Symmetrically-arranged closed gear transmission system

A technology of gear transmission and symmetrical arrangement, which is applied in the direction of gear transmission, transmission, transmission parts, etc., can solve the problems of unstable center of gravity, easy to sway, unsafe use, etc., and achieve stable center of gravity, not easy to sway, The effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

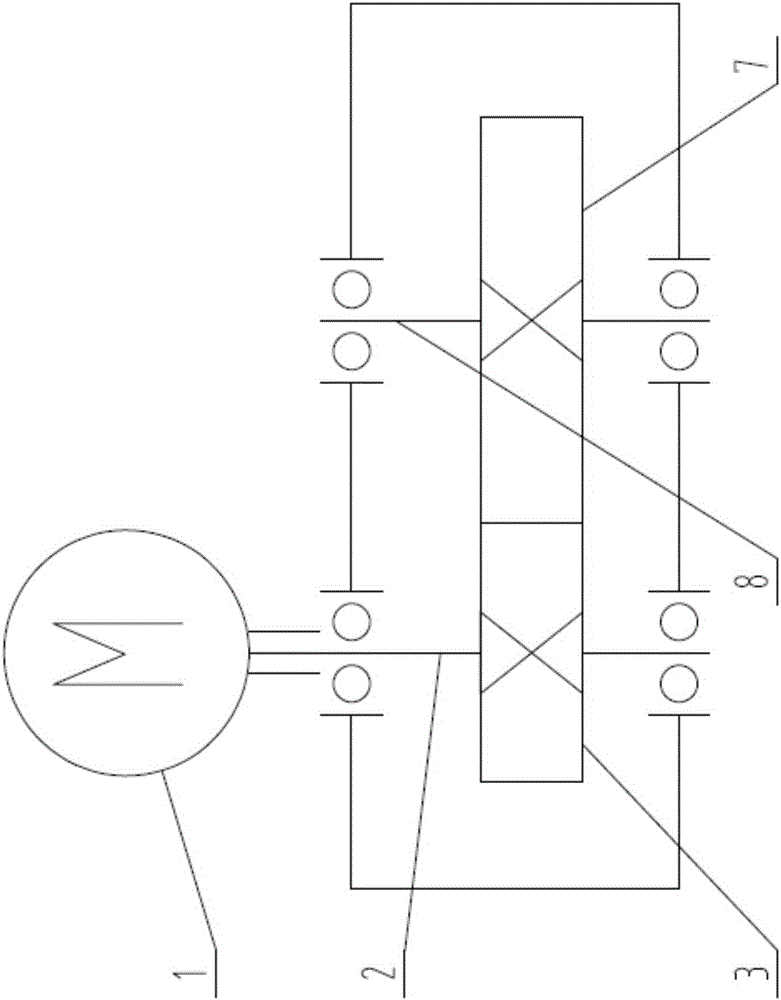

Embodiment 1

[0016] like image 3 As shown, a symmetrically arranged closed gear transmission system includes a power source 1, an input shaft 2, an input gear 3, an output gear 7, and an output shaft 8. The power source 1 is connected to the input shaft 2, and the input gear 3 On the shaft 2, the output gear 7 is on the output shaft 8 and is externally meshed with the input gear 3. The gear transmission system is symmetrical along the output shaft 8, and the two power sources 1 have the same power, the same rotation direction and output power synchronously. When working, the two power sources 1 output power, through the input shaft 2 and input gear 3 on both sides, the power is transmitted to the corresponding output gear 7 for speed change, and finally the output shaft 8 outputs the power of the speed change. At this time, the output speed is the same as that of the power source The speed difference is small.

