The internal support method of the automatic welding internal support device for the circular seam of the tank barrel section

A technology for automatic welding and barrel sections, which is applied in the direction of auxiliary devices, welding equipment, auxiliary welding equipment, etc., and can solve the problems of lack of available internal support devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

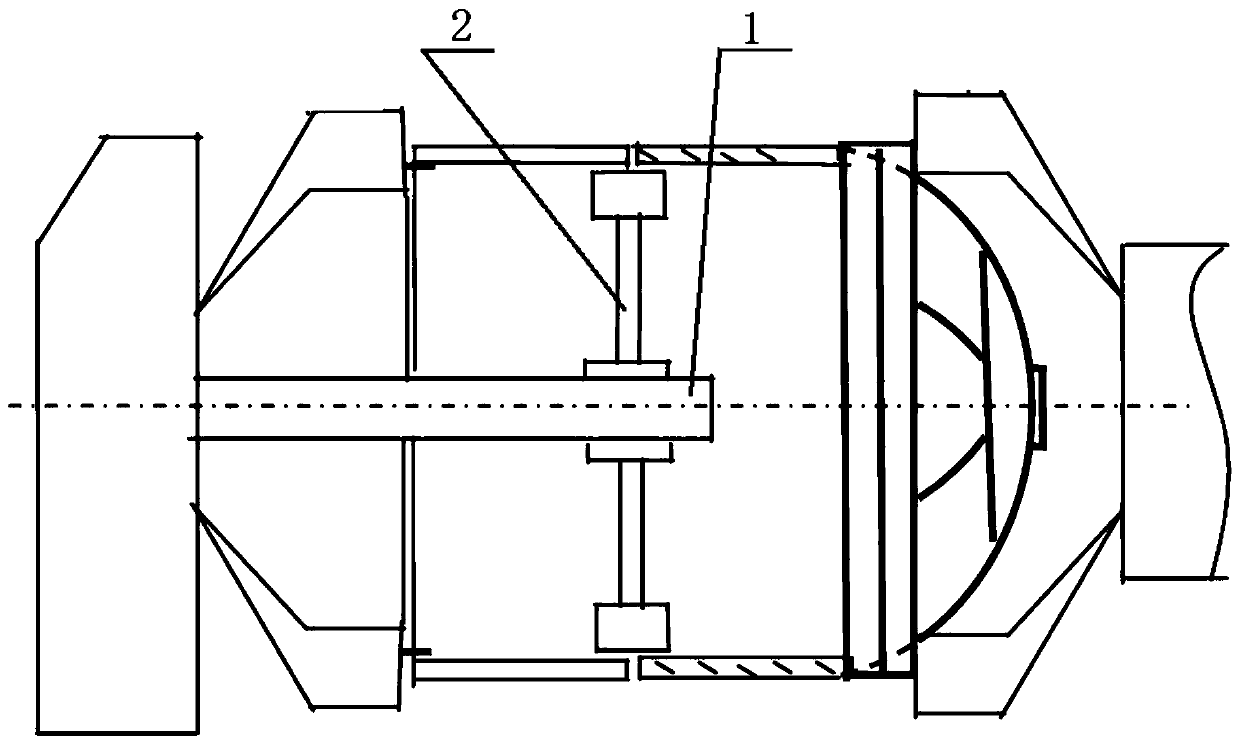

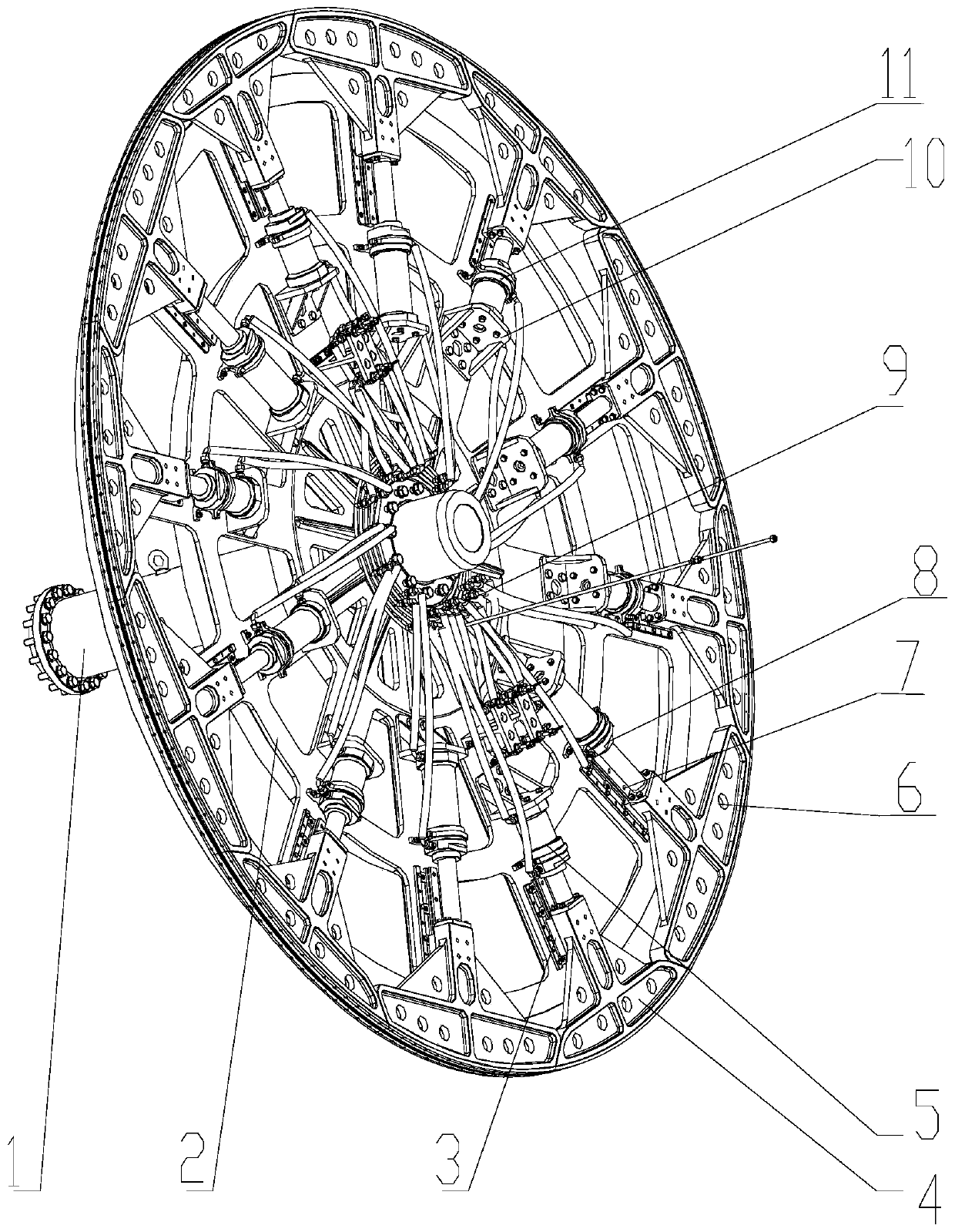

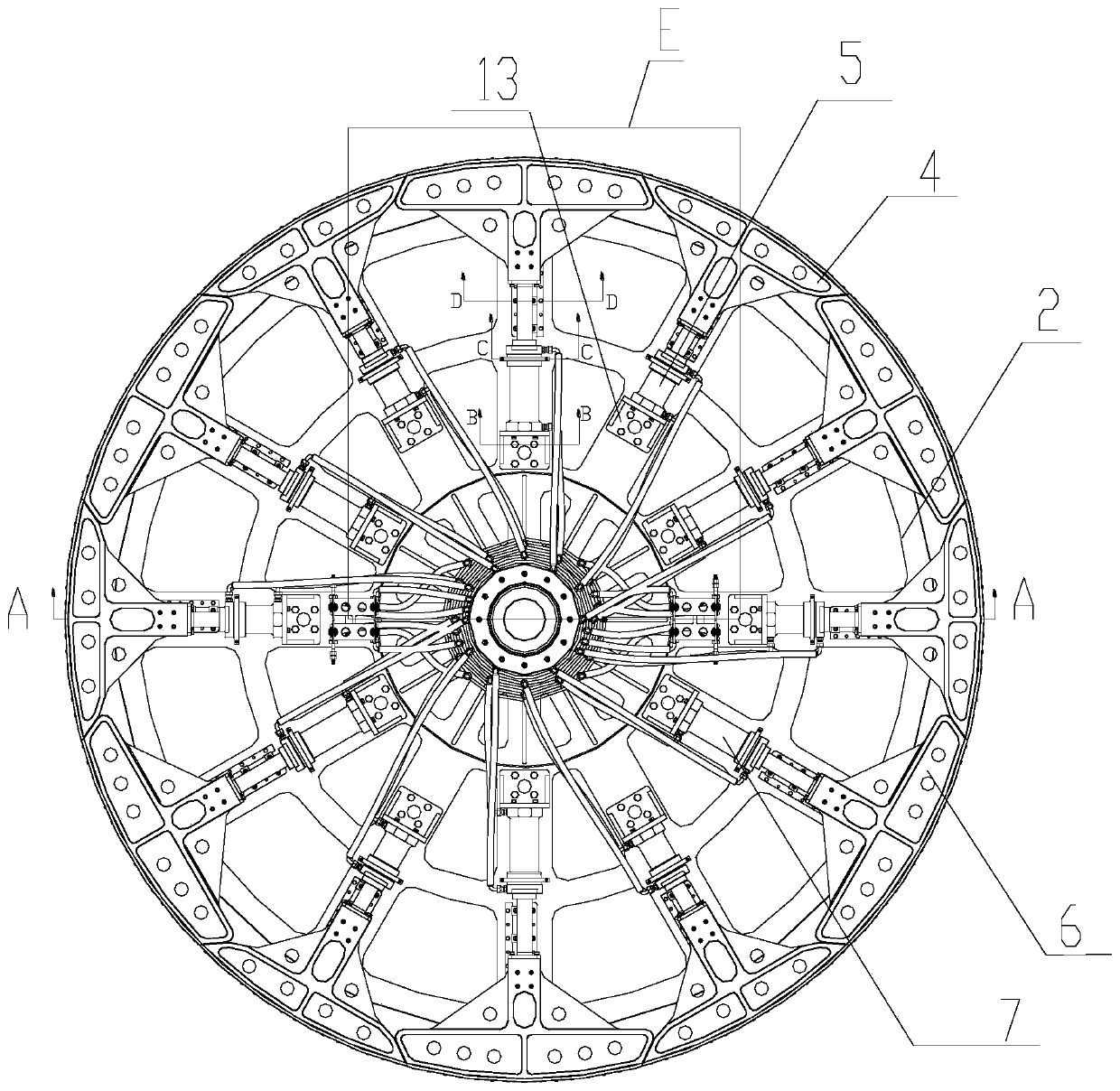

[0033] Example 1: see Figure 1 to Figure 15 ,in, figure 1 It is a structural schematic diagram of the present invention when it is used, and it is used for automatic welding of the girth seam of the barrel section of the storage tank.

[0034] An automatic welding internal support device for the circular seam of the tank barrel section, including a vertically arranged main shaft, and a horizontal faceplate 2, the middle part of the faceplate 2 is fixedly connected to the main shaft through a bushing 13,

[0035] The upper surface of the faceplate 2 is provided with several long linear guide rails 7 and several short linear guide rails 3 along its radial direction, and the long linear guide rails 7 and short linear guide rails 3 are staggered and evenly distributed.

[0036] The long linear guide rail 7 is connected to an inner arc-shaped support block 6 through a slider, the end of the inner arc-shaped support block 6 away from the main shaft is an arc-shaped surface, the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com