A vacuum temperature field measuring device and measuring method

A measuring method and technology of measuring device, which are applied in the direction of measuring device, measuring heat, using electric device, etc., can solve the problems of loss, difficulty in making multi-point temperature measuring device, etc. The effect of temperature measurement requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

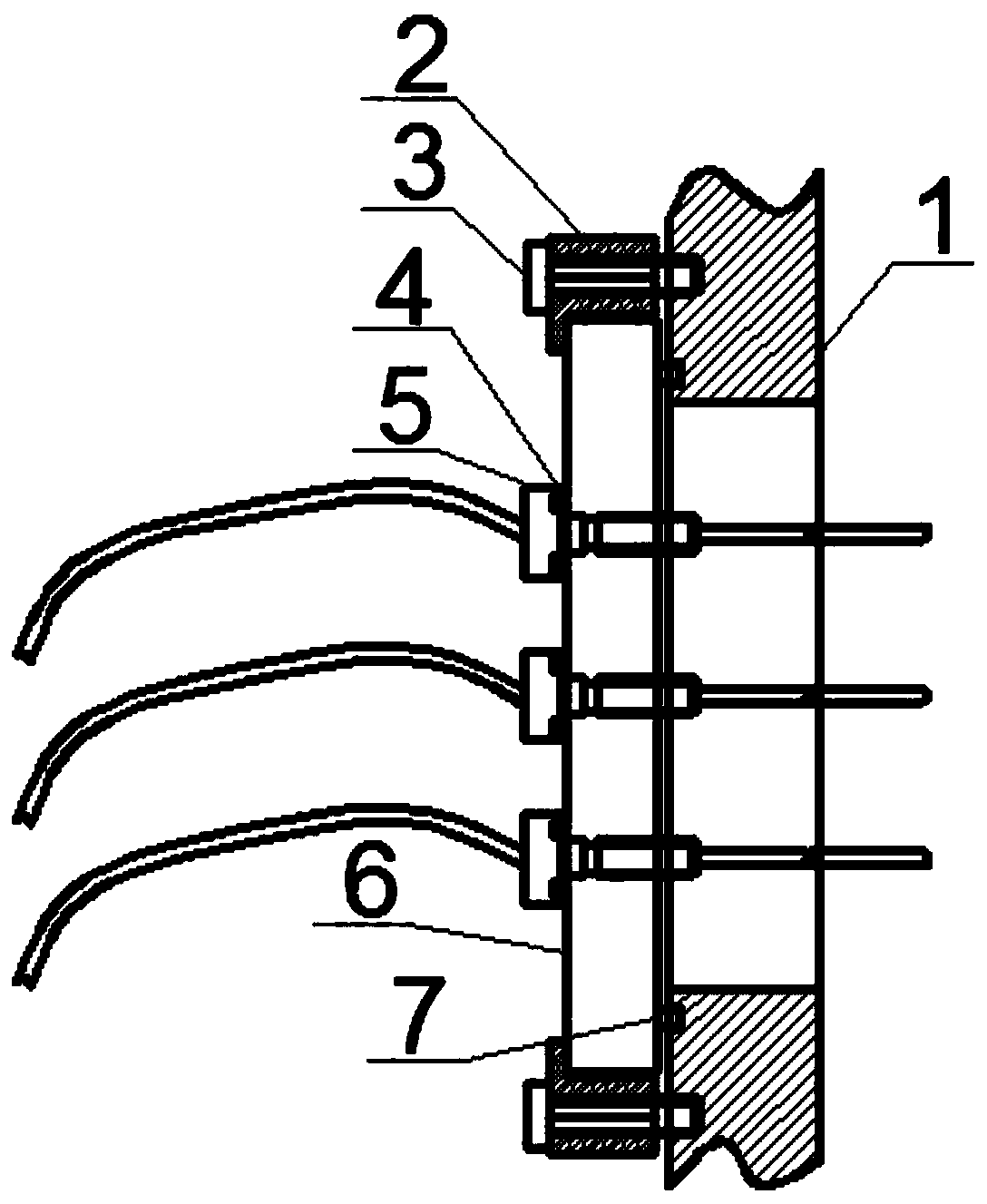

[0039] The technical solution of the present application will be further introduced in detail below in conjunction with the accompanying drawings of the description.

