Shock absorber limiting ring seat point welding device and method for welding limiting ring seat through same

A technology of spot welding device and limit ring, which is applied in welding equipment, resistance welding equipment, metal processing equipment and other directions, can solve the problems of difficulty in ensuring that the workpiece is balanced on the electrode, product quality is difficult to guarantee, and the balance between hands is poor. Simple, Quality Assured, Work-Effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

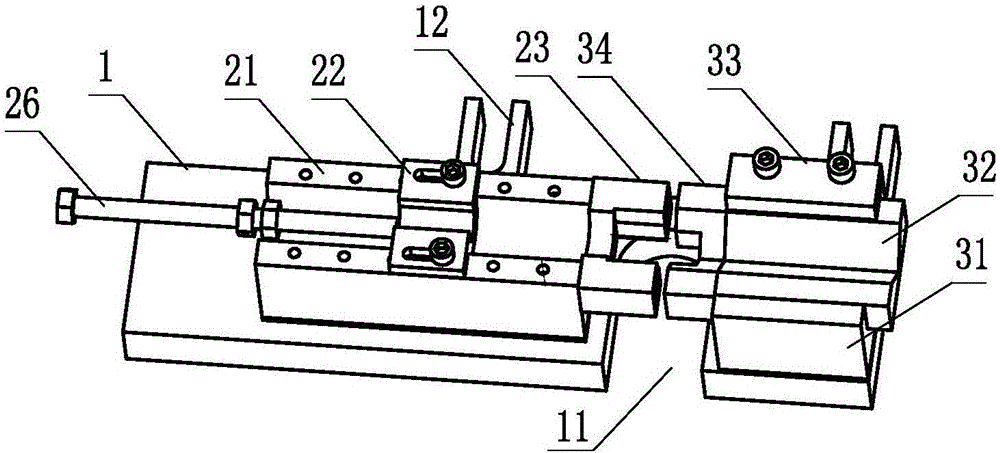

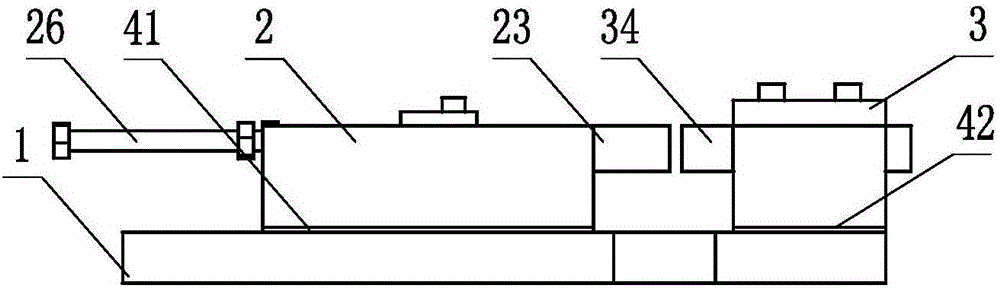

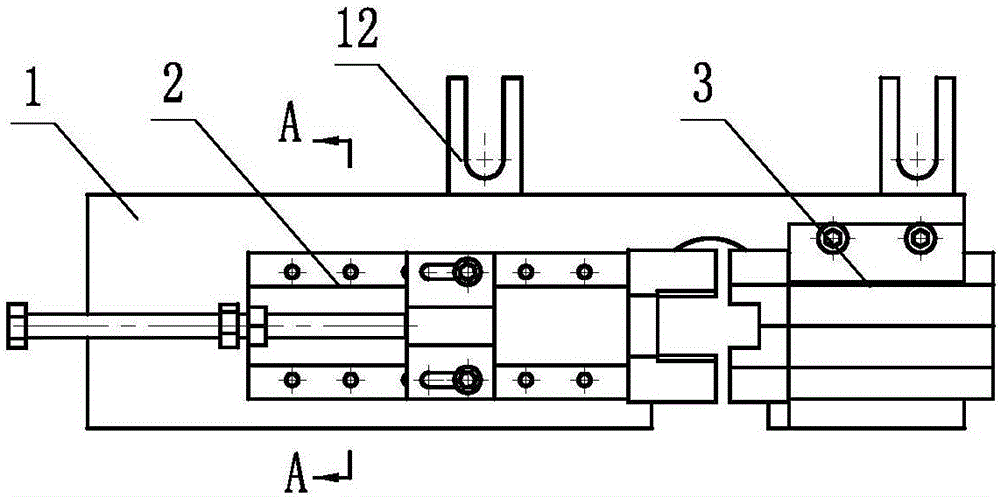

[0069] 1. A shock absorber limit ring seat spot welding device, characterized in that: the limit ring seat spot welding device comprises: a base plate 1 and a left positioning device 2 and a right clamping device 3 installed on the base plate,

[0070] One side of the bottom plate is connected with a U-shaped clamping block 12, and the other side of the bottom plate is provided with an electrode passing hole 11. The left positioning device 2 is installed on the bottom plate on the left side of the electrode passing hole, and the right clamping device 3 is installed on the On the bottom plate on the right side of the electrode passage hole, the left positioning device 2 and the right clamping device 3 are provided with a supporting station for the welding assembly of the connecting rod and the limit ring seat to be spot welded;

[0071] The left positioning device 2 includes a left support block 21, an adjustment slider 22, a limit ring seat positioning block 23 and an adjustmen...

Embodiment 2

[0080] A method for welding a limit ring seat of a shock absorber, which is a method of spot welding a connecting rod and a limit ring seat by using the spot welding device for a limit ring seat of a shock absorber described in Embodiment 1, comprising the following steps :

[0081] S1: Place the limit ring spot welding device on the workbench of the spot welder, so that the lower electrode of the spot welder passes through the electrode passage hole 11 from the bottom plate and faces the upper electrode, and connects with the U through the T-slot screw on the workbench. Type clamping block 12 connects and fastens the shock absorber limit ring seat spot welding device;

[0082] S2: Place the limit ring seat 51 in the groove opening 233 of the limit ring seat positioning block 23, and the limit ring seat flanging inner end surface 512 is close to the right end surface 234 of the limit ring seat positioning block;

[0083] S3: Place the connecting rod 52 on the V-shaped groove ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com