Device for testing magnetic flux of magnetic component

A magnetic element and magnetic flux technology, applied in the direction of the size/direction of the magnetic field, can solve the problems of complex operation, interference, and low accuracy of test data, and achieve the effect of high test accuracy and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

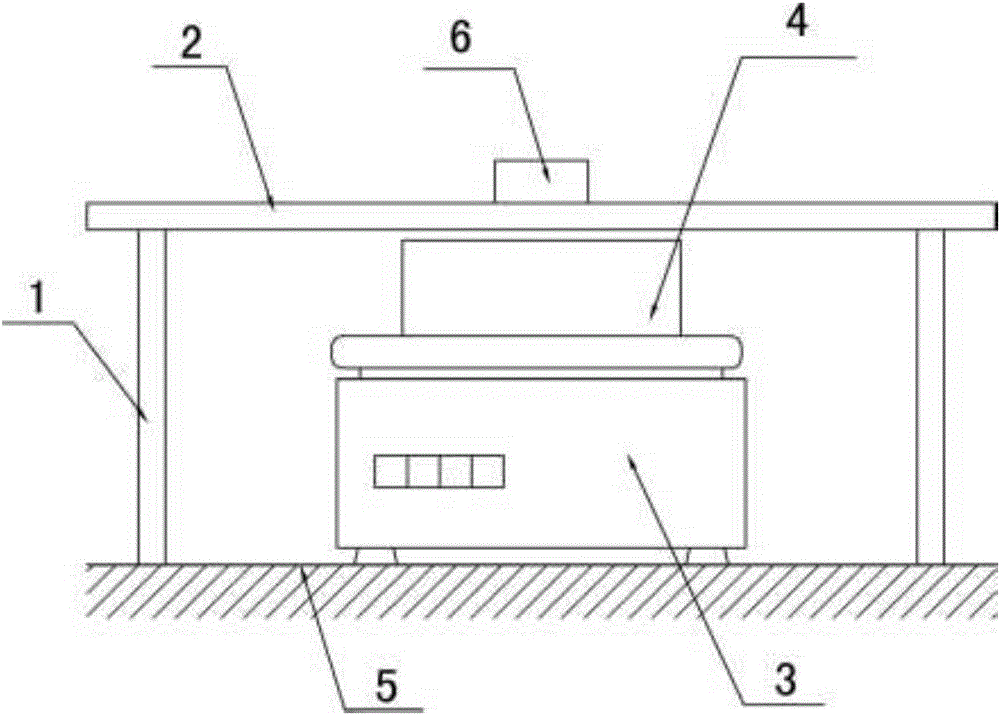

[0014] Embodiment: As shown in the figure, a device for detecting the magnetic flux of a magnetic element includes a support frame 1, a stage 2 fixed on the support frame 1, an electronic scale 3 and an iron block 4 located directly below the stage 2, The stage 2 is made of non-magnetic material stainless steel, the upper surface and the lower surface of the stage 2 are both horizontal planes, the iron block 4 is placed on the electronic scale 3, and the upper surface and the lower surface of the iron block 4 are both horizontal planes , there is a gap between the upper surface of the iron block 4 and the lower surface of the stage 2 .

[0015] In this embodiment, the thickness of the stage 2 is 3 mm, and the gap between the upper surface of the iron block 4 and the lower surface of the stage 2 is 10 mm.

[0016] In this embodiment, both the upper surface and the lower surface of the stage 2 are polished, and the upper surface and the lower surface of the iron block 4 are both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com