A Mechanical Structure of a Refracted Optical System

A technology of optical system and mechanical structure, applied in the direction of optics, optical components, instruments, etc., can solve the problems of system wavefront variation and difficulty in guaranteeing, and achieve the effects of improving precision, quickly removing glue, and simplifying the bonding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

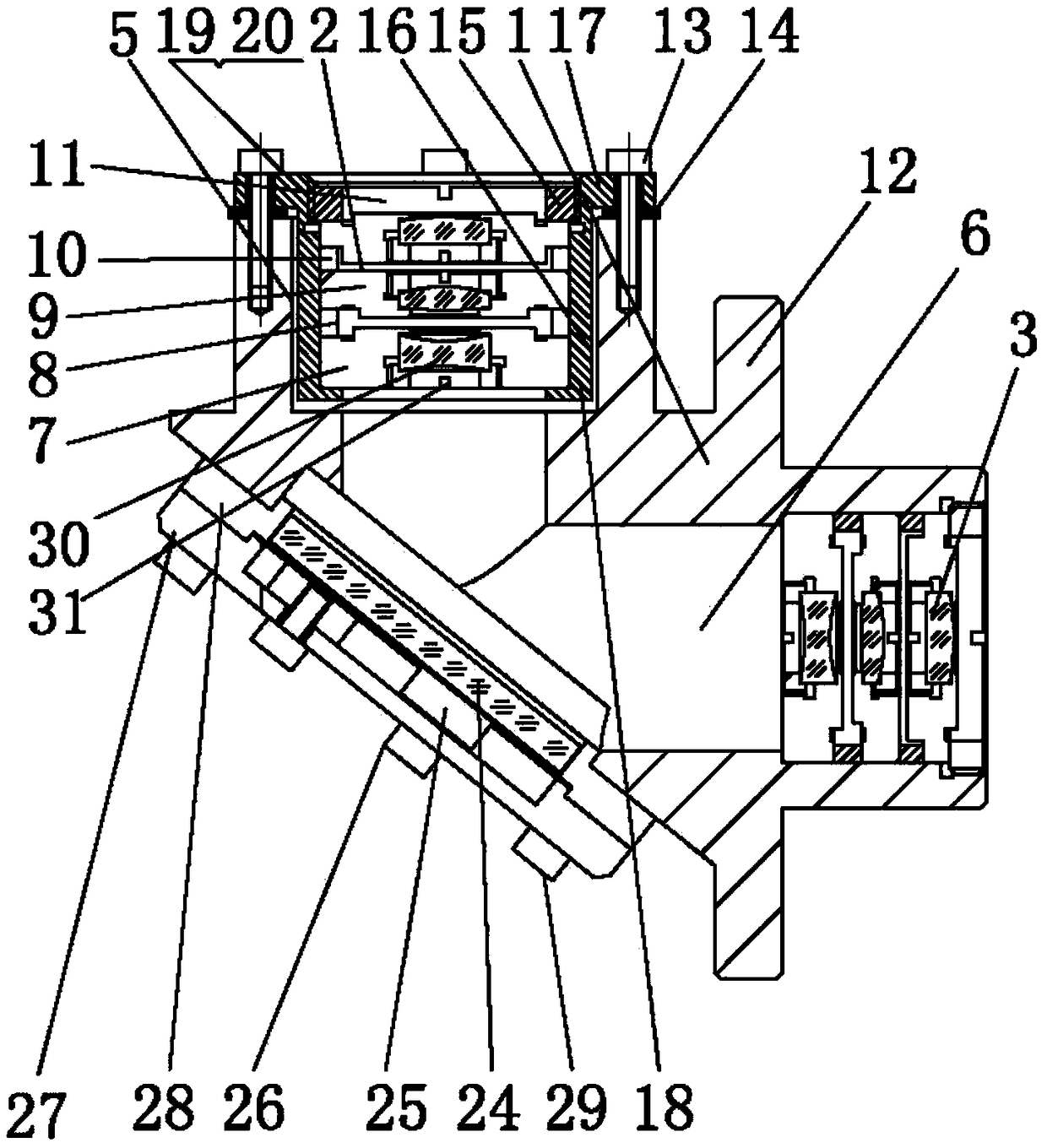

[0024] see Figure 1-4 , a mechanical structure of a folded light path optical system includes a folded mirror frame 1, a front mirror group 2, a rear mirror group 3 and a plane mirror group;

