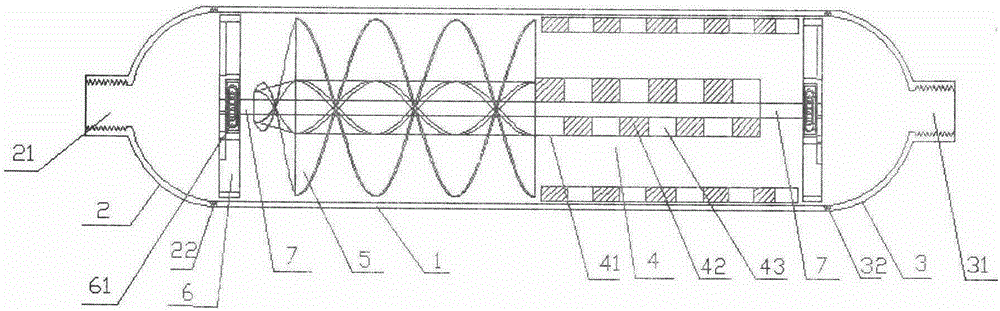

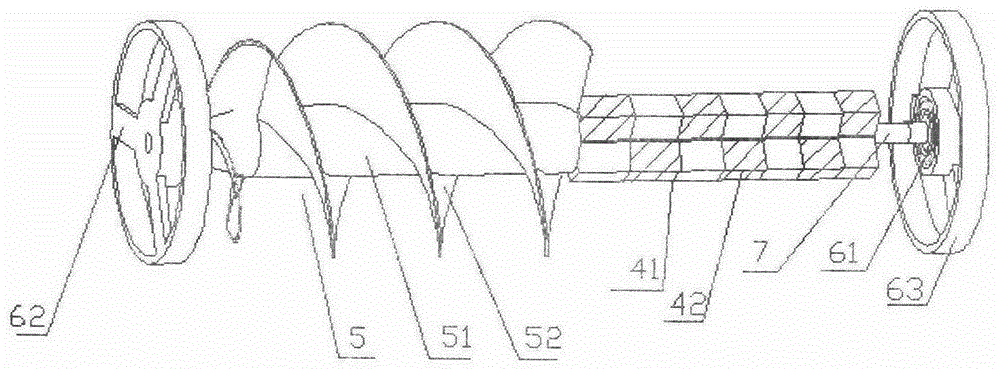

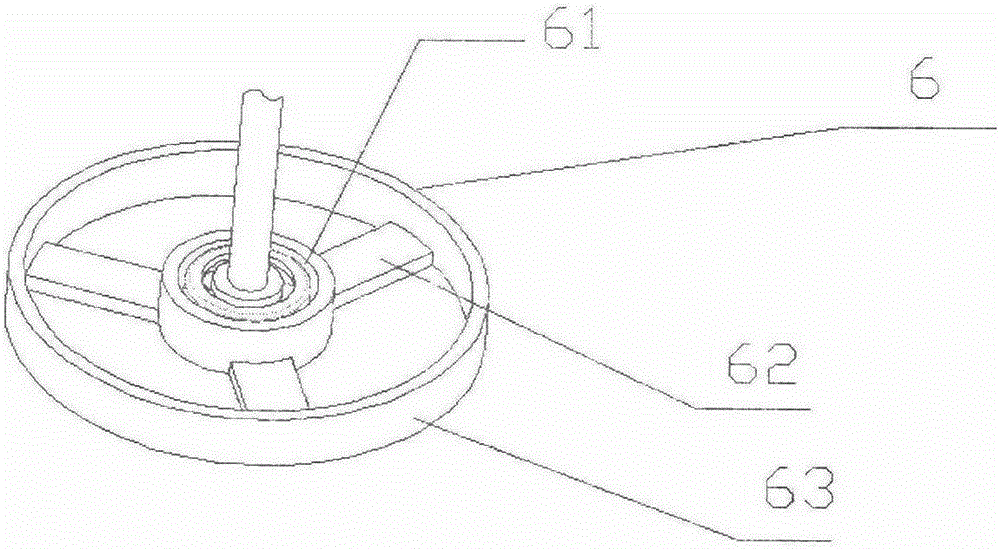

[0022] Embodiment 1: an automatic rotating field effect water treatment machine, comprising a casing 1, a water inlet 21, and a water outlet 31, characterized in that: a hydrodynamic generator 5, a magnetic hub 4, and a magnetic stator are arranged in the casing 1 8. The hydrodynamic generator 5 and the magnetic pivot 4 are solidly integrated; the two ends of the hydrodynamic generator 5 and the magnetic pivot 4 are respectively provided with rotating shafts 7, and are connected with the bearings 61 at both ends of the casing 1; A magnetic stator 8 is provided at a position corresponding to the magnetic pivot 4, and the magnetic pivot 4 rotates in the magnetic stator 8; the water inlet end cover 2 and the water outlet end cover 3 seal the hydrodynamic generator 5 and the magnetic pivot 4 in the casing 1 .

[0023] Described a kind of automatic rotating field effect water treatment machine is characterized in that: hydrodynamic generator 5 is made of cylinder 51, power wing 52;...

Embodiment 2

[0029] Embodiment 2: an automatic rotating field effect water treatment machine, comprising a casing 1, a water inlet 21, and a water outlet 31, characterized in that: a hydrodynamic generator 5, a magnetic hub 4, and a magnetic stator are arranged in the casing 1 8. The hydrodynamic generator 5 and the magnetic pivot 4 are solidly integrated; the two ends of the hydrodynamic generator 5 and the magnetic pivot 4 are respectively provided with rotating shafts 7, and are connected with the bearings 61 at both ends of the casing 1; A magnetic stator 8 is provided at a position corresponding to the magnetic pivot 4, and the magnetic pivot 4 rotates in the magnetic stator 8; the water inlet end cover 2 and the water outlet end cover 3 seal the hydrodynamic generator 5 and the magnetic pivot 4 in the casing 1 .

[0030] Described a kind of automatic rotating field effect water treatment machine is characterized in that: hydrodynamic generator 5 is made of cylinder 51, power wing 52;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com