Exploiting-following wireless intelligent spraying dustfall control system for mines

A spray dust reduction and wireless technology, applied in dust prevention, mining equipment, mining equipment, etc., can solve the problems of difficult cable layout, complex underground environment, complex maintenance, etc., to prevent workers from getting wet, improve coal dust environment, Easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

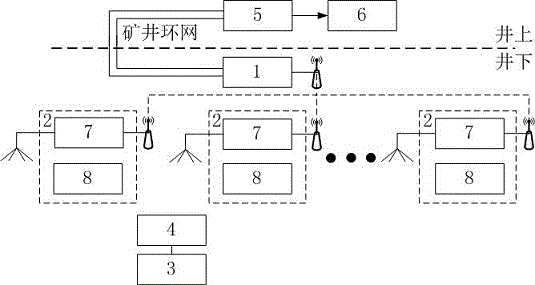

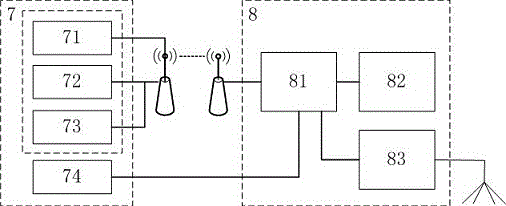

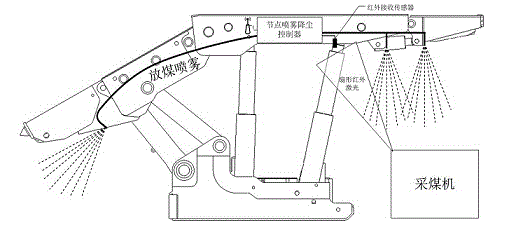

[0041] In order to further explain the technical means and effects of the invention in order to achieve the invention and achieve the intended purpose of the invention, the following is combined with the accompanying drawings and preferred embodiments to describe the specific implementation of the wireless intelligent spray dust suppression control system for mining according to the present invention. , structure, feature and effect thereof, detailed description is as follows.

[0042]The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of the preferred examples with reference to the drawings. Through the description of the specific implementation, the technical means and effects of the present invention to achieve the intended purpose can be understood more deeply and specifically, but the attached drawings are only for reference and description, and are not used to limit ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com