A fixed skirt plate suitable for the roller table of the cooling bed in the bar workshop

A roller table and skirt technology, applied in the field of production equipment in bar workshop, can solve the problems of increased maintenance workload, inconvenient maintenance and replacement, large wear of skirt plates, etc., to reduce maintenance workload, convenient maintenance and replacement, Stability-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

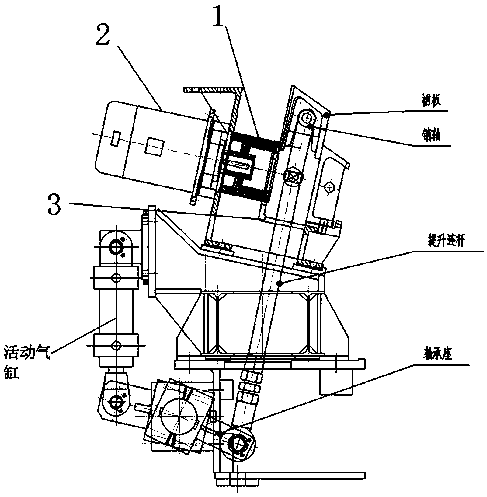

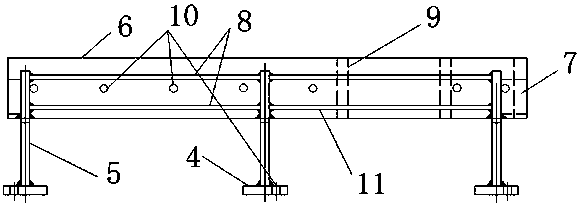

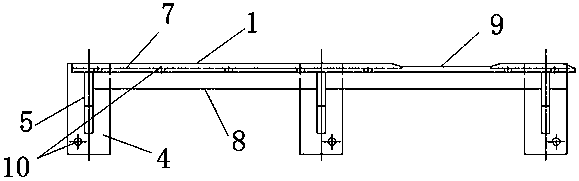

[0018] Embodiment 1: as figure 2 , 3 A fixed skirt plate suitable for the cooling bed roller table 1 in the bar workshop shown in and 4, the fixed skirt plate is installed on the side roller table support 3 of the cooling bed roller table 1, and the fixed skirt plate The plate is composed of skirt plate base 4, bracket 5, support plate 8, roller limit plate 6 and wear-resistant plate 12. The bracket 5 is vertically installed on the skirt plate base 4, and the same fixed skirt plate has at least Two brackets 5 are connected to each other by a support plate 8 between adjacent two brackets 5, and the top of the bracket 5 is provided with a vertically installed roller limit plate 6, and the roller limit plate 6 is installed On the side of the bracket 4 close to the cooling bed roller table 1, an installation groove 7 is provided on the outside of the roller table limiting plate 6, and the wear-resistant plate 12 is fixed and installed in the installation groove 7 by locking bolt...

Embodiment 2

[0019] Embodiment 2: as figure 2 , 3 As shown in and 4, the apron base 4 of the present invention is provided with a fixing screw hole 10, and the apron base 4 is fixedly installed on the roller table bracket 3 through a lock nut.

Embodiment 3

[0020] Embodiment 3: as figure 2 , 3 As shown in and 4, the bracket 5 of the present invention corresponds to the skirt board base 4 one by one; through the combined structure of multiple brackets 5 and the skirt board base 4, the overall fixing is ensured while saving the material consumption of the skirt board base 4 The stability of the apron 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com