A device for measuring the temperature of cylinder seat oil

A cylinder block and oil technology, applied in the direction of measuring devices, thermometer parts, thermometers, etc., can solve the problem of not being able to directly detect the temperature of hydraulic oil in the cylinder block, and achieve no maintenance, meet temperature measurement requirements, and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

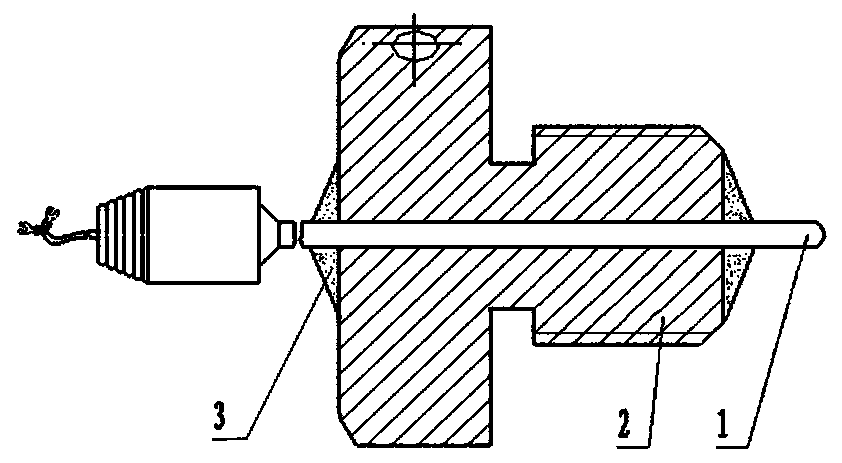

[0022] like Figure 1~4 shown. A device for measuring the oil temperature of a cylinder seat, comprising a thermocouple 1, a screw plug 2 and an adhesive 3. Among them, the thermocouple 1 is installed in the thermocouple installation hole at the center of the screw plug 2, and the lead-out wire end of the thermocouple is located outside the end face of the screw plug, and the temperature measuring head of the thermocouple is located at the other end of the screw plug. One end outside. The two ends of the screw plug 2 are sealed with an adhesive to seal the thermocouple.

[0023] The screw plug 2 is cylindrical. In the center of the screw plug, there is a thermocouple installation hole through longitudinally, which is used to place the thermocouple 1 . The screw plug is divided into a screw plug head section, a screw plug neck section and a screw plug rod section. The screw plug head section of the screw plug is located at one end of the screw plug, and is hexagonal outsid...

Embodiment 2

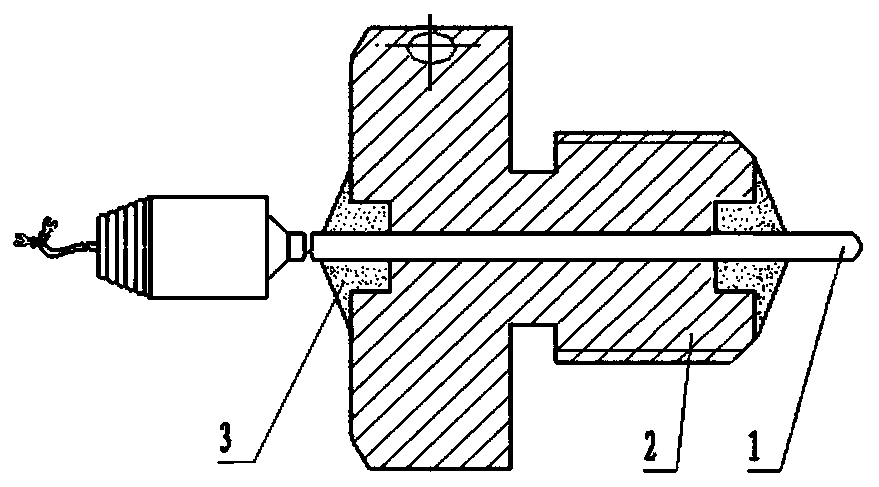

[0032] The difference between this embodiment and Example 1 is that the seal between the thermocouple 1 and the screw plug 2 is provided with a sealing device rubber sealing ring 4, and the sealing effect is better and more durable.

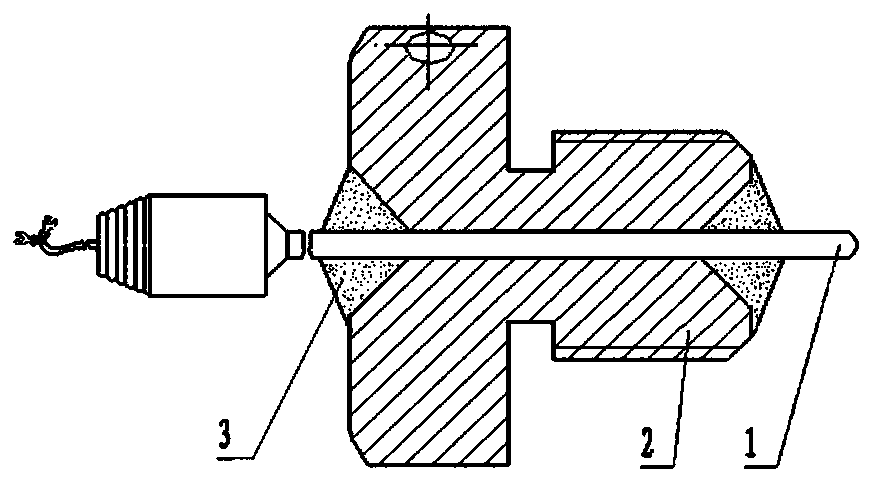

[0033] like Figure 5-7 shown. This embodiment includes a thermocouple 1 , a screw plug 2 and an adhesive 3 . Among them, the thermocouple 1 is installed in the thermocouple installation hole at the center of the screw plug 2, and the lead-out wire end of the thermocouple is located outside the end face of the screw plug, and the temperature measuring head of the thermocouple is located at the other end of the screw plug. One end outside. The two ends of the screw plug 2 are sealed with an adhesive to seal the thermocouple. Two or one sealing ring 4 is installed in the thermocouple mounting hole of the screw plug.

[0034] The screw plug 2 is cylindrical. In the center of the screw plug, there is a thermocouple installation hole through long...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compression ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com