Turnover device

A technology of turning device and turning shaft, which is applied in the direction of transportation and packaging, metal processing, metal processing equipment, etc., and can solve the problems of easily damaged products, occupying production space, and increasing the length of assembly lines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

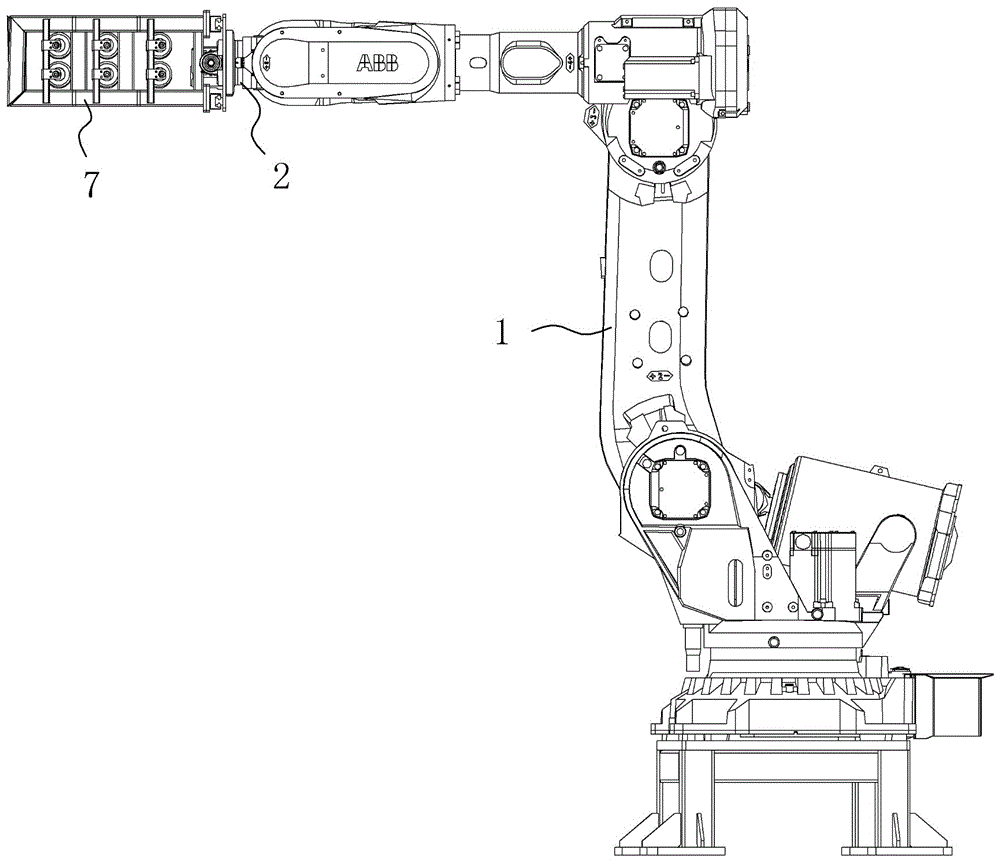

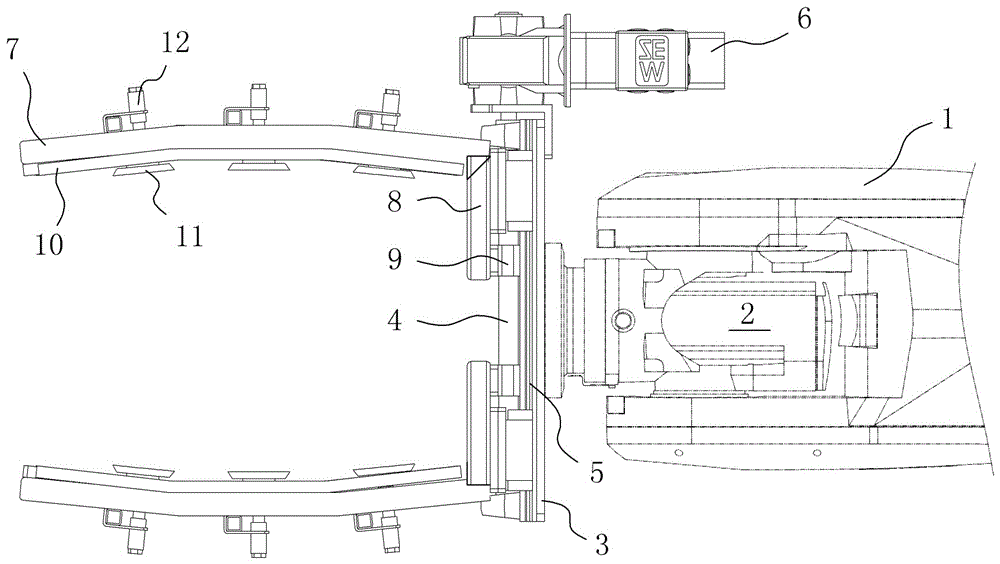

[0009] A kind of overturning device, comprises overturning robot 1, is provided with overturning axis and the overturning seat 2 that rotates around the overturning axis on the robot, and the end of overturning seat is equipped with the overturning plate 3 that vertically is arranged, and the direction is parallel to each other wire is installed on the overturning plate Rod 4 and slide rail 5, in addition drive motor 6 to drive the screw to rotate and two splints 7 for clamping the product. Two ends, one end of splint is provided with the slide seat 8 that moves along slide rail, and the screw nut 9 that cooperates with screw mandrel is housed on the slide seat, and the installation direction of two screw nuts and screw mandrel is opposite.

[0010] In the overturning device, the drive motor 6 is a servo reduction motor, so that the overturning device can clamp the product more smoothly; the inner side of the splint 7 is provided with a flexible backing plate 10, and when the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com