Through-bus card-connected ultra-large load capacity ring wiring with high reliability pdu

A load capacity, busbar card technology, applied in the connection, the parts of the connection device, the board/panel/desk of the substation/switchgear, etc., can solve the problem that the output port is not compatible with sockets and wires with plugs, and the efficiency of full manual production and assembly Low, difficult to guarantee quality consistency, etc., to achieve the effect of eliminating single-point failure power outages, saving effective cabinet space, and eliminating the risk of fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments.

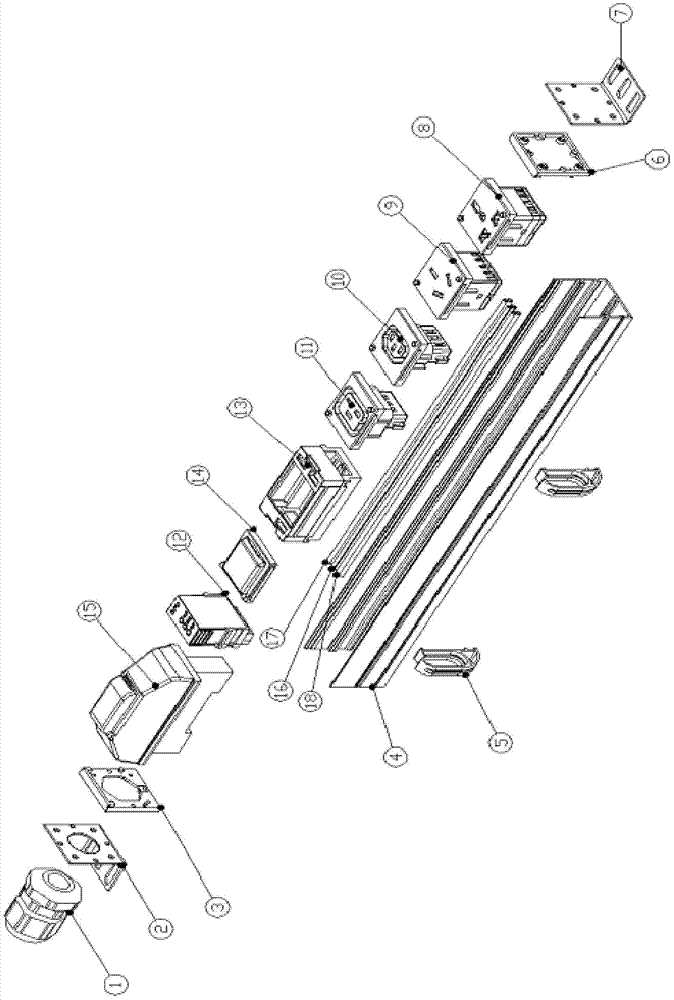

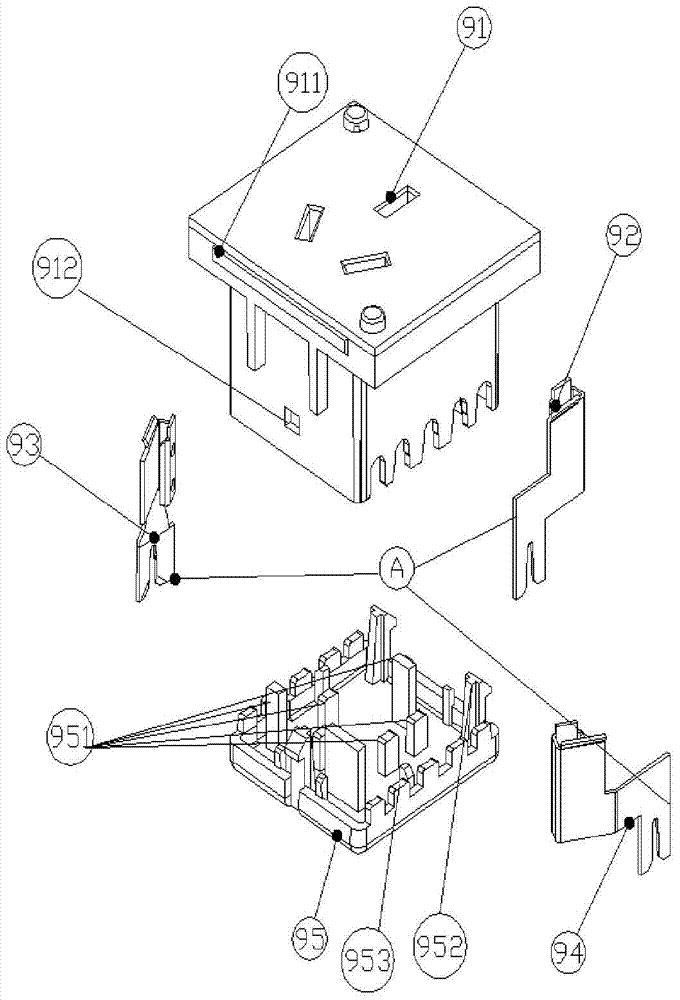

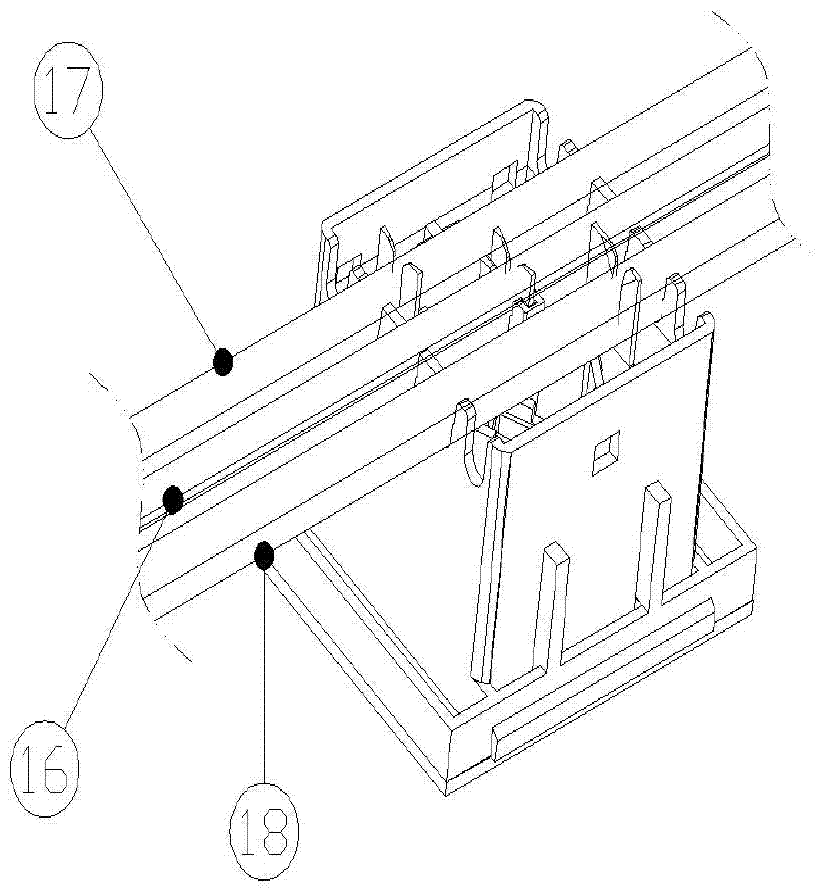

[0069] Such as figure 1 , 20 As shown in 23, the high-reliability PDU with super-large load-capacity annular wiring through bus bar clamping includes waterproof terminal 1, incoming line installation end plate 2, incoming line insulating end plate 3, housing 4, cable organizer 5, insulation End plate 6, installation end plate 7, universal module 8, GB-10A module 9, IEC-C13 module 10, IEC-C19 module 11, SPD module 12, monitoring module 13, zero fire double break Switch 14, Circuit Breaker 15, Bus-PE 16, Bus-L17 and Bus-N18.

[0070] shell

[0071] Such as Figure 5 As shown, the housing 4 is an "凵"-shaped groove, including an end plate mounting beam 41 and a chute 42 axially penetrating the housing 4; The middle position of the lower wall of the shell 4, and the end plate mounting beam 41 axially penetrates the shell 4; universal socket mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com