Run-in test stand of gearbox of automobile

A technology of automobile transmission and test bench, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems of complex structure, low running-in efficiency, and difficult alignment, and achieve the effects of saving workshop space, improving running-in efficiency, and high running-in efficiency

Inactive Publication Date: 2010-11-10

力帆科技(集团)股份有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

This kind of transmission running-in test bench needs to be equipped with an engine, a detection device, a mounting bracket and other auxiliary mechanisms, which has a complex structure and takes up a large space; The bolts are installed on the crankcase shell of the engine assembly, and at the same time the main shaft of the transmission is connected with the spline on the clutch shaft. After running in one transmission, replace the other

Although this method is simple and does not require a separate running-in test bench, if a large number of transmissions need to be run-in, there are the following disadvantages: (1) The running-in efficiency is low. Disassemble the upper one, and then install another one. When assembling, the main shaft of the transmission to be run-in is connected to the shaft of the clutch. Because the main shaft of the transmission and the shaft of the clutch are not easy to align, it often takes a lot of time to align , therefore, the running-in efficiency is very low; (2) it is easy to damage the crankcase, because during the running-in, the casing of the transmission to be run-in must be installed on the crankcase with bolts, and after repeated running-in of multiple transmissions, the crankcase will be damaged due to the The crankcase needs to be replaced, and the splines on the clutch shaft are also easily damaged due to the repeated insertion of the transmission main shaft, which makes the running-in impossible

