An ultrasonic flaw detection test block for blade detection

An ultrasonic and blade technology, which is applied in the direction of material analysis, measuring devices, and instruments using sound waves/ultrasonic waves/infrasonic waves, can solve problems such as curvature changes, complex shapes, difficult calibration, and sensitivity determination, and achieve the elimination of sensitivity errors, Portable and well-structured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further explained below in conjunction with specific embodiments and accompanying drawings.

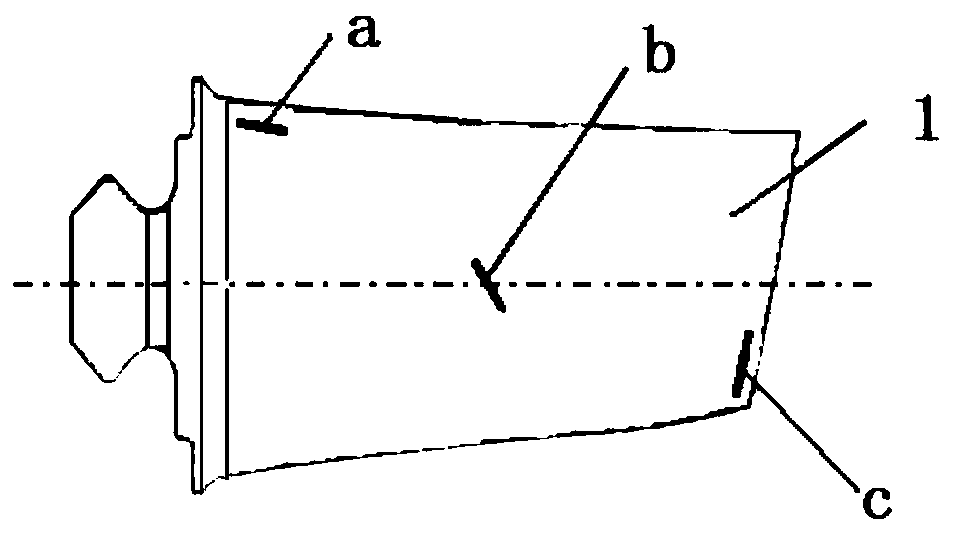

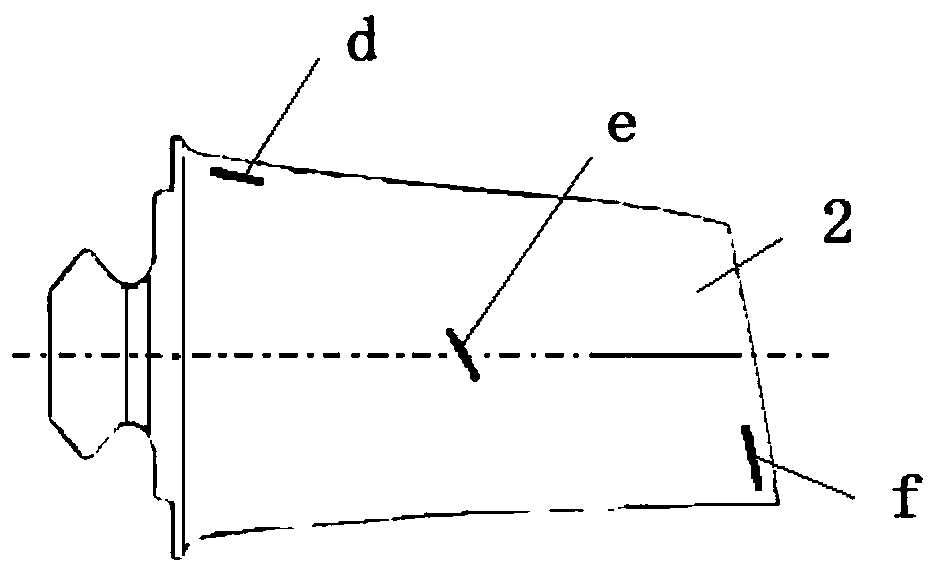

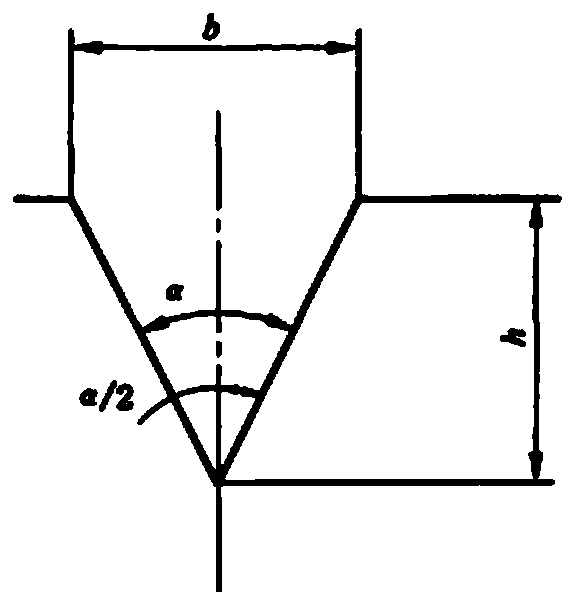

[0021] see figure 1 and figure 2 , the present invention comprises A-type blade test block and B-type blade test block, and the A-type blade test block and B-type blade test block are all the same as the material, structure and size of the detected blade, and the leaf back of the A-type blade test block 1. The first artificial defect a and the third artificial defect c are respectively arranged at the position not greater than the distance from the edge of the blade body than the detection blind area, and the second artificial defect b is arranged at the geometric center of the leaf back 1; the leaf pot of the B-type blade test block A fourth artificial defect d and a sixth artificial defect f are provided on the parts of the surface 2 that are not greater than the distance from the edge of the blade body than the detection blind zone, and the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com