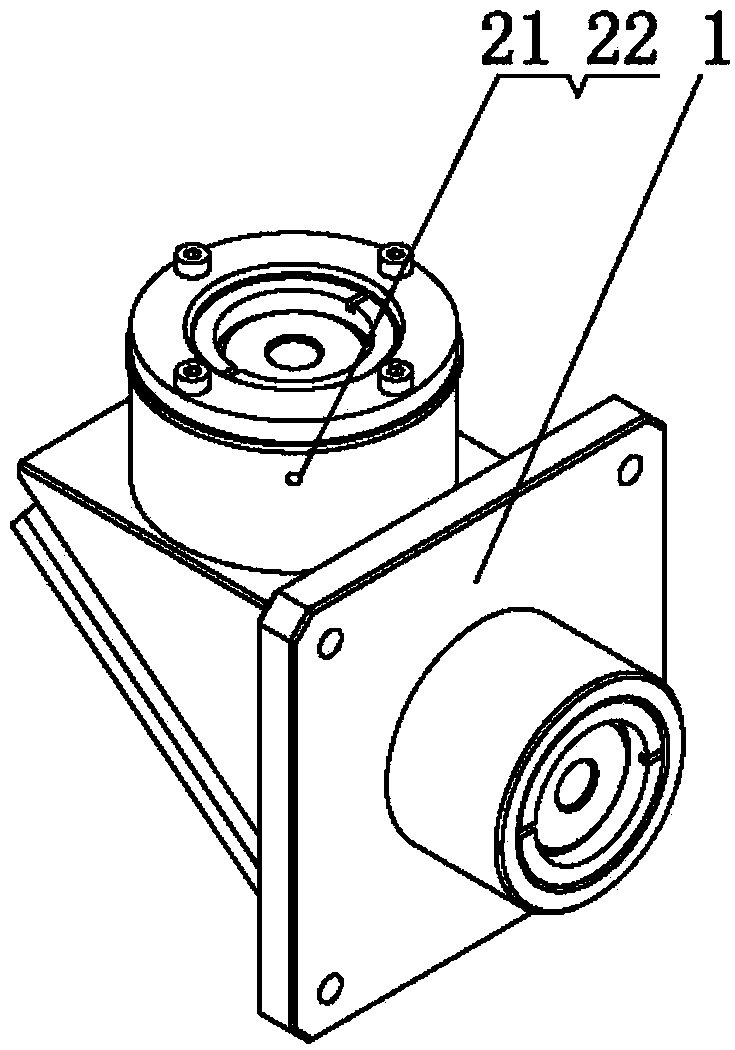

[0025] Folding mirror frame 1 is formed by the intersection of the vertical lens barrel 5 arranged vertically and the horizontal lens barrel 6 arranged horizontally, and the plane mirror group is installed in the intersection of vertical lens barrel 5 and horizontal lens barrel 6; The central axis of lens barrel 5 and horizontal lens barrel 6 is coplanar and its intersection point is on the mirror surface of plane mirror group;

[0026] The front lens group 2 is installed in the vertical lens barrel 5; the rear lens group 3 is installed in the horizontal lens barrel 6;

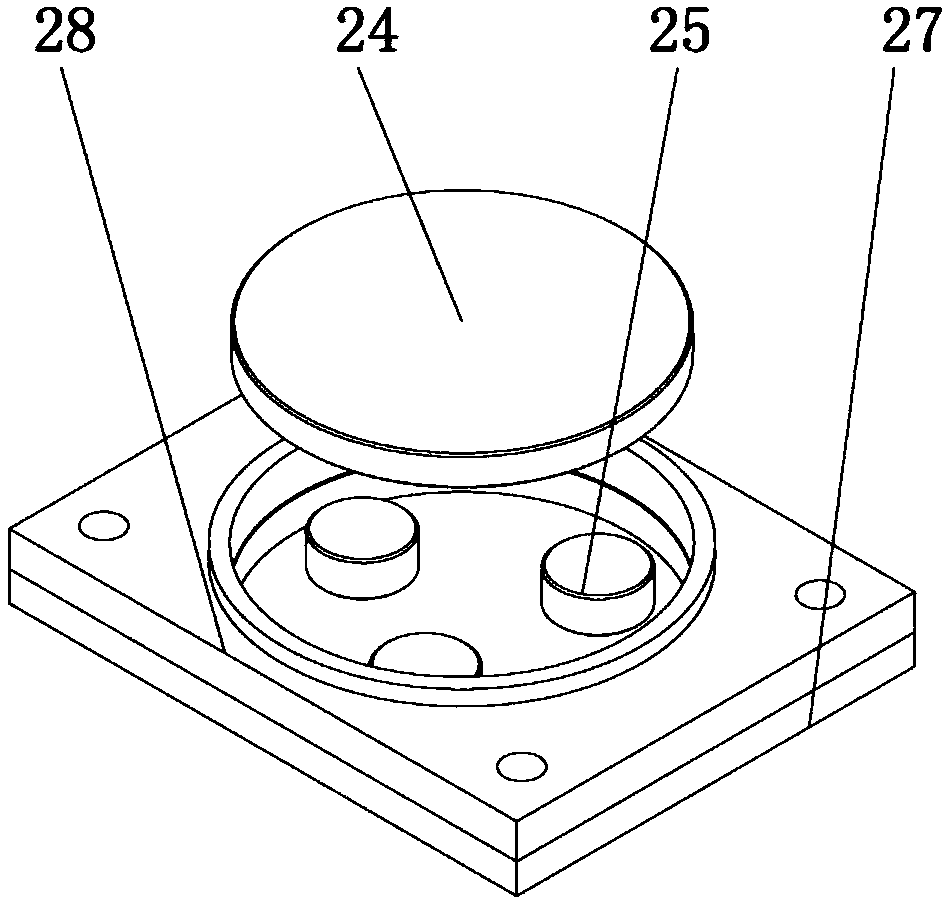

[0027] The front mirror group 2 includes at least one mirror group, which is composed of three mirror groups here; specifically: the first front mirror group 7, the first front spacer 8, the second front mirror group i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com