Cardan joint torque detection device

A detection device and universal joint technology, applied in the direction of measuring devices, force/torque/power measuring instruments, instruments, etc., can solve the problems of insufficient precision, complicated inspection process, low detection efficiency of production enterprises, etc., and achieve improvement Accuracy, ease of use, convenient detection process and efficient results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

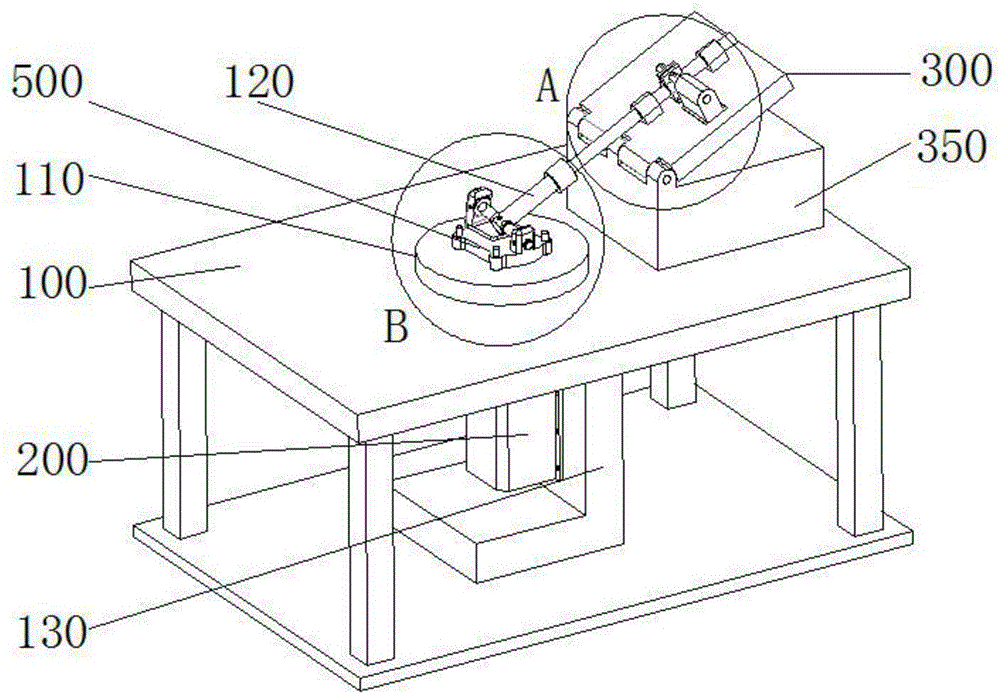

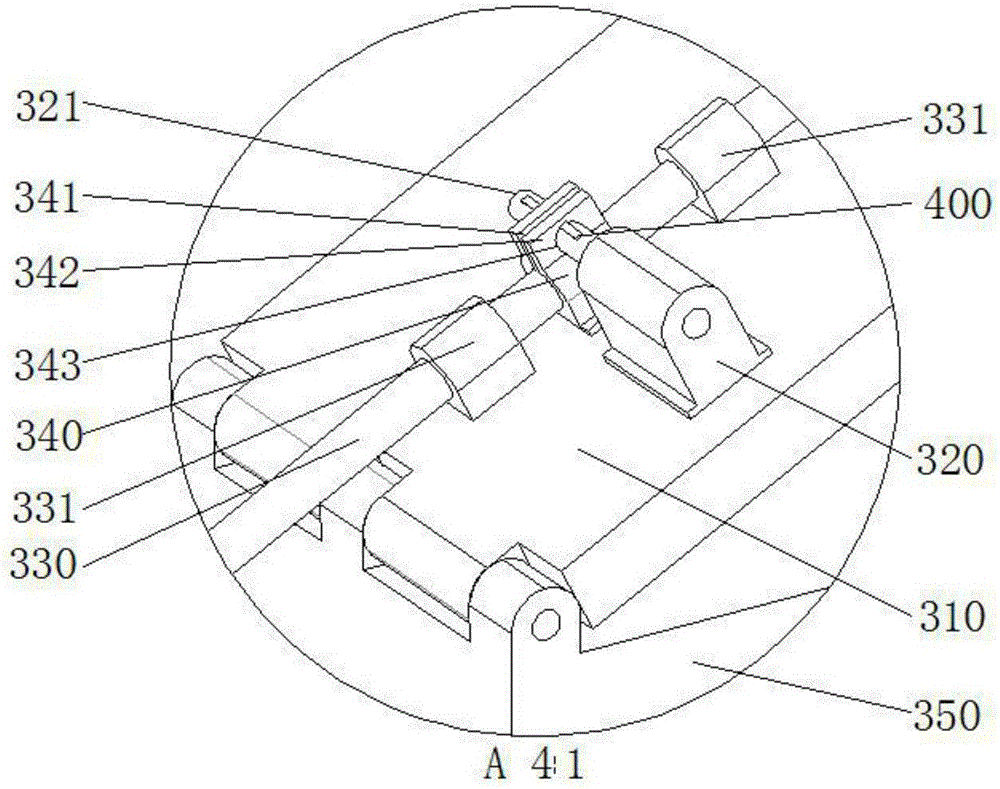

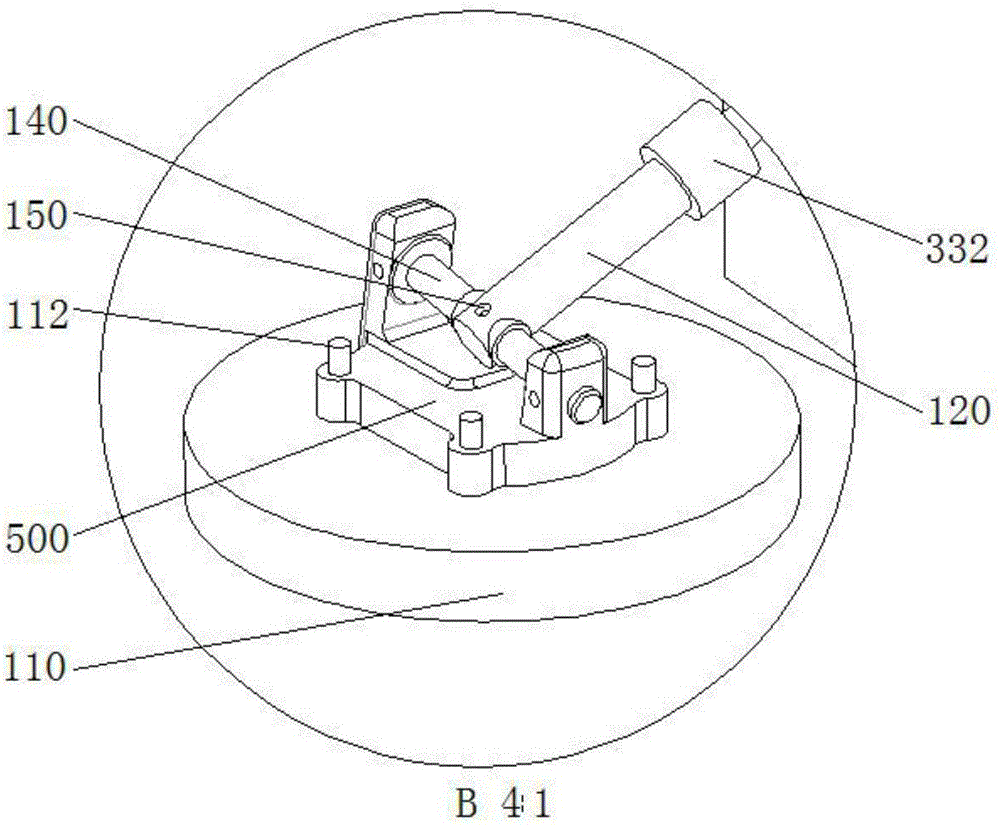

[0019] refer to figure 1 The universal joint torque detection device shown in -6 includes a torque motor 200, a workbench 100 on which the torque motor 200 is installed at the bottom, a torque measuring part 300 that is located on the workbench 100, and is used to connect the The torque motor shaft 210 of the torque motor 200 and the conversion joint 220 of the test piece 500, the rotating sleeve 110 provided on the workbench 100, and the connection for connecting the torque measurement component 300 and the test piece 500 Rod 120, and the sensor 400 located inside the torque measuring part 300, wherein the torque motor 200 is installed on the motor bracket 130 at the bottom of the workbench 100, and the torque measuring part 300 includes a mova...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com