A circuit board clamping device

A fixture device and circuit board technology, which is applied to auxiliary devices, devices for coating liquid on surfaces, manufacturing tools, etc., can solve the problems of high cost, inability to detect whether the circuit board is properly clamped, and inability to prevent repeated gluing of the circuit board, etc. Achieve the effect of reducing dispensing and welding costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

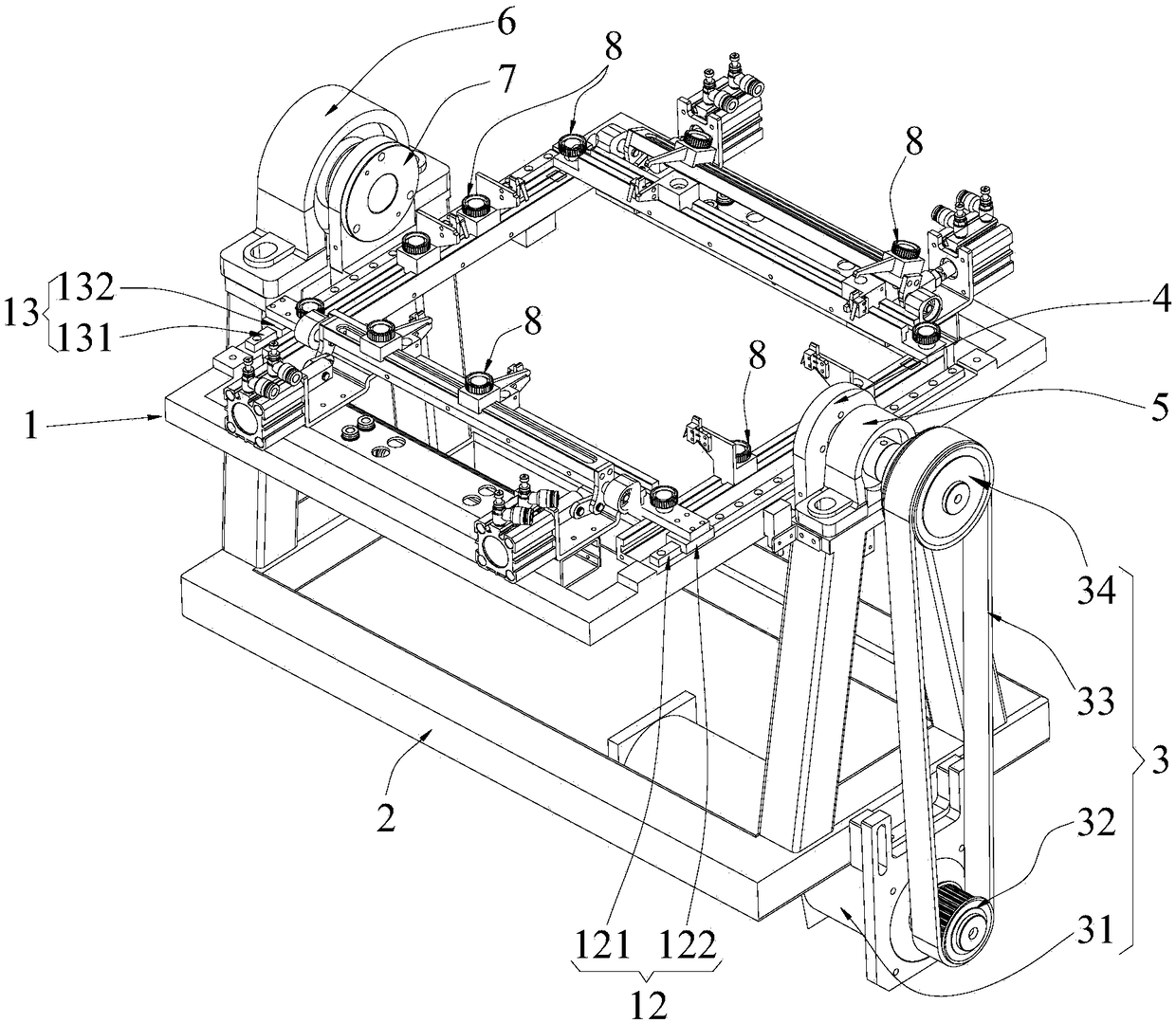

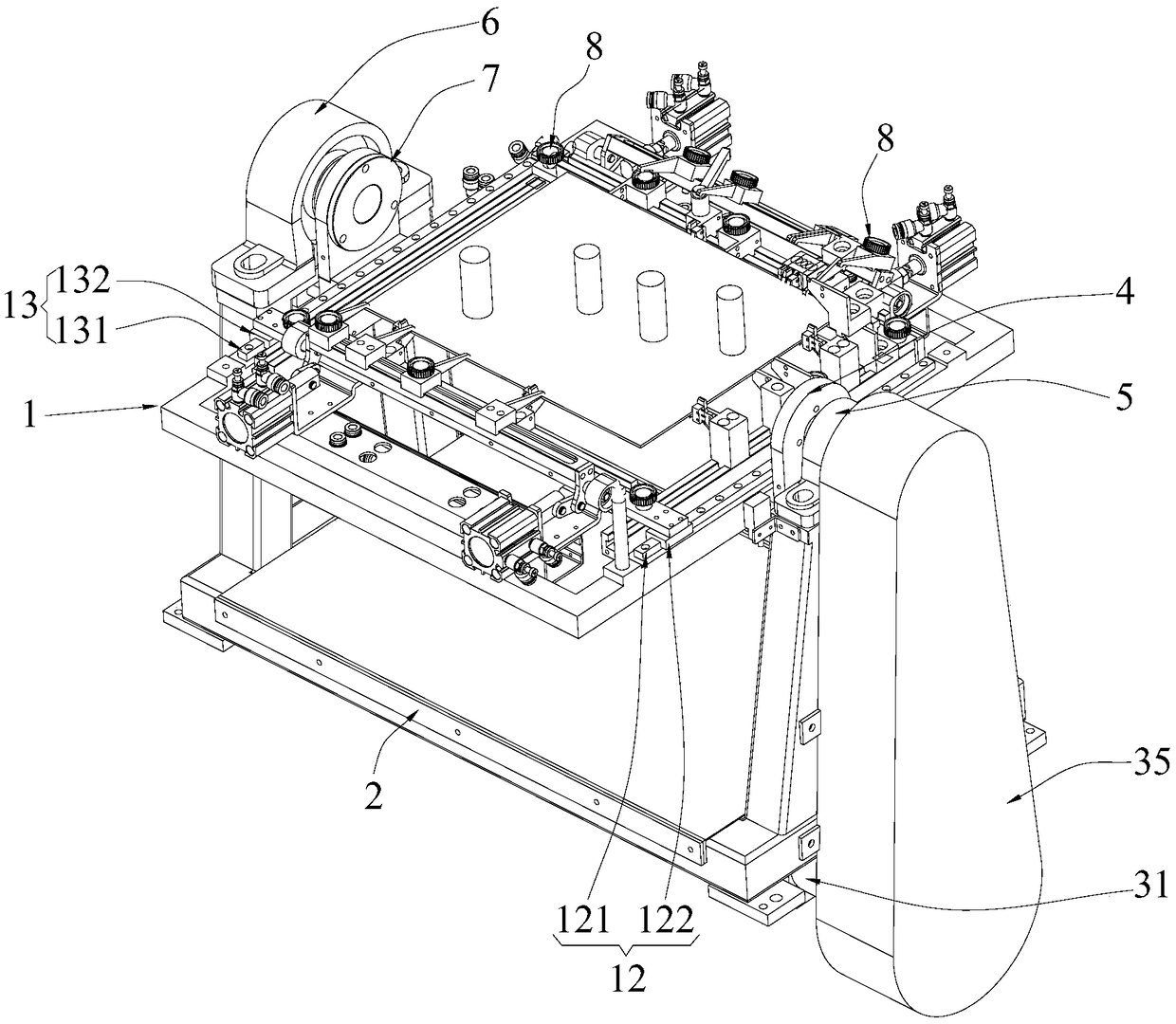