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

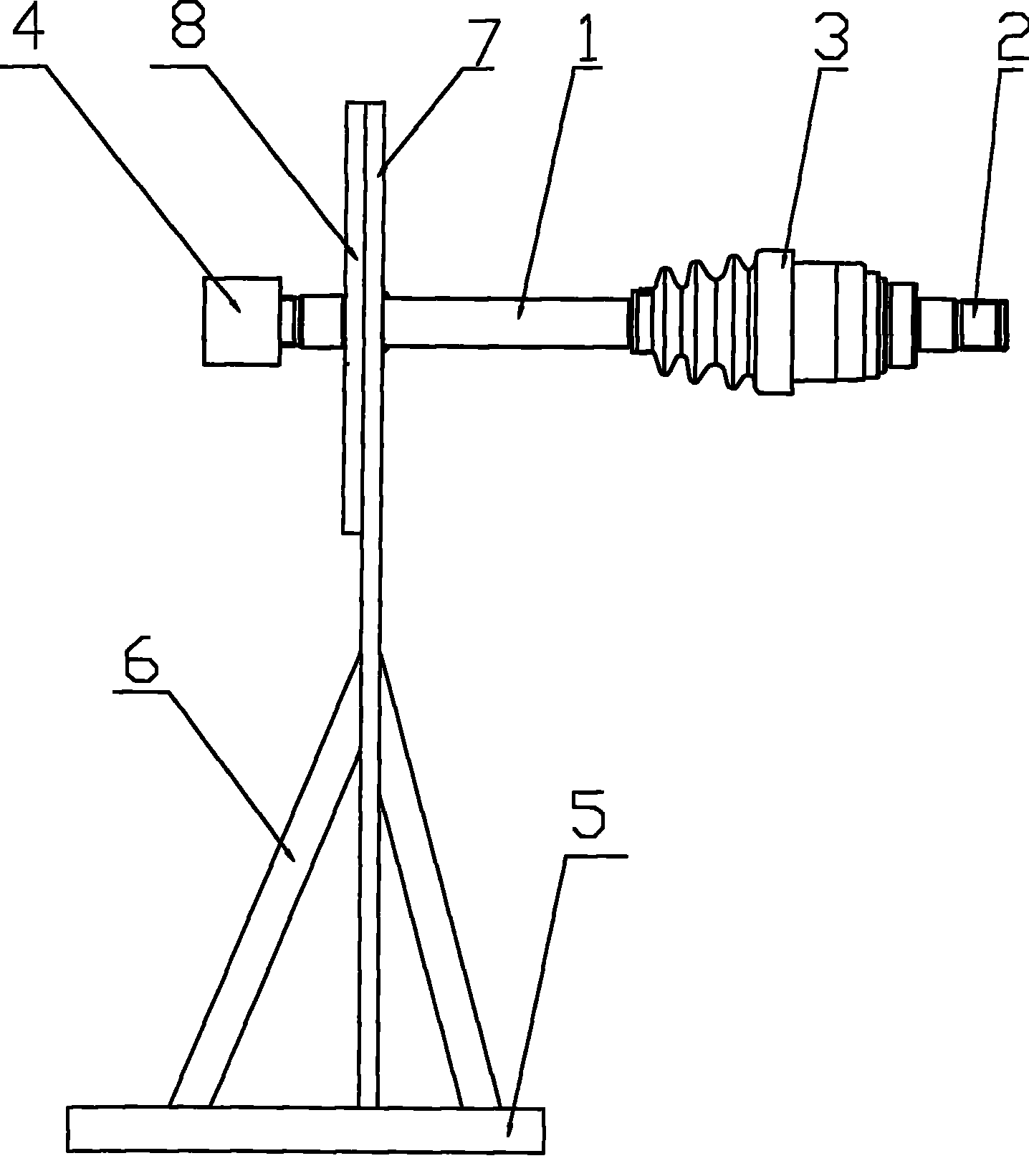

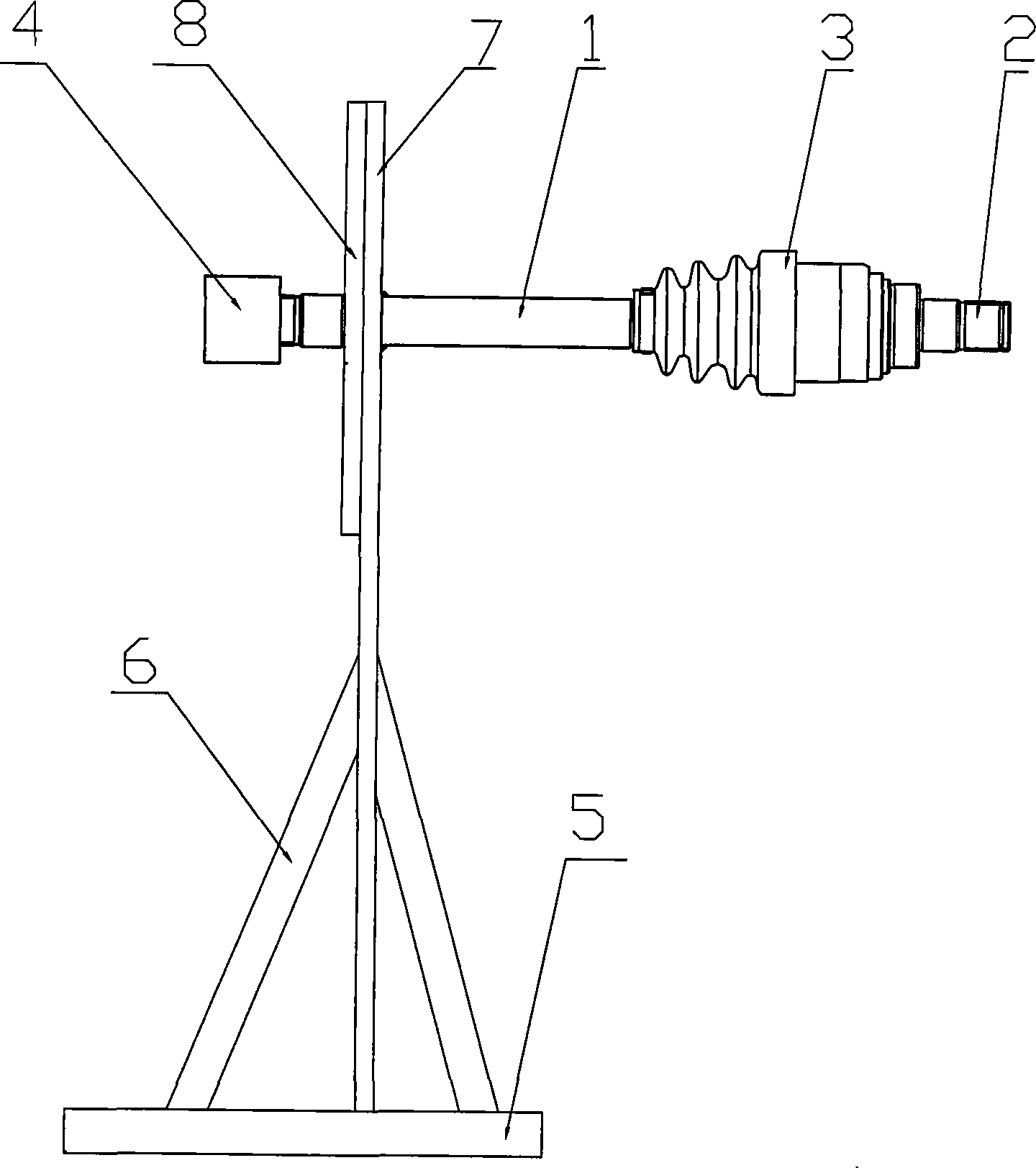

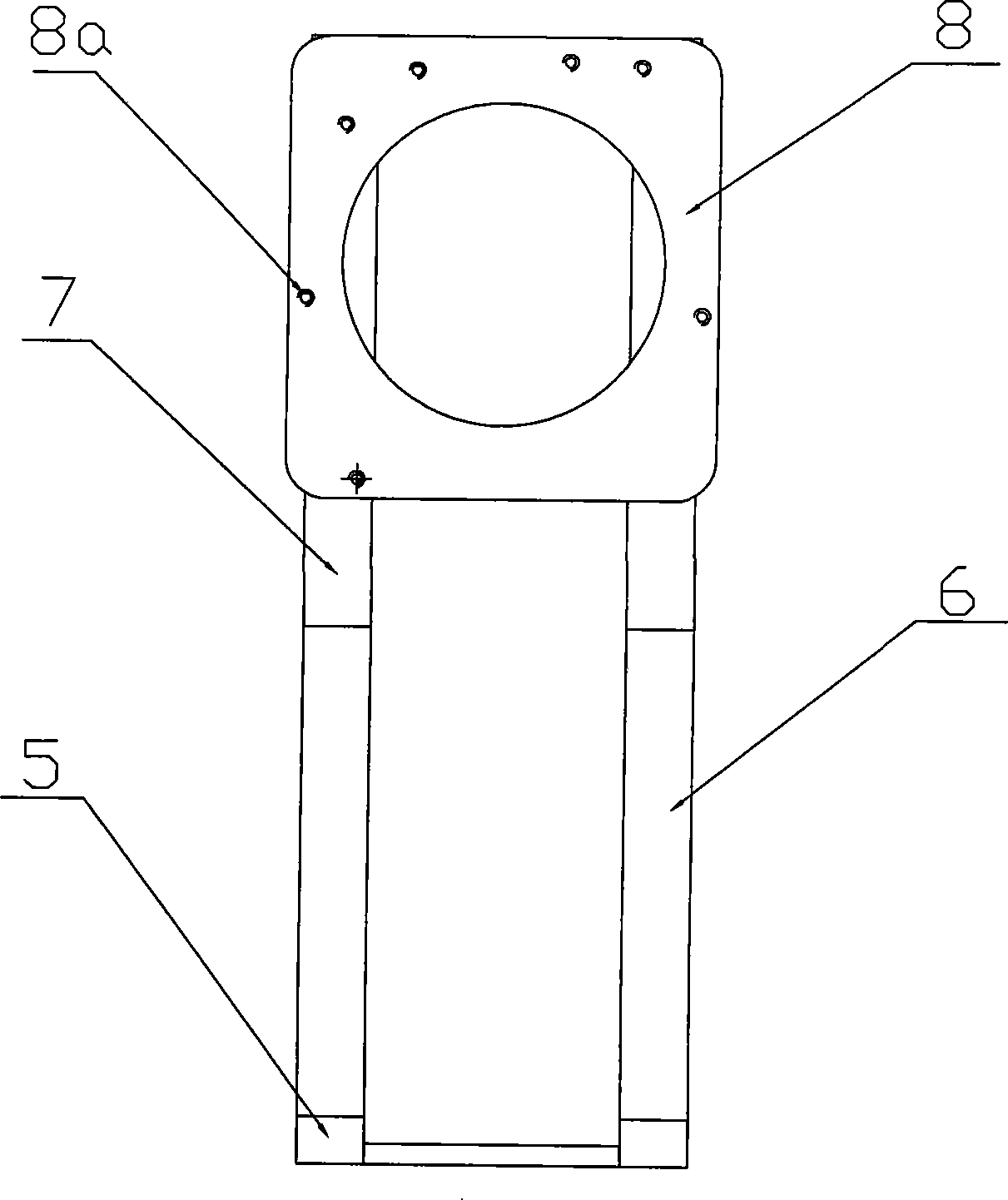

The invention discloses a run-in test stand of a gearbox of an automobile. The run-in test stand comprises a transmission shaft and a gearbox assembling stand, wherein the transmission shaft is formedby connecting a left transmission shaft and a right transmission shaft through a universal joint; the right end part of the right transmission shaft is provided with a spline, and the left transmission shaft is sleeved with a spline housing after the left end of the left transmission shaft penetrates through a connecting plate positioned on the stand. The invention enables the gearbox on an engine assembly to rotate to drive the gearbox to carry out a run-in test by the transmission shaft. During run-in, the gearbox to be run in is assembled, and then the spline housing is connected with a main shaft of the gearbox so as to carry out run-in, therefore, the run-in efficiency is greatly improved. Because the gearbox to be run in is installed on the connecting plate, the damage to the engineassembly is less. Because the run-in test stand of the gearbox does not need to be singly installed when the gearbox is run in, and the run-in can be carried out just on the test stand of the engineassembly, the factory space is saved.

Description

Automobile transmission running-in test bench technical field The invention relates to an inspection device of an automobile transmission, in particular to a test bench for running-in of an automobile transmission. Background technique In order to detect various performances of the transmissions produced, such as: whether there are abnormal noises during the operation of the transmission, whether the shifting is flexible, and whether there is oil leakage, a running-in test must be carried out before the transmission leaves the factory. In the whole vehicle production process, since the transmission is finally assembled on the engine assembly together with clutches and other components, people use the power provided by the engine to drive the transmission to run while running in the engine assembly. Run-in test. If the customer only needs a separate transmission, then the transmission must be run-in separately. At present, there are two ways to run-in the transmission alo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01M13/02

Inventor 唐年华

Owner 力帆科技(集团)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com