microstep robot

A robot and micro-step technology, applied in the field of robotics, can solve the problems of high ground flatness, unsatisfactory requirements, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

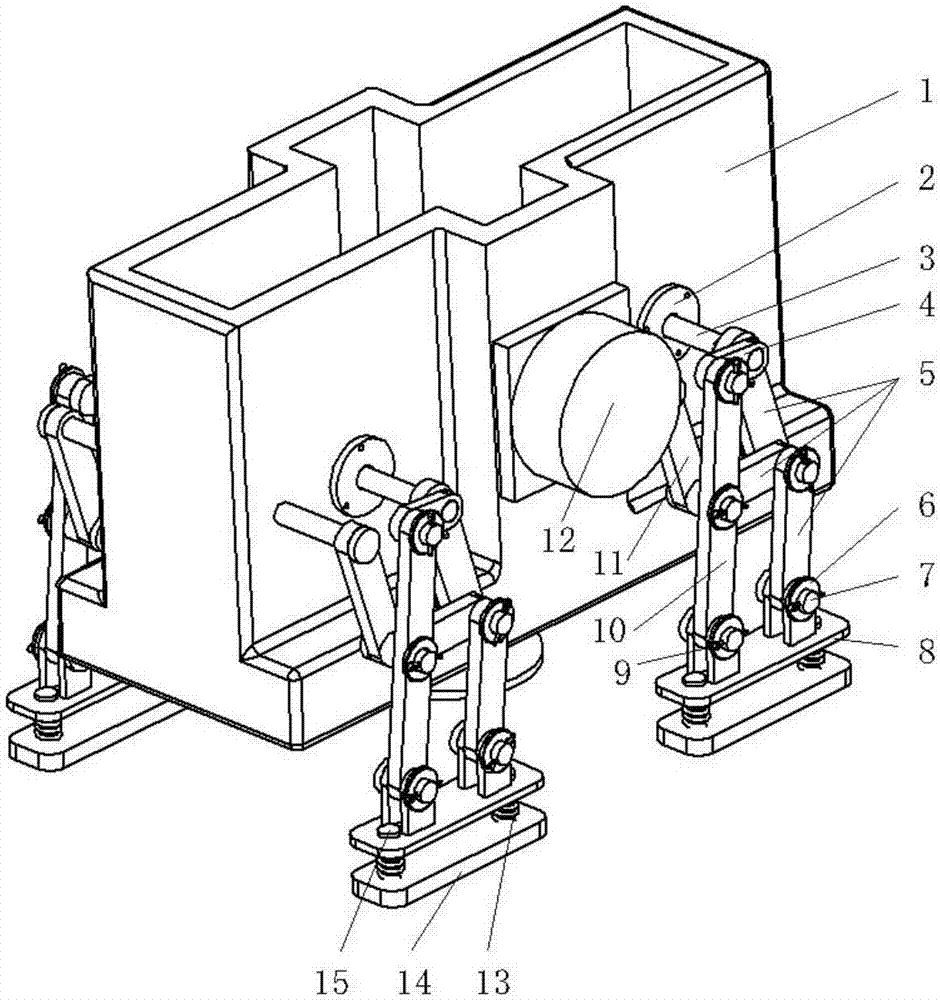

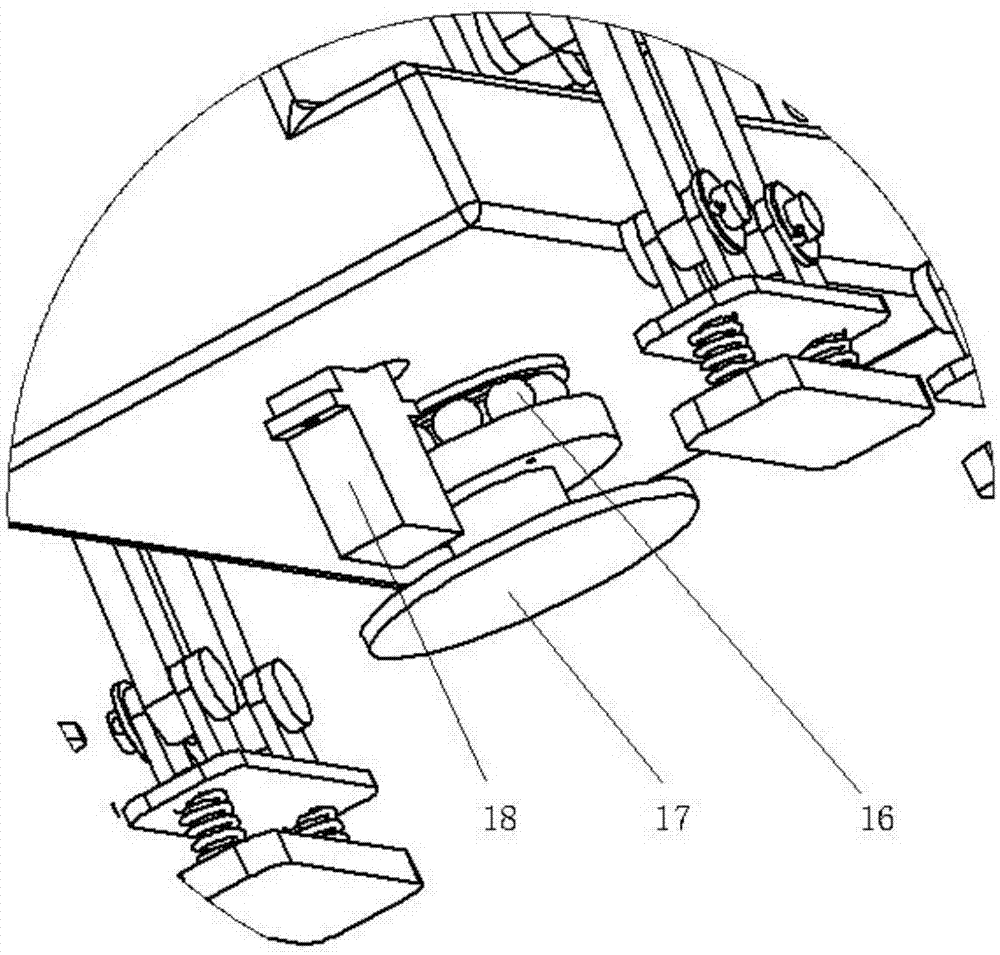

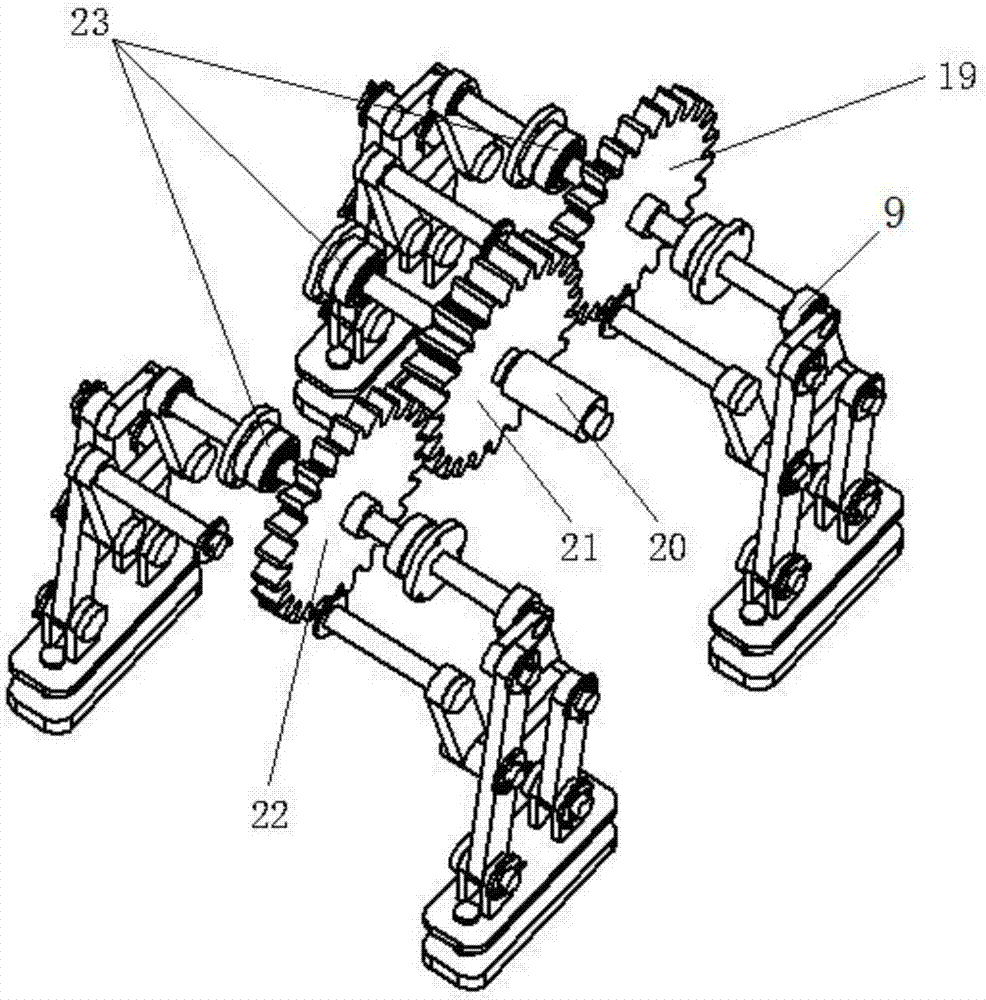

[0018] Such as Figure 1 to Figure 5 Shown, a kind of micro-stepping robot comprises housing 1, advancing motor 12, traveling mechanism and steering mechanism, and steering mechanism can realize the rotation of robot whole, changes the direction of advancing, and advancing motor 12 is installed on the housing 1; The walking mechanism includes a gear transmission mechanism, a Chebyshev linkage mechanism and a foot 14;

[0019] Wherein, the gear transmission mechanism includes a front drive gear 22, an intermediate gear 21 and a rear drive gear 19 which are meshed in sequence. 21, and then the intermediate gear 21 transmits the rotational motion to the front and rear drive gears to realize the same direction and constant speed rotation;

[0020] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com