Core head forming method of manual core making

A core head, manual technology, applied in the direction of cores, mold components, manufacturing tools, etc., can solve the problems affecting the positioning of the sand core, the supporting function, and the difficulty of forming the core head, so as to shorten the trial production period and facilitate the core making. , the effect of reducing the cost of trial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

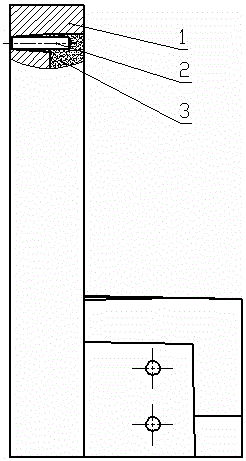

[0010] figure 1 Among them, the present invention includes a core box 1, and the bodies of the core boxes 1 are positioned with positioning pins or notches (small core boxes are manually fixed, and large core boxes are fastened with clamps). When making cores by hand, first place the core forming metal rod 2 at the core hole of the core box 1, and require that one end face of the core forming metal rod 2 be flush with the bottom end surface of the core box 1 core hole (from the core forming Metal rod 2 positioning function), the other end of the core forming metal rod 2 enters the cavity of the core box 1, and then manually fills the core sand 3 into the core box 1, and then manually or with a wooden hammer to compact the core sand for core making. After the core making is completed, the sand core with the core forming metal rod 2 is baked, the core forming metal rod 2 is solidified in the sand core, and the core forming rod plays the role of positioning and supporting the san...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com