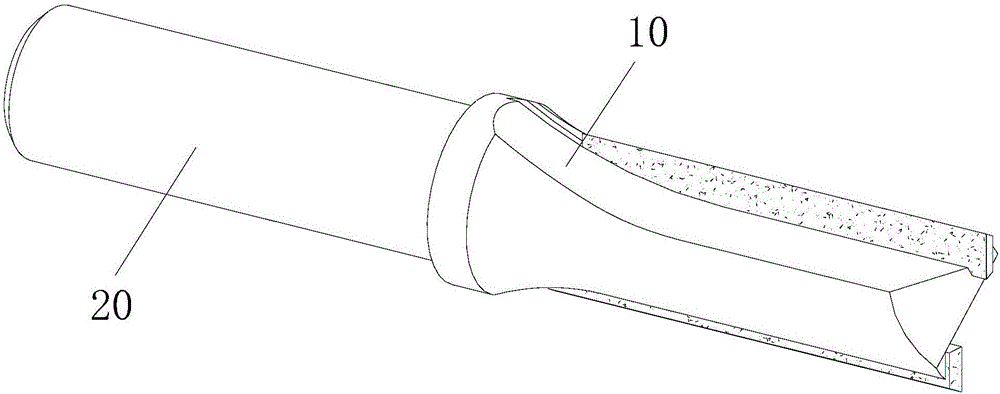

Improved wood product machining straight knife

A technology of wood products and straight knives, applied in wood processing equipment, manufacturing tools, wood drilling tools, etc., can solve the problems of long processing time, increased production costs, large material loss, etc., achieve flexible use of knives, and reduce raw material costs , the effect of high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solutions of the present invention will be further described in detail below in conjunction with specific embodiments, but this does not constitute any limitation to the present invention.

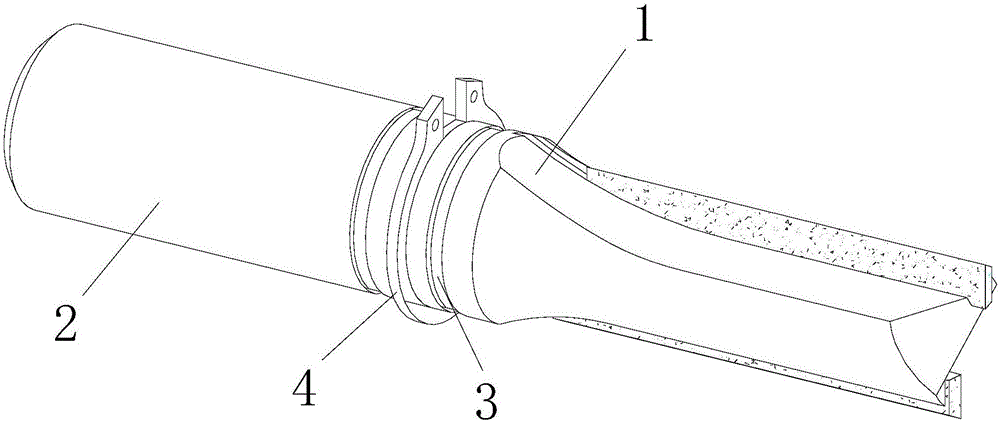

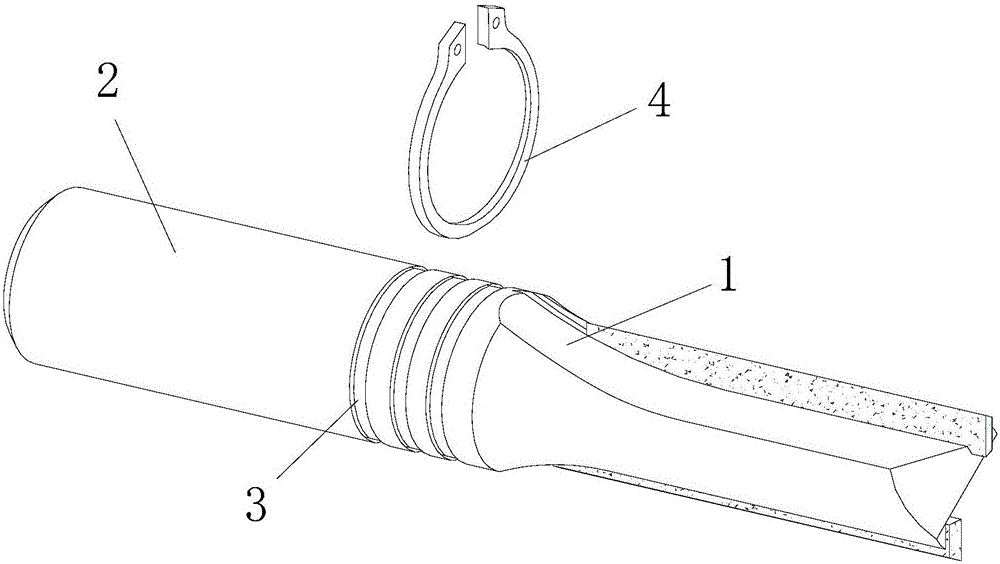

[0015] refer to figure 2 and image 3 As shown, an improved straight knife for processing wood products of the present invention includes a cutter head 1 and a handle 2 connected to the rear end of the cutter head 1, wherein the maximum outer diameter of the rear end of the cutter head 1 is The diameter is the same as the outer diameter of the handle part 2, and at least one annular groove 3 is provided on the side of the handle part 2 close to the head part 1, and an open elastic snap ring is installed in the annular groove 3 4. The outer diameter of the open elastic snap ring 4 is larger than the outer diameter of the handle part 2 . An improved straight knife for processing wood products of the present invention, since the maximum outer diameter of the cutter hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com