Wafer Preparation Method for Improving Wafer Strength and Backside Metal-Silicon Adhesion Strength

A backside metal and adhesion strength technology, which is applied in chemical instruments and methods, crystal growth, semiconductor/solid-state device manufacturing, etc., can solve the problems of insufficient wafer strength, poor backside metal adhesion strength, and metal loss, etc., to reduce Insufficient chip strength, improved metal adhesion, and the effect of solving insufficient wafer strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

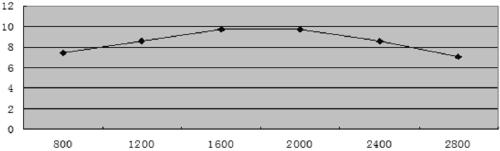

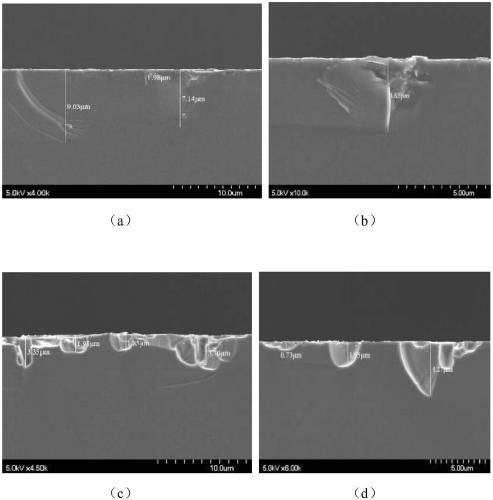

[0013] Specific implementation mode 1. Combination figure 1 Describe this embodiment mode, the wafer preparation method that improves wafer strength and backside metal and silicon adhesion strength, and this method is realized by the following steps:

[0014] Step 1. After thinning, use the sandblasting process (sandblasting only requires the number of turns, no thickness requirement) to perform backside sandblasting to improve the roughness of the backside, thereby improving the adhesion between the backside metal and the chip;

[0015] Place the basket of chips to be prepared on the operating table, use a sandblasting machine to sandblast 2 circles, take out the chip and place it in a small sink filled with deionized water, rinse with water for 15 minutes, and dry it for 15 minutes to complete the sandblasting operate.

[0016] Step 2. Use the concentrated acid etching process to reduce the strength of the chip after the silicon etching solution on the back; the specific ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com