Device for testing explosion and propagation characteristics of explosives

A test device and technology of propagation characteristics, applied in the direction of material explosiveness, etc., can solve the problems of high consumption of manpower and material resources, complex test process, affecting the acquisition and application process of thermobaric explosives, etc., to reduce the shock wave force and improve the safety factor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

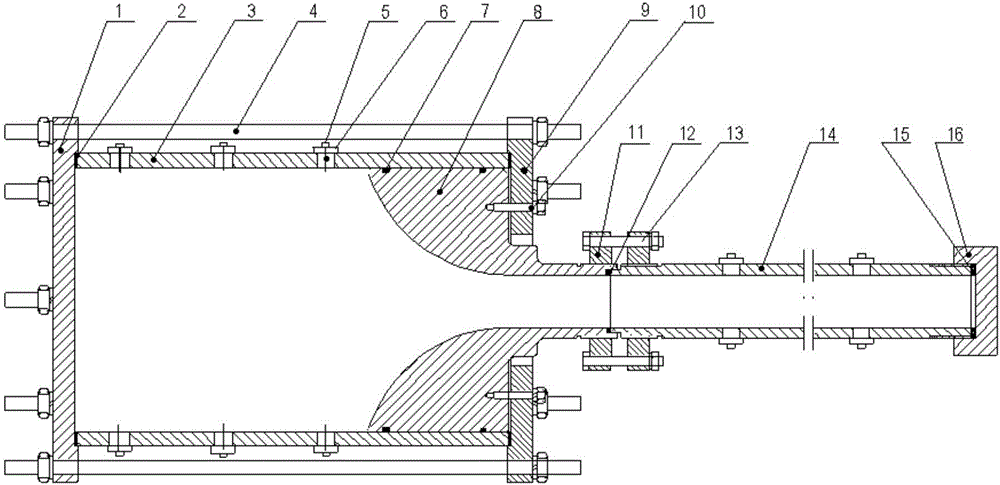

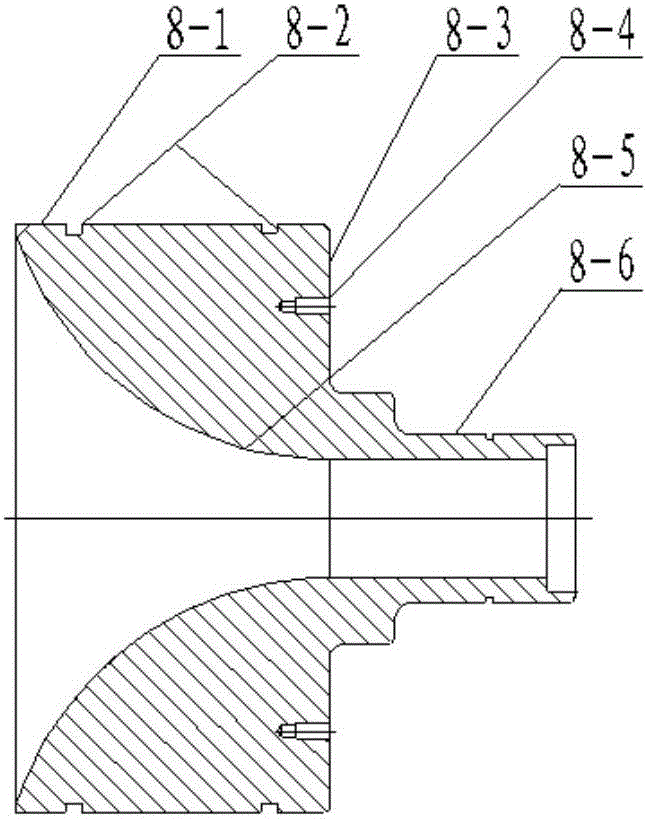

[0016] as figure 1 As shown, the preferred embodiment of the present invention includes a front cover 1, a large sealing gasket 2, a tank body 3, a stud 4, a sensor 5, a sensor mounting seat 6, an O-ring 7, a lining 8, and a rear end cover 9. Positioning screw 10, flange ring 11, small gasket 12, stud 13, pressure transmission pipe 14, sealing ring 15, pressure transmission pipe cover 16. The front end cover 1 is disc-shaped and made of explosion-proof glass, and its thickness is determined according to the formula 1 for calculating the wall thickness δ of the pressure vessel of the equipment:

[0017] δ = PD i ε [ σ ] t - p - - - ( 1 )

[0018] Among them: P: allowable stress; D I : container inner diam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com