Post-processing Method of Gradient Friction Wrap Yarn Hairiness

A yarn and gradient technology, which is applied in the post-processing field of gradient friction wrapping yarn hairiness, can solve the problems of hairiness reduction, increased energy consumption, wear and loss of rotating parts, etc., and achieves the improvement of friction wrapping speed and strength, and solves the problem Yarn slubs, the effect of preventing fiber aggregation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

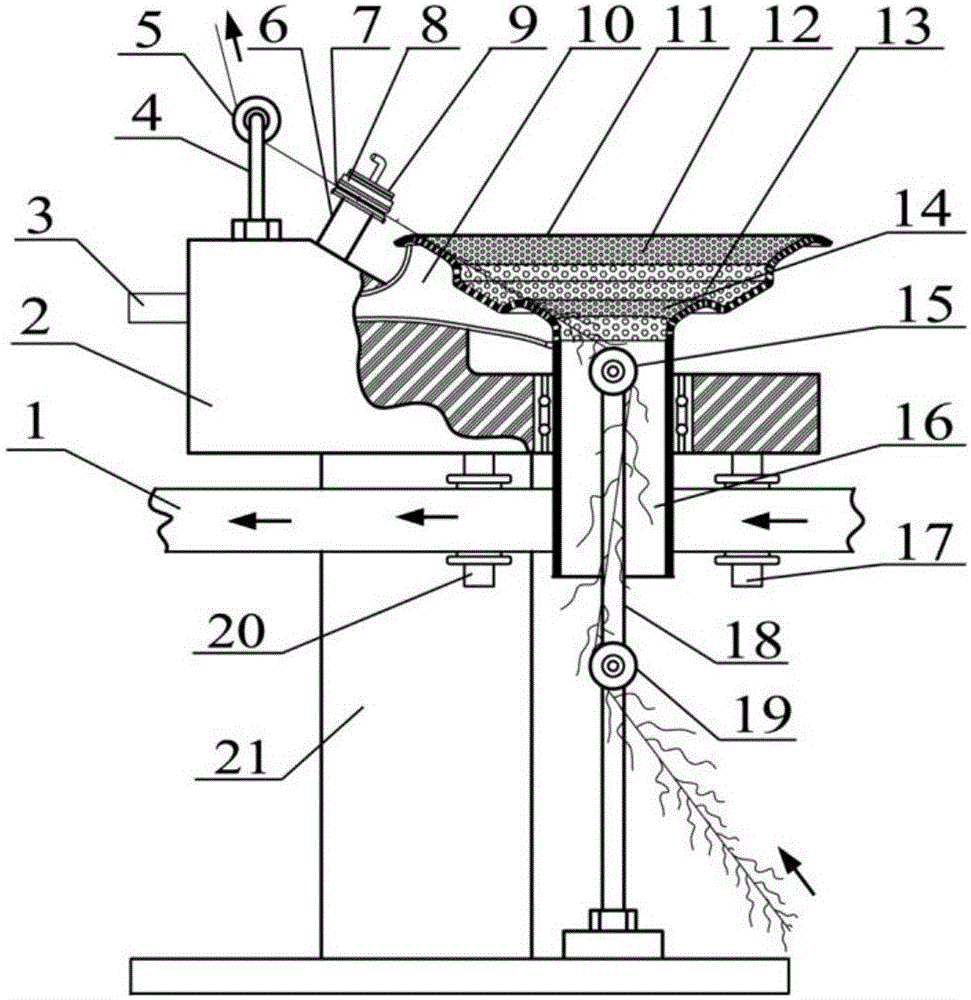

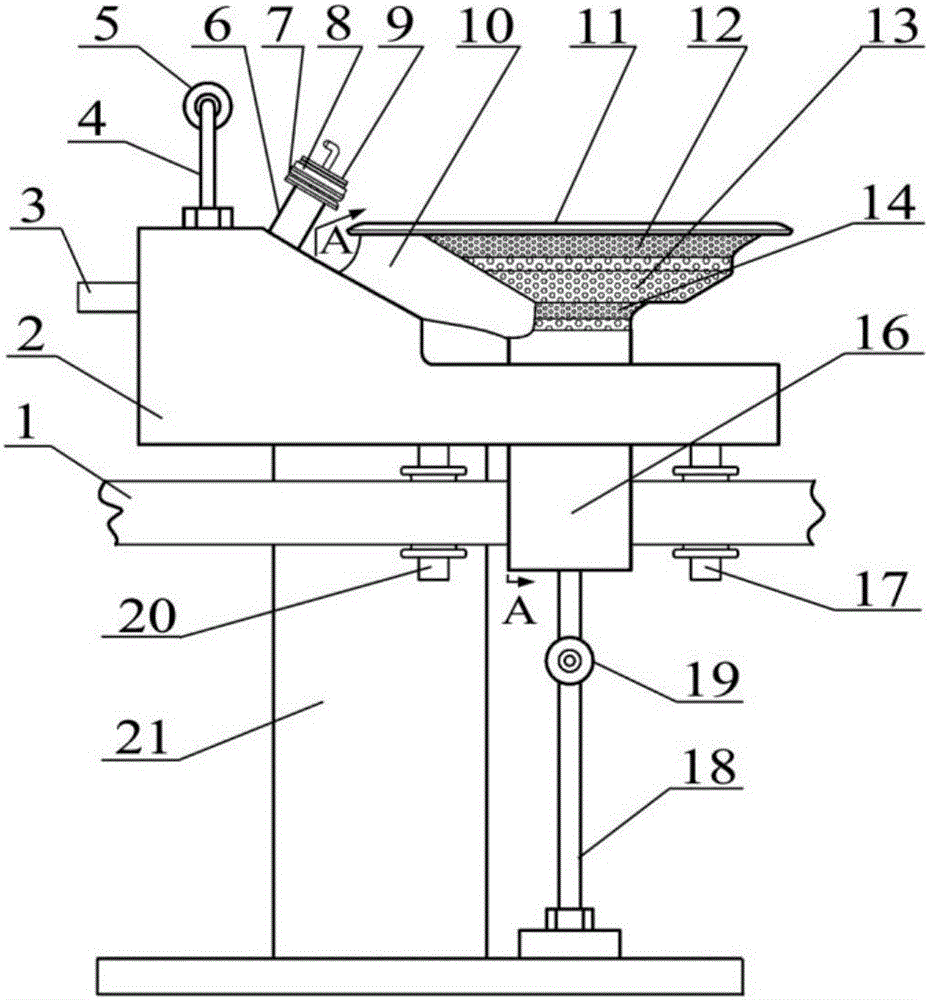

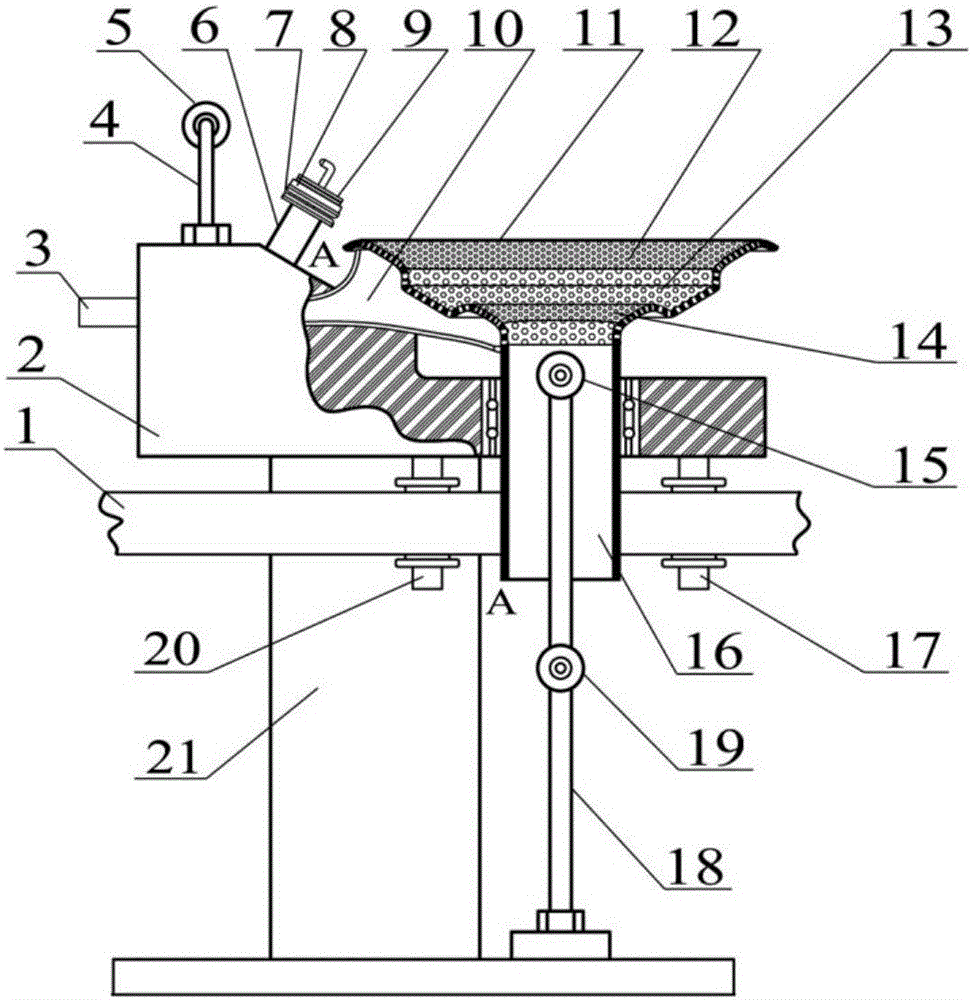

[0023] Example 1: Gradient wrapping treatment of Z-twisted cotton yarn hairiness in the warping process

[0024] Fix the yarn hairiness gradient wrapping device through the mounting table on a row of yarn guide rods at the yarn output end of the creel of the warping machine by using screw and hook fixing devices. The yarn hairiness gradient wrapping device is located between the yarn guide rod and the yarn guide rod Between the telescopic buckles; the yarn hairiness gradient wrapping device is externally connected to the transmission motor through the transmission belt, which drives the funnel-type friction device to rotate counterclockwise at a high speed of 8000 rpm. The heat setting device is connected to an external power supply to make the ironing yarn groove When the temperature rises to 135°C, the taper between the upper cone wall 12 and the lower cone wall 14 of the hollow cone 11 and the cross section of the hollow shaft 16 is 3:1, the upper cone wall 12 has a wall wid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com