Distributing machine of water-permeable bricks

A technology of distributing machine and permeable brick, which is applied to supply devices, manufacturing tools, etc., can solve the problems of incomplete blanking, affecting processing efficiency, low blanking efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

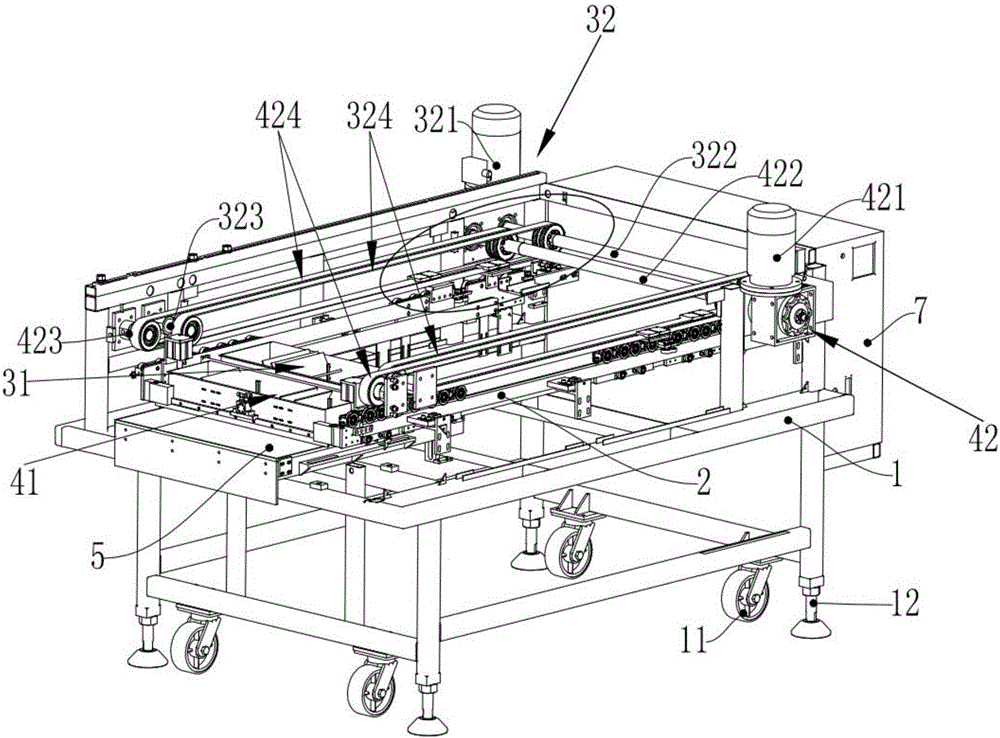

[0041] Such as figure 1 As shown, a permeable brick placing machine includes a frame 1 and a guide rail 2; the guide rail 2 is arranged on both sides of the frame 1;

[0042] It also includes a bottom material distributing device and a fabric distributing device;