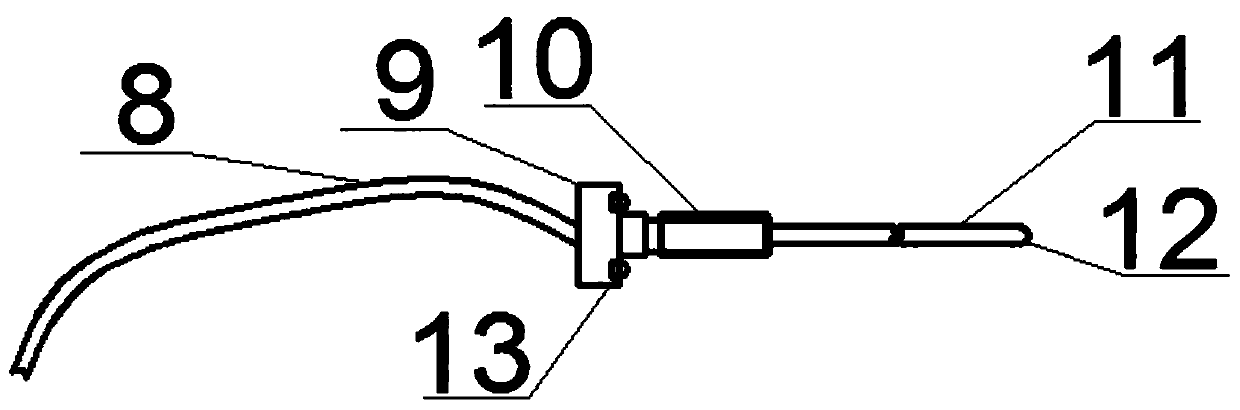

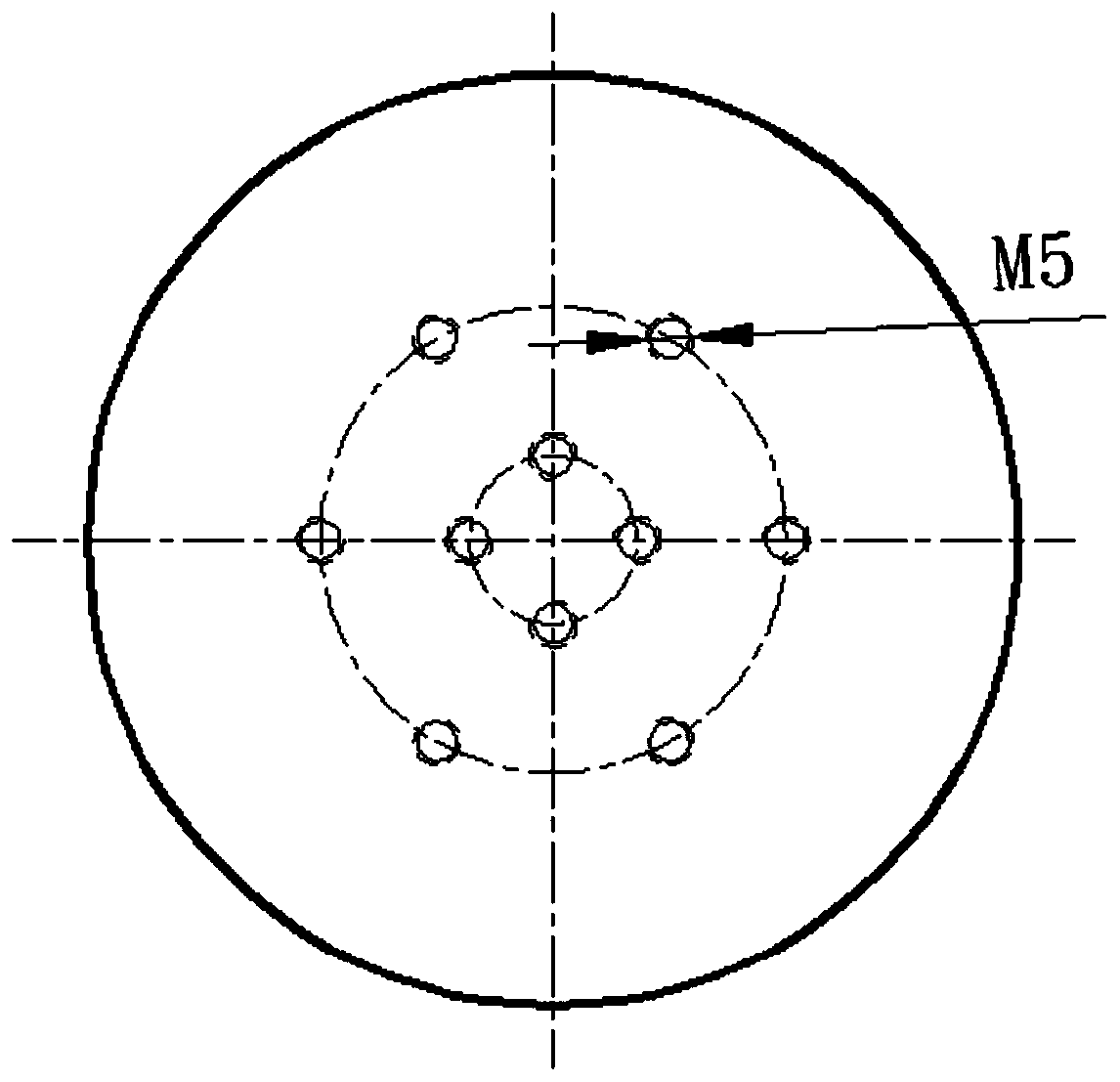

[0040] as attached image 3 It is a structural schematic diagram of a vacuum temperature field measuring device of the present application. The multi-point vacuum temperature field measuring device includes a plurality of temperature measuring thermocouples 5, thermocouple O-rings 4, flanges 6, flange pressure frames 2, Compression screw 3. The flange plate 6 matches the flange hole of the vacuum chamber of the vacuum equipment to be measured, and the flange plate 6 is provided with flange threaded holes corresponding to the number of temperature measuring thermocouples, and the temperature measuring thermocouples 5 are sequentially passed through the thermocouples. The screw thread on the outer surface of the lock nut 10 of the couple is screwed into the threaded hole of the flange, and the end 12 of the coupl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com