Inertial navigation platform torque motor brush holder automatic running-in device

A technology of a torque motor and a brush holder, which is applied to the field of automatic running-in device for a torque motor brush holder of an inertial navigation platform, can solve the problems of poor running-in precision and low work efficiency, and achieve the effects of improving running-in efficiency, running-in efficiency and improving running-in accuracy.

Inactive Publication Date: 2012-03-14

FLIGHT AUTOMATIC CONTROL RES INST

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the running-in of the torque motor brush holder of the inertial navigation platform is manually operated, which not only has low work efficiency, but also has poor running-in accuracy.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

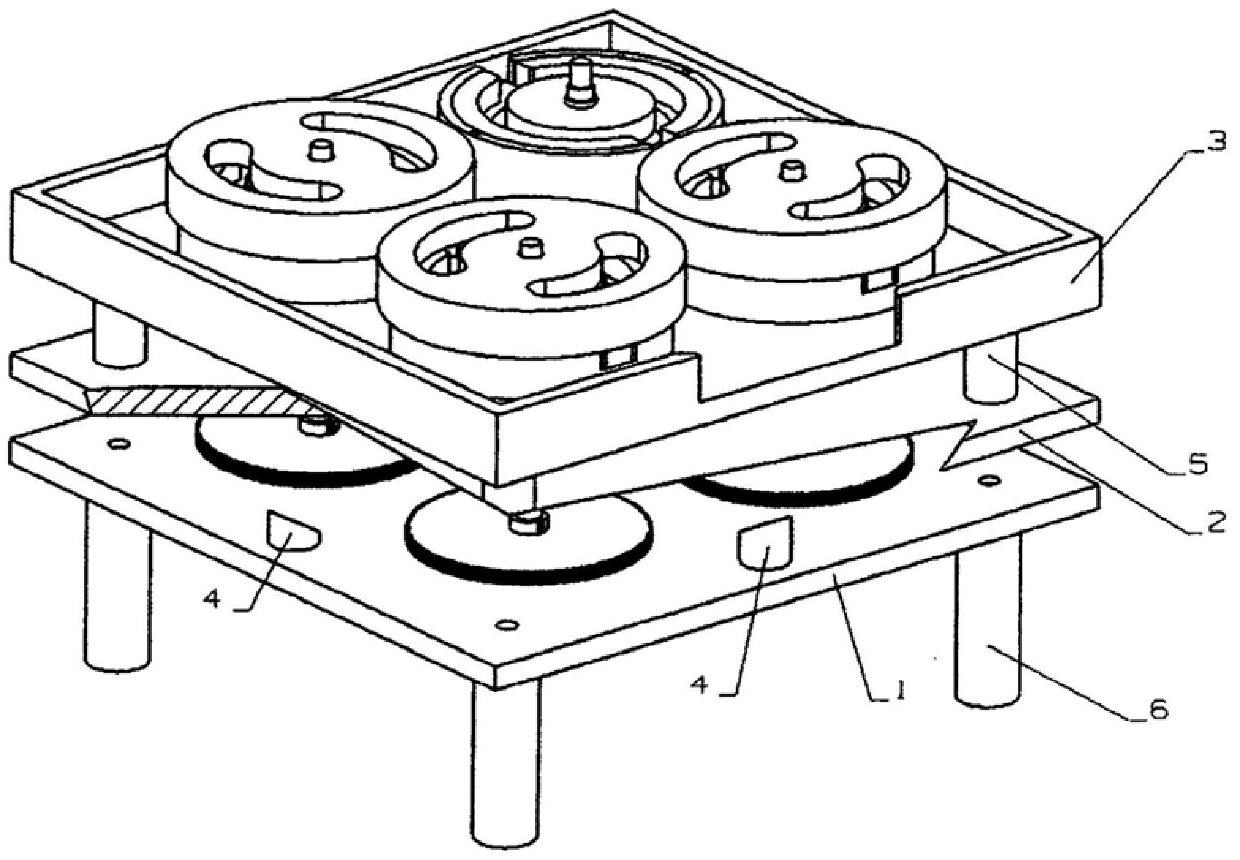

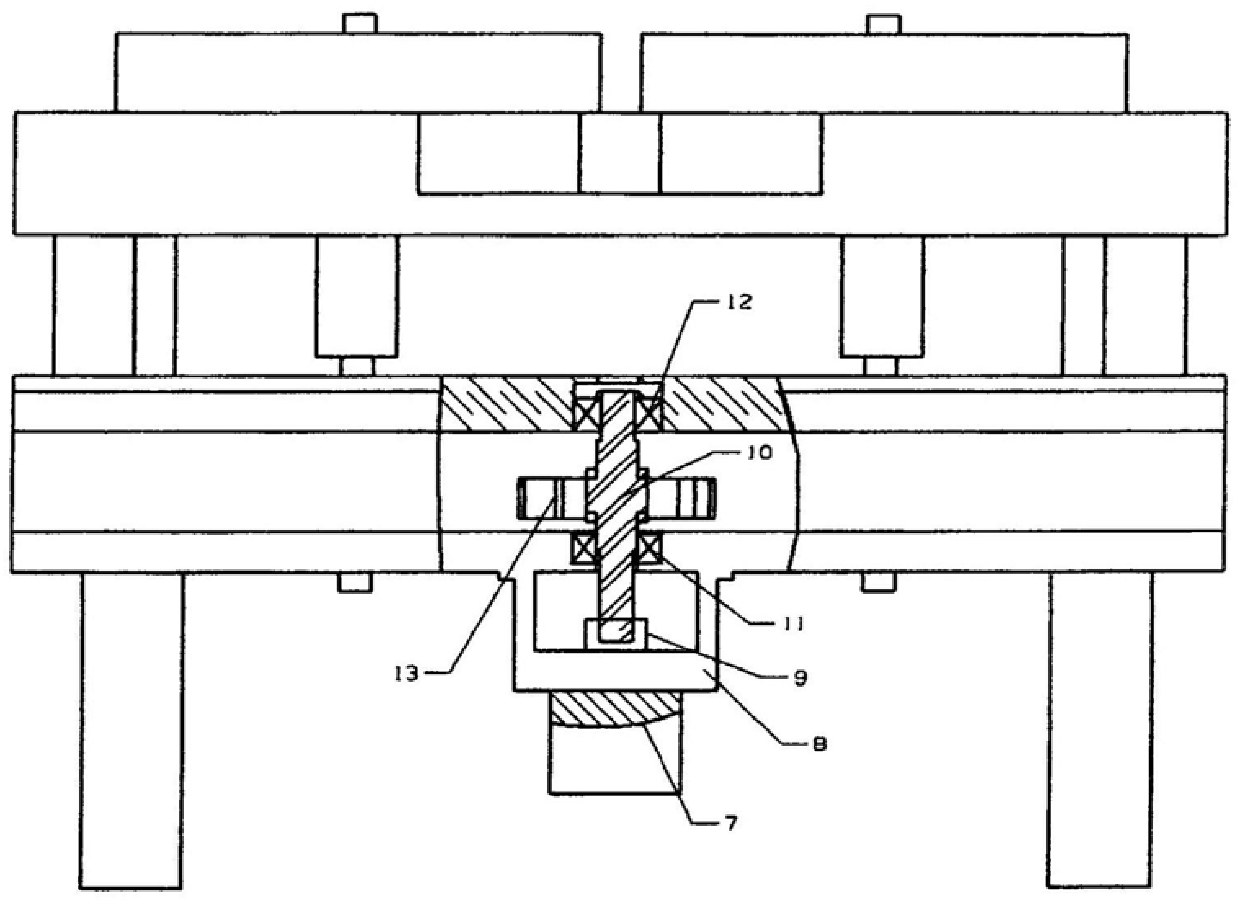

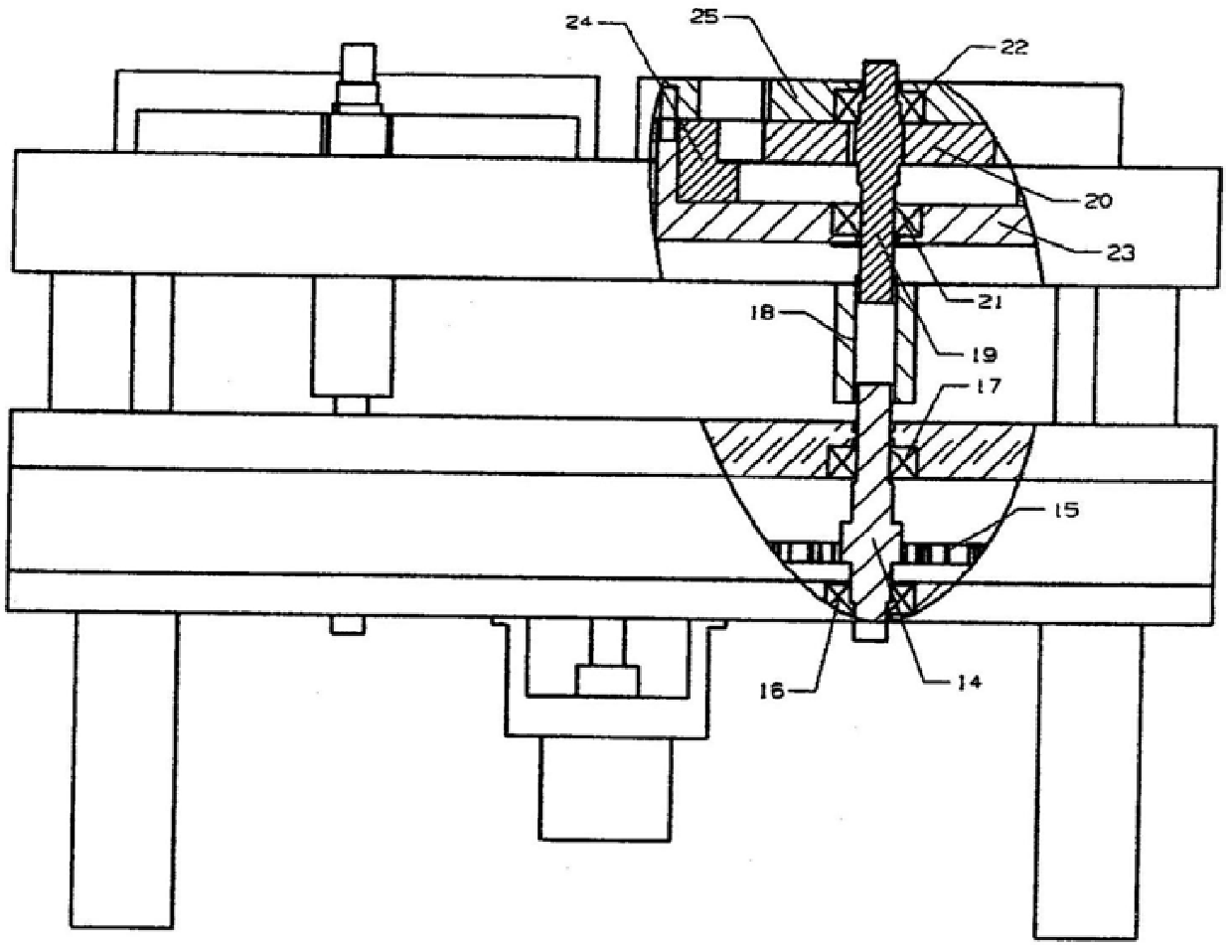