Embodiment 2

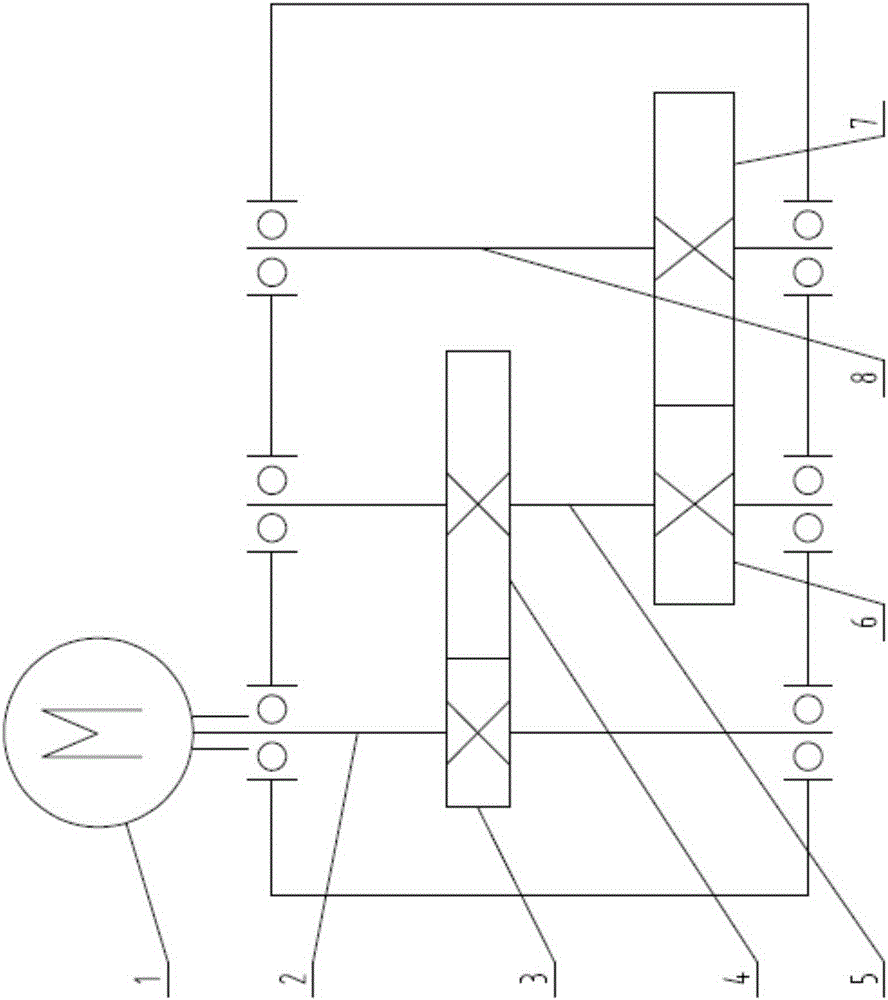

[0018] like Figure 4 As shown, a symmetrically arranged closed gear transmission system includes a power source 1, an input shaft 2, an input gear 3, a transmission gear A4, a transmission shaft 5, a transmission gear B6, an output gear 7 and an output shaft 8; the power source 1 is connected to the input shaft 2, the input gear 3 is on the input shaft 2, the speed change gear A4 and the speed change gear B6 are connected in series on the speed change shaft 5, and the output gear 7 is on the output shaft 8; the input gear 3 is externally meshed with the speed change gear A4 , the transmission gear B6 is externally meshed with the output gear 7; the gear transmission system is symmetrical along the output shaft 8, and the two power sources 1 have the same power, the same rotation direction and synchronous output power. When working, the two power sources 1 output power, and the power is transmitted to the corresponding speed change gear A4 through the input shaft 2 and the inp...

Embodiment 3

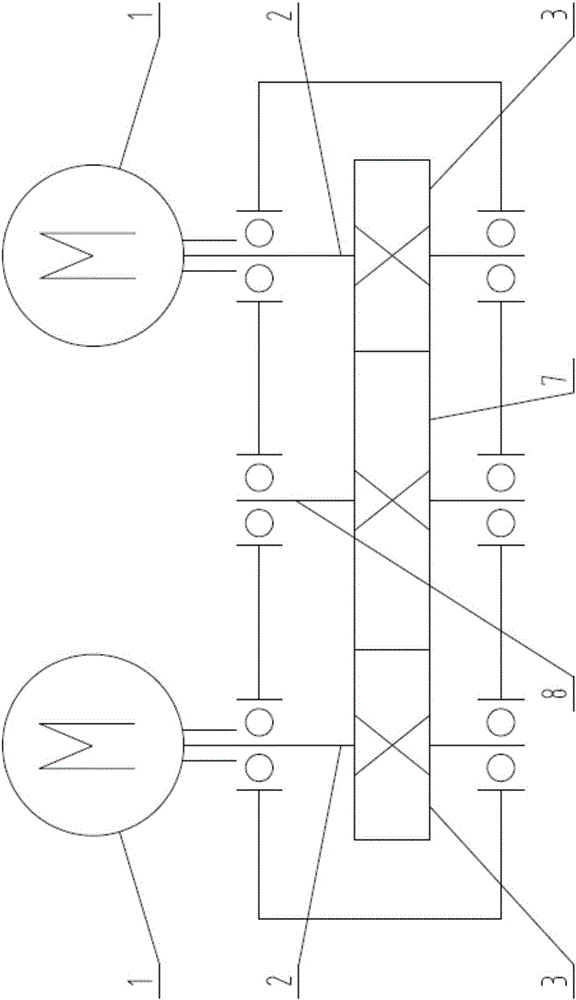

[0020] A symmetrically arranged closed gear transmission system, including a power source 1, an input shaft 2, an input gear 3, a transmission gear A4, a transmission shaft 5, a transmission gear B6, a transmission gear C, a transmission shaft, a transmission gear D, an output gear 7 and Output shaft 8; the power source 1 is connected to the input shaft 2, the input gear 3 is on the input shaft 2, the speed change gear A4 and the speed change gear B6 are connected in series on the speed change shaft 5, and the speed change gear C and the speed change gear D are connected in series on the speed change shaft , the output gear 7 is on the output shaft 8; the input gear 3 is externally meshed with the speed change gear A4, the speed change gear B6 is externally meshed with the speed change gear C, and the speed change gear D is externally meshed with the output gear 7; the gear transmission system is along the output shaft 8-axis symmetry, the two power sources 1 have the same powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com