Novel end cover fixing device of centrifugal tube casting die

A technology of centrifugal casting and end cap fixing, which is applied in the field of metallurgical centrifugal casting, which can solve problems affecting product quality, low safety factor, and tube mold damage, and achieve the effects of improving furnace tube performance, improving process level, and saving billets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] specific implementation plan

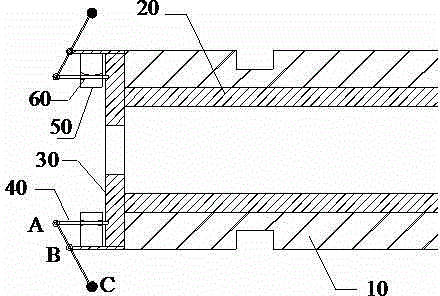

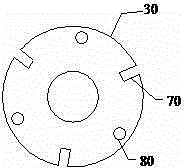

[0015] refer to figure 1 , a new type of centrifugal casting pipe mold end cap fixing device, the furnace pipe mold 10, the end cap 30, the movable connecting rod 40, the metal protection block 50, the two ends of the pipe mold 10 are installed with the end cap 30, and the outer side of the end cap 30 Movable connecting rod 40 and metal protection block 50 are set, and movable connecting rod 40 is divided into two sections by hinge 40A, and one end is fixed by hinge 40B, and is connected with metal ball 40C, and the other end passes through protection block 50 and clamps end cover 30, protects The block 50 is provided with a shrapnel 60, and the connecting rod 40 has a clamping effect when it passes through, and the movable angle is increased. The present invention relies on the centrifugal force to realize the locking of the end cover.

[0016] The furnace tube mold 10 of the present invention is provided with a fixed protection block 50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com