The invention belongs to the motor manufacturing technology, and relates to an automatic running-in device for brush holders of moment motors of various inertial navigation platforms. It consists of a three-layer frame, a driving shaft fixed on the three-layer frame, and four driven shafts driven by the driving shaft with the same structure. The drive shaft system is composed of drive motor [7], motor bracket [8], motor coupling [9], drive gear shaft [10], drive shaft lower bearing assembly [11], drive shaft upper bearing assembly [12] and drive shaft Gear [13] is formed. The driven shaft system consists of a driven gear assembly vertically installed between the bottom plate [1] and the middle plate [2] and a running-in mechanism coaxially installed on the pallet [3]. The invention greatly improves the running-in efficiency and the running-in precision of the inertial navigation platform torque motor brush holder, and ensures the stability of product quality.

Description

Inertial navigation platform torque motor brush holder automatic running-in device technical field The invention belongs to the motor manufacturing technology, and relates to an automatic running-in device for brush holders of moment motors of various inertial navigation platforms. Background technique At present, the running-in of the moment motor brush frame of the inertial navigation platform is manually operated, which not only has low work efficiency, but also has poor running-in accuracy. Contents of the invention The object of the present invention is to provide an automatic running-in device for brush holders of moment motors of inertial navigation platforms with high running-in efficiency and high running-in precision. The technical solution of the present invention is: an automatic running-in device for inertial navigation platform torque motor brush holder, which is characterized in that it consists of a three-layer frame, a driving shaft fixed on the three-...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01M13/00F02B79/00H02K5/14

Inventor 刘炳刚王东辉苗笛赵炜

Owner FLIGHT AUTOMATIC CONTROL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com