A kind of oblique tooth surface gear transmission pair and tooth width geometric design method

A technology of gear transmission and tooth surface, which is applied in belts/chains/gears, mechanical equipment, components with teeth, etc., can solve the problems of incomplete geometric design of tooth width, large vibration and noise, and load capacity of oblique tooth surface gears. Bad question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069]The present invention will be further described in detail below in conjunction with the accompanying drawings, which are explanations rather than limitations of the present invention.

[0070] like figure 1 As shown, it is a transmission pair of point contact oblique tooth surface gear of the present invention, including oblique tooth surface gear and involute spur gear meshing with each other, the oblique tooth surface gear and involute spur gear point contact meshing transmission, The tooth line of the oblique tooth surface gear is approximately oblique, and the tooth line and the radial direction form an inclination angle, and the inclination angle γ does not exceed 25°; the involute spur gear is formed along the pitch cone of the oblique tooth surface gear The direction of the inclined angle is installed.

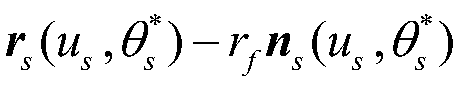

[0071] like figure 2 As shown, it is the tooth width geometric design method of the oblique tooth surface gear of the present invention, comprising the followi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com