Wire support fixing mechanism with spacing changing along with wind

A technology for fixing mechanisms and wires, which is applied to the installation of devices for maintaining the distance between parallel conductors, electrical components, cables, etc., and can solve problems such as broken wires, circuit failures, and wires that cannot be moved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] like Figure 16 , 17 As shown, it includes a fixed frame 46, a crossbeam 45, and a vertical beam 47, wherein the crossbeam 45 is installed on the top of the vertical beam 47, and two fixed frames 46 are symmetrically installed at both ends of the crossbeam 45.

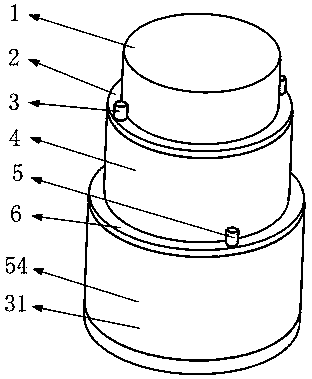

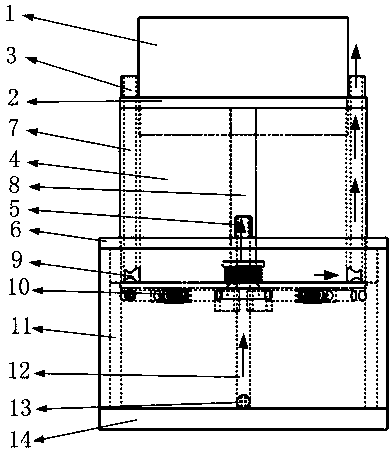

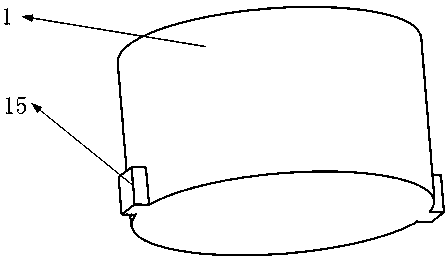

[0049] like Figure 17 As shown, the structure of the above-mentioned two fixed mounts 46 is the same, for any one fixed mount 46, as Figure 18 As shown, it includes wire fixing mechanism 48, fixing ring plate 49, radial support bar 50, beam cover 51, fixing mechanism first support 52, fixing mechanism second support 53, first displacement cylinder 54, power generating mechanism support 55, The first generating mechanism 56, the second displacement cylinder 57, and the second generating mechanism 58, wherein the beam cover 51 is installed on one end of the beam 45, and one end of the three radial struts 50 is evenly installed on the outer edge surface of the beam cover 51 in the circumferential direction , t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com