I/O port circuit structure with hot plug function

A port circuit, hot-swap technology, applied in logic circuits, logic circuit coupling/interface using field effect transistors, logic circuit connection/interface layout, etc., can solve the problems of system voltage drop, system large, system capacitor discharge and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

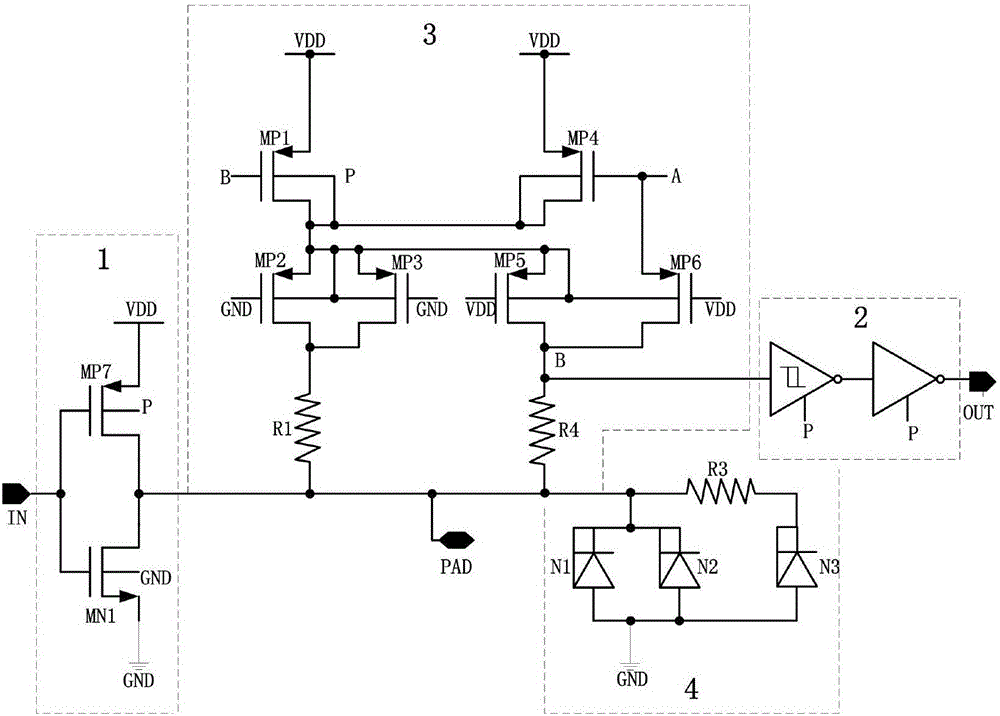

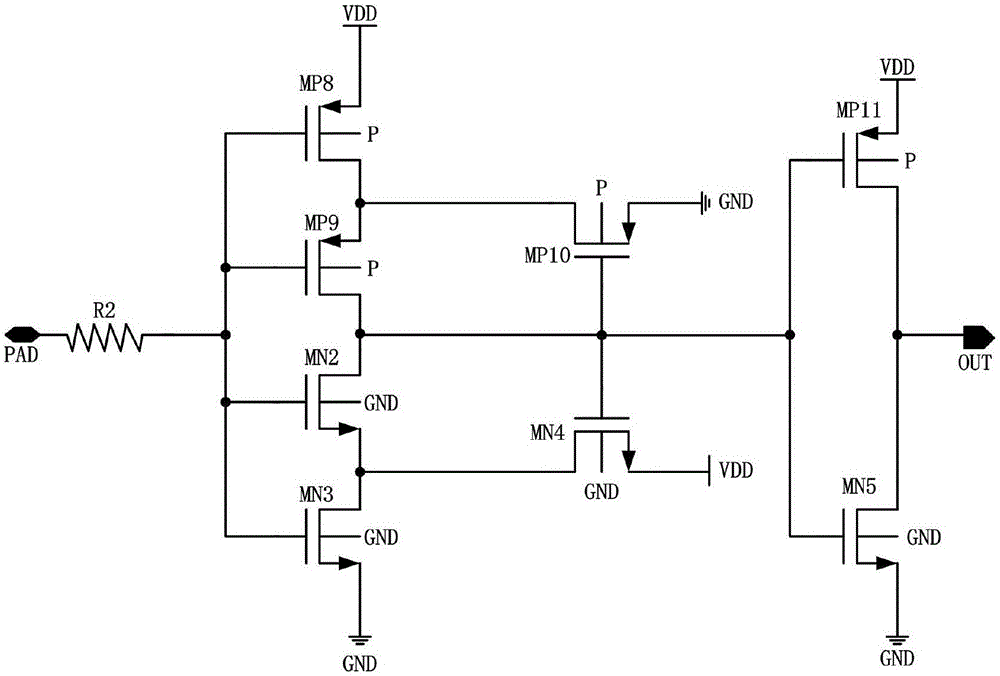

[0021] Such as figure 1 As shown, an I / O port circuit structure with hot swap function includes four main modules, namely an output buffer module 1 , an input buffer module 2 , a hot swap module 3 , and an ESD protection module 4 . The output buffer module 1 is connected to the PAD terminal, the input signal, and the input and output selection control terminal, and is used to realize the function of the port PAD as the output terminal; the input buffer module 2 is connected to the PAD terminal and the output signal, and is used to realize the function of the port PAD as the input terminal; The pull-out module 3 is connected to the PAD end through a resistor to realize the plug-in function; the ESD protection module 4 is connected to the PAD end to realize the 2000V ESD protection capability.

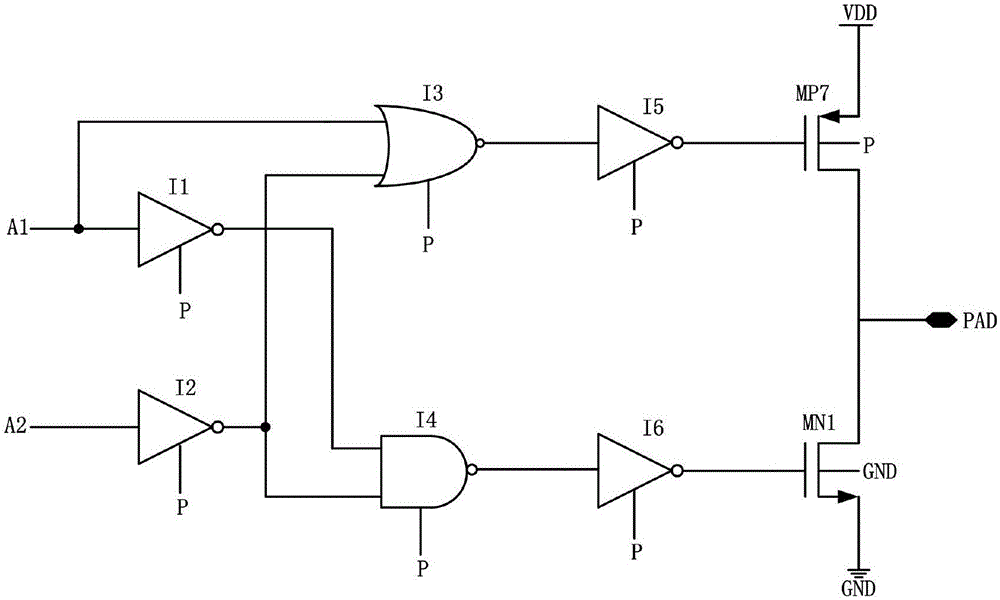

[0022] The output buffer module 1 in this structure is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com