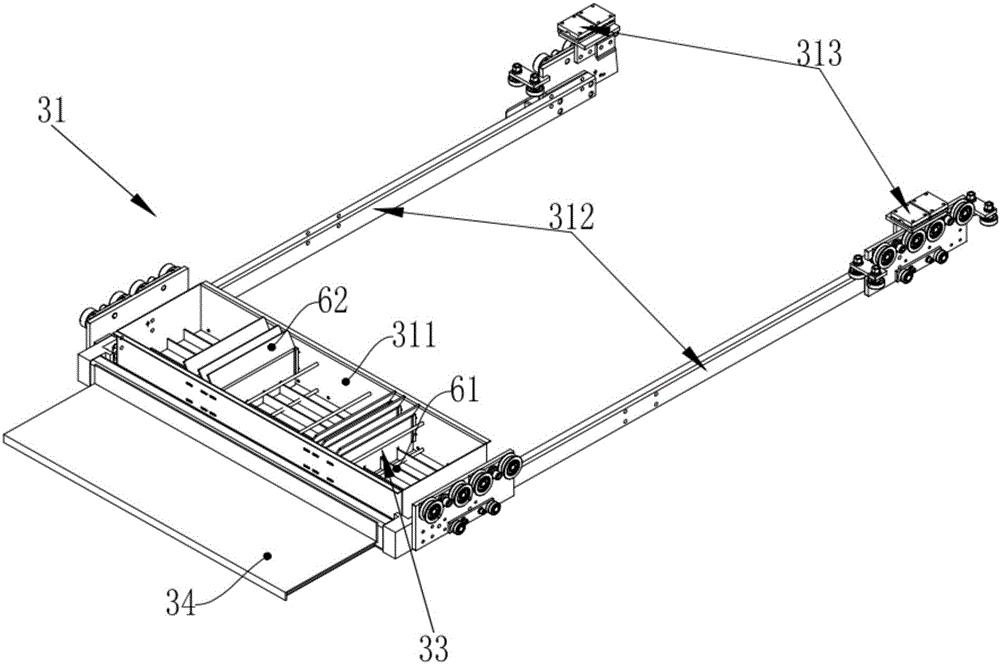

[0043] The bottom material distributing device includes a first material holding device 31, a first power device 32 and a bottom material scraping device 33;

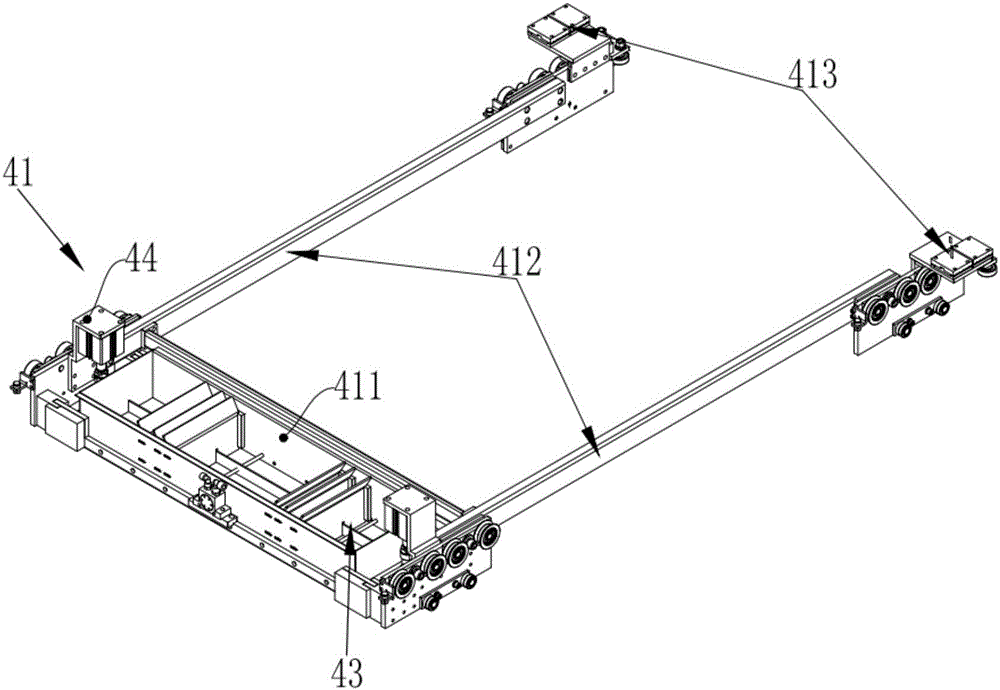

[0044] The fabric distributing device includes a second material holding device 41, a second power device 42 and a fabric scraping device 43;

[0045] The first power device 32 is arranged on the frame 1, the first material holding device 31 is arranged on the guide rail 2, the first power device 32 drives the first material holding device 31, and the bottom The material scrapin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap