Glass fiber reinforced plastic cabin door sealing and mounting structure

A technology of installation structure and glass fiber reinforced plastics, which is applied in the direction of door device, transportation and packaging, building construction, etc., can solve the problems of poor sealing performance, heavy on-site workload, and non-existence, so as to improve sealing, reduce workload, and seal better effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

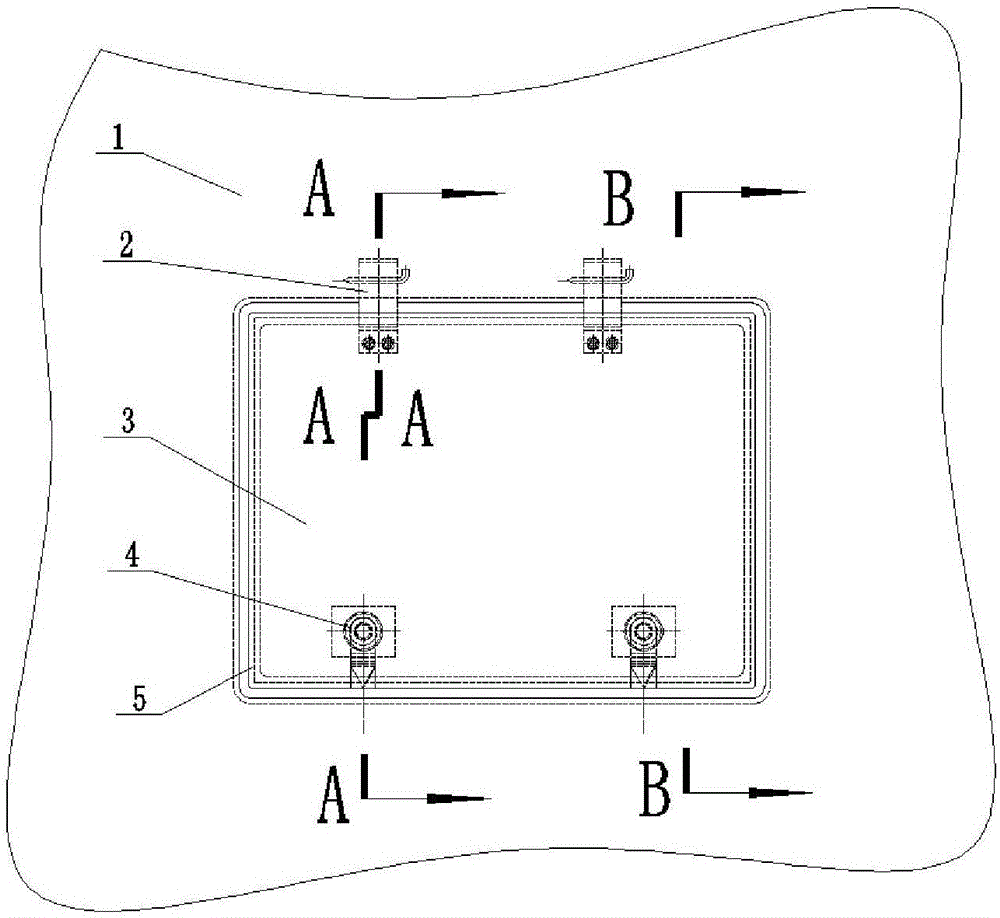

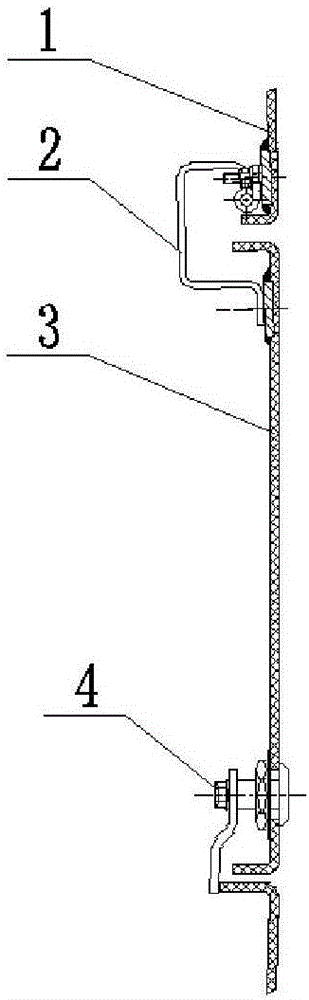

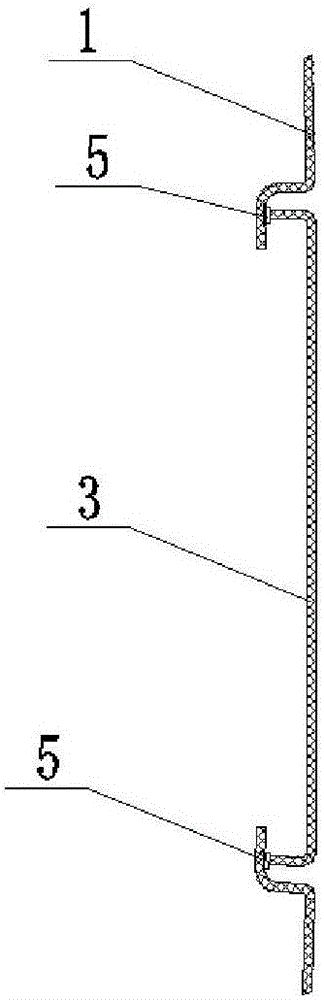

[0019] The present invention will be further described below in conjunction with accompanying drawing.

[0020] In order to improve the sealing performance of the cabin door 3, adjust the radius of rotation of the hinge 6, reduce the cutting amount of the FRP head 1 flanging; change the installation method and position of the sealing rubber strip 8, and change the installation method of the sealing rubber strip 8 by pasting Change the flange of the fiberglass head 1 to be inserted into the flange of the hatch 3 to ensure that when the hatch 3 is closed, the gap between the hatch 3 and the fiberglass head 1 is all filled by the sealant strip 8, greatly Improve sealing performance.

[0021] The compressed door lock 7 is used to replace the original rotary cam lock 4. The compressed door lock 7 has the ability to adjust the axial direction, which ensures that the size of the flange of the FRP head 1 does not need to be adjusted on site, and the workload on site is greatly reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com