Method for protecting battery stack during testing of vanadium battery

A testing process and technology of vanadium batteries, applied in the field of vanadium batteries, can solve the problems of high cost, burnout of vanadium battery stacks, etc., and achieve the effect of avoiding frequent on-off and simple process methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

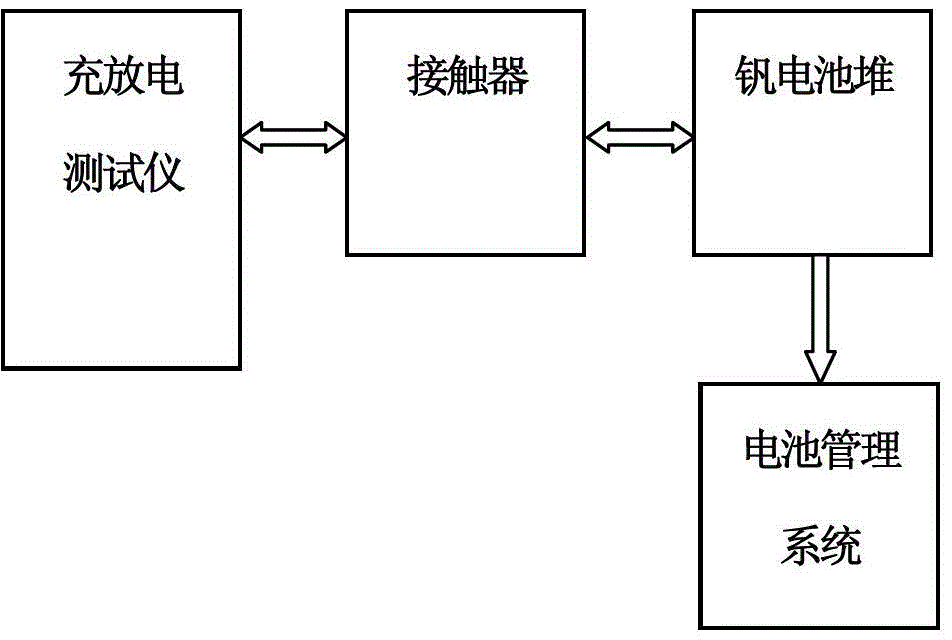

[0016] The vanadium battery management system detects that there is a fault on the vanadium battery side or the electrical part of the vanadium battery management system control cabinet and stops the circulation pump on the vanadium battery side. Since the vanadium battery management system and the charge and discharge tester work independently, if the charge The discharge tester still has the problem that charging the vanadium battery will damage the vanadium battery stack. Therefore, add a contactor between the charge and discharge tester and the vanadium battery. When the above situation occurs, the contactor will be disconnected by the battery management system.

[0017] When the vanadium battery management system detects a failure on the vanadium battery side or the electrical part of the vanadium battery management system control cabinet, it will stop the circulation pump on the vanadium battery side; at this time, the charge and discharge tester is still charging the van...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com