A gasification production method of high calorific value synthesis gas and a device for realizing the method

A production method and technology of a gasification device, applied in the field of gasification production methods and devices for realizing the method, can solve the problems of energy consumption, large energy consumption of milling, and large production scale, so as to reduce the height of the system and reduce the production cost , the effect of increasing the calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

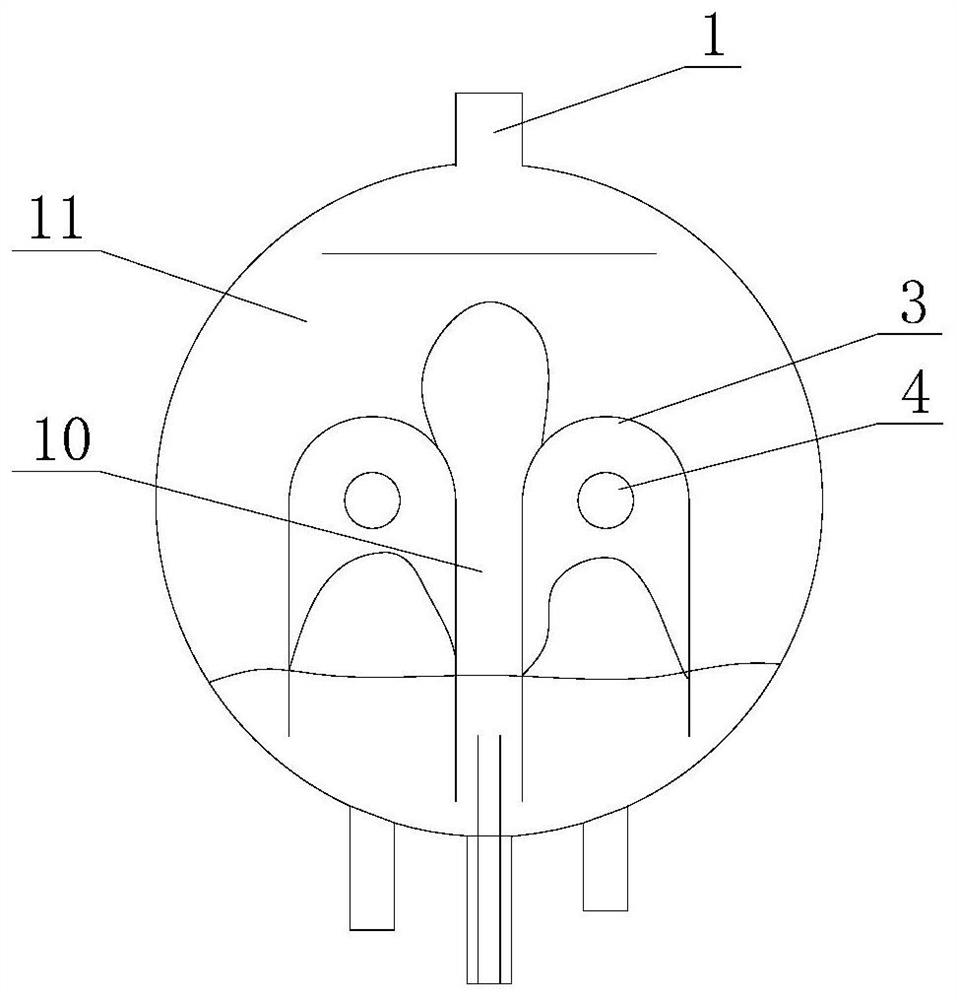

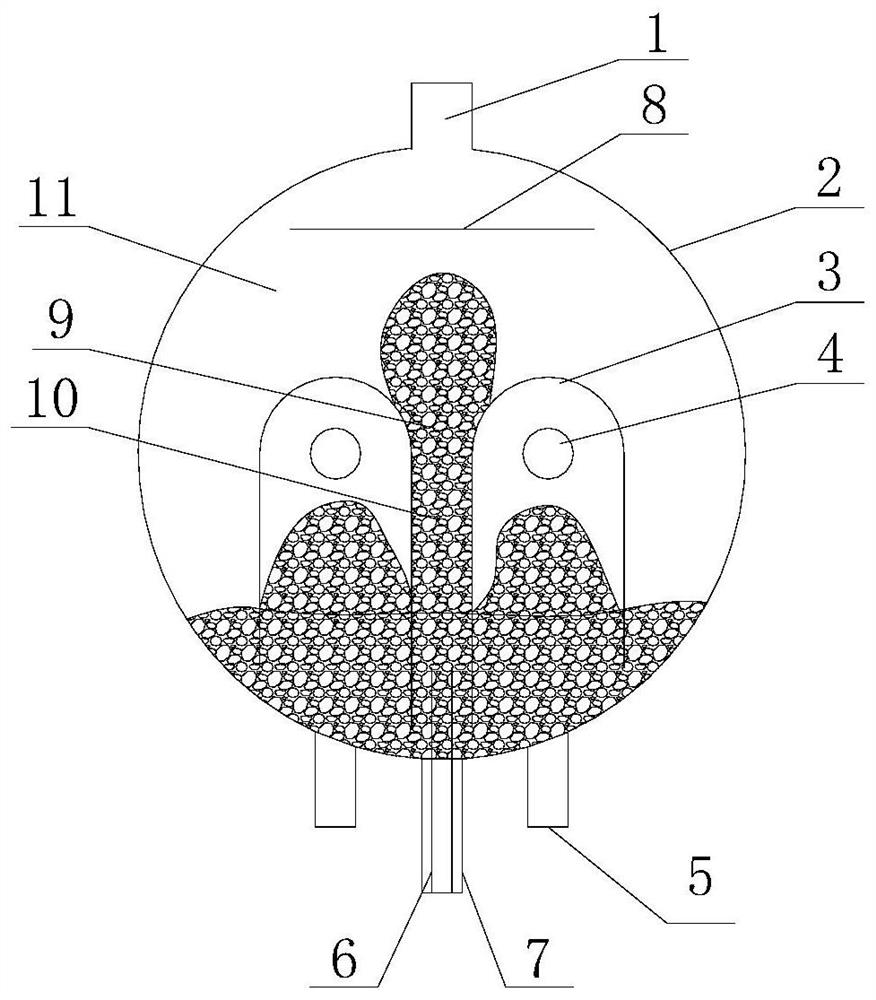

[0037] A device for realizing the gasification production method of high calorific value syngas, comprising a horizontal gasification device cylinder 2, a fluidization gasification chamber 10 arranged in the middle of the horizontal gasification device cylinder 2 and a fluidization gasification chamber 10 arranged in the middle of the horizontal gasification device cylinder 2 The gasification circulation chamber 11 on the upper part of the chamber 10, the fluidization gasification chamber 10 communicates with the bubbling combustion chamber 3, the bubbling combustion chamber 3 communicates with the gasification circulation chamber 11, and the bubbling combustion chamber 3 and the gasification circulation chamber 11 pass coal particles Separated to prevent the flue gas in the bubbling combustion chamber 3 from entering the fluidization gasification chamber 10 and the gasification circulation chamber 11 during the combustion process. The steam pipe 6 and the preheated air pipe 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com