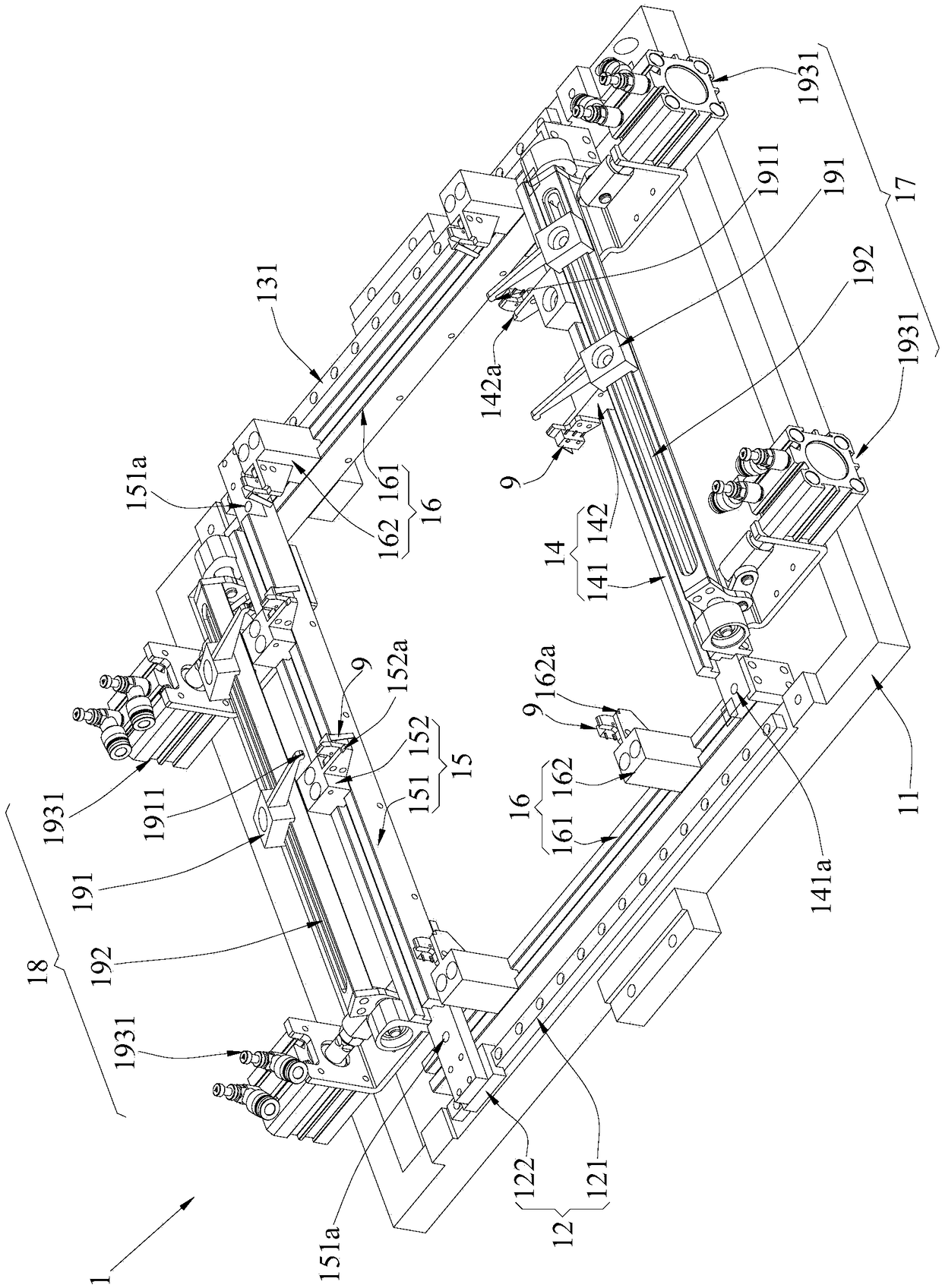

[0026] Such as Figure 1 to Figure 7As shown, the circuit board fixture device of the present invention is provided with a rotary table assembly 1, a fixture frame 2, a power system 3, a driving shaft assembly 4, a driving shaft bearing seat 5, a driven shaft bearing seat 6, and a driven shaft assembly 7 And detection system, wherein, the rotating table assembly 1 can clamp and fix the circuit board; the driving shaft bearing seat 5 and the driven shaft bearing seat 6 are fixed on the fixture frame 2 in a coaxial manner, and the driving shaft assembly 4 is installed on the driving shaft On the bearing seat 5, the driven shaft assembly 7 is installed on the driven shaft bearing seat 6, the turntable assembly 1 is fixed between the driving shaft assembly 4 and the driven shaft assembly 7, and the power system 3 and the fixture frame 2 are relatively fixed, Moreover, the power system 3 can drive the turntable assembly 1 to rotate at any angle around the axis of the drive shaft be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com