Pipeline steel with resistance to microbiological corrosion

A technology with corrosion performance and microbial resistance, applied in the field of pipeline steel, it can solve the problems of not considering the microbial corrosion resistance of materials, and achieve the effects of excellent microbial corrosion resistance, improved matrix strength, and improved precipitation behavior.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, the chemical composition of the pipeline steel is (% by weight):

[0028] C: 0.030%, Si: 0.14%, Mn: 1.09%, Cu: 1.06%, Ni: 0.32%, Mo: 0.31%, Cr: 0.32%, Nb: 0.05%, V: 0.02%, the rest is Fe; impurities The element content is: S: 0.0011%, P: 0.0050%.

[0029] The aging heat treatment process of the above-mentioned pipeline steel is as follows: after hot rolling, the temperature is raised to 500° C., kept for 1 hour, and then air-cooled.

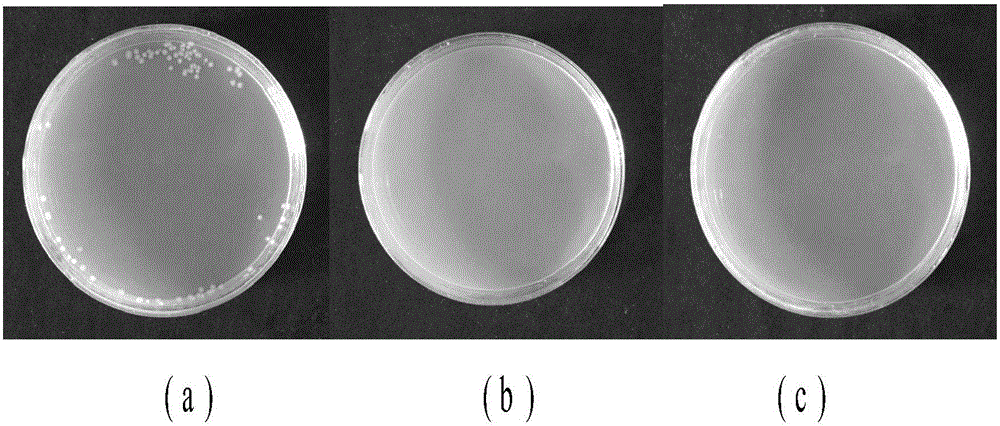

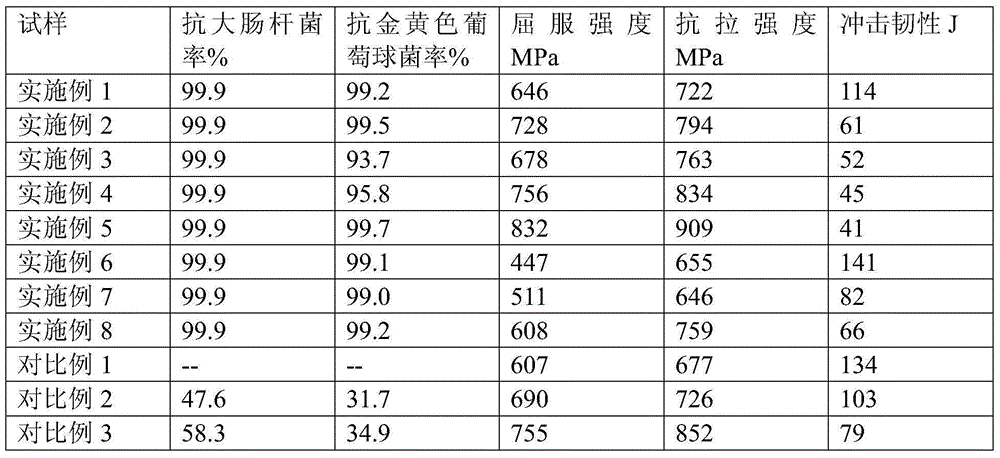

[0030] Antibacterial results such as figure 1 As shown in (b), it can be seen that compared with the reference sample X80 commercial pipeline steel, the pipeline steel of the present invention has excellent bactericidal ability, and the bactericidal rate and mechanical performance tests are shown in Table 1.

Embodiment 2

[0032] In this embodiment, the chemical composition of the pipeline steel is (% by weight):

[0033] C: 0.020%, Si: 0.12%, Mn: 1.03%, Cu: 1.46%, Ni: 0.31%, Mo: 0.31%, Cr: 0.31%, Nb: 0.05%, V: 0.02%, the rest is Fe; impurities The element content is: S: 0.0011%, P: 0.0050%.

[0034] The aging heat treatment process of the above-mentioned pipeline steel is as follows: after hot rolling, the temperature is lowered to 500°C, kept for 1 hour, and then air-cooled. The sterilization rate and mechanical performance tests are shown in Table 1.

Embodiment 3

[0036] In this embodiment, the chemical composition of the pipeline steel is (% by weight):

[0037] C: 0.035%, Si: 0.18%, Mn: 0.82%, Cu: 1.23%, Ni: 0.37%, Mo: 0.39%, Cr: 0.40%, Nb: 0.04%, V: 0.02%, the rest is Fe; impurities The element content is: S: 0.0014%, P: 0.0050%.

[0038] The aging heat treatment process of the above-mentioned pipeline steel is as follows: after hot rolling, the temperature is lowered to 500°C, kept for 1 hour, and then air-cooled. The sterilization rate and mechanical performance tests are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com