floor drain

A floor drain and body technology, applied in waterway systems, buildings, water supply devices, etc., can solve the problems of heavy floor drain, high cost, easy to scratch users, etc., to accelerate the flow of water, reduce the possibility, and improve the ability to grip the ground. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

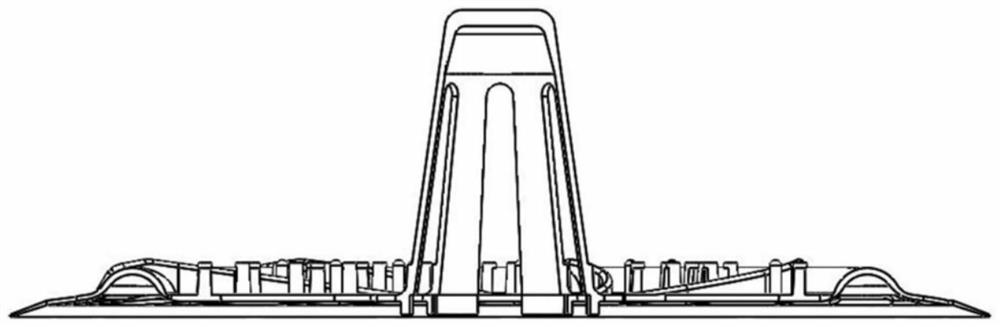

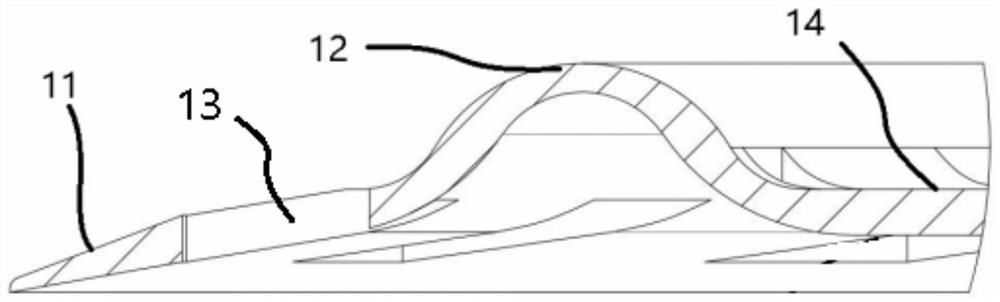

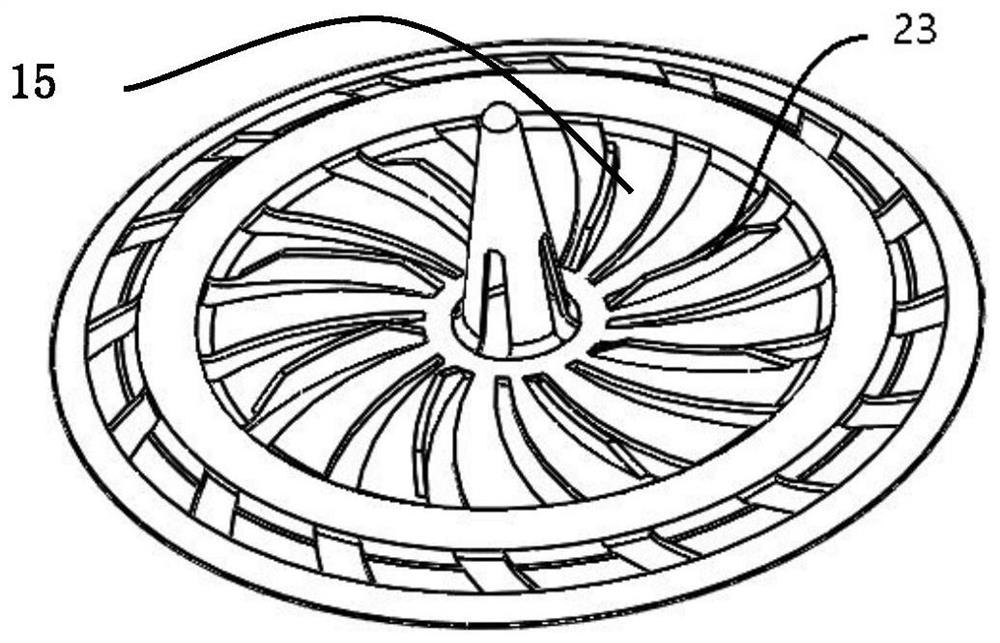

[0034] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, the floor drain includes a floor drain body, which is characterized in that: the floor drain body is sequentially composed of an edge portion 11, a first raised portion 12, and a floor drain panel 14 from the outside to the center, and the floor drain panel is provided with at least one first floor drain hole 15 . The upward convex part is set at the adjacent position of the edge of the floor drain, which can make the water flow into the center of the floor drain to cause climbing phenomenon, increase the gripping ability of the floor drain, improve the ability to resist the impact of water flow, and make the floor drain place stable.

[0035] More preferably, the level of the floor drain panel 14 is higher than the level at which the edge portion 11 contacts the ground. The floor drain panel 14 is higher than the edge and grounded, so that after the water flow flows into the panel, the